Dusty Hawk has been working on transmissions for many years. His dad worked at a dealership in the '60s, and before he was out of high school, Dusty was changing oil at the dealership. By 1975 Dusty was a service mechanic, but around 1989 he moved to the complicated world of transmissions, just like his dad.

It might not have been intentional, but Dusty just seemed to understand transmissions. People started asking for him by name, and customers came from far away to use his services. The first time a customer brought in a diesel truck transmission and said he wanted it to survive drag race runs in the high 13s, Dusty thought it was a joke. "I thought, who would do this?" He did a lot of research and tinkering and figured out how to get a 7,000-pound pickup down the track fast. "I never thought [the sport] would get big," he added.

But it did. As we all know, the sport of diesel pickup drag racing, sled pulling, dyno day competitions, and just general carnage has grown by leaps and bounds over the past years. The '90s were all about Dodge transmissions for Dusty, and in 1998 he started doing business under the Hawk Torqueflite Specialties banner.

In 2003 Dusty and his wife Marianne decided they could make a go of it with their own full-time business and Hawk Torqueflite Specialties (HTS) was on its way to establishing itself on a national level. Remembering the early days of working on Dodge transmissions, Dusty says with a bit of a laugh, "Now 99 percent of what we do is performance."

The crew at HTS does some work with injectors and pumps, but mostly they specialize in transmissions. And if you want to further narrow it down, they are about the most sophisticated Dodge transmission experts you can find. Oh sure, they work on other transmissions too (even have an Allison specialist on board), but the Dodge dudes know this is the place to go when you're starting to push the limits or don't understand that limits exist.

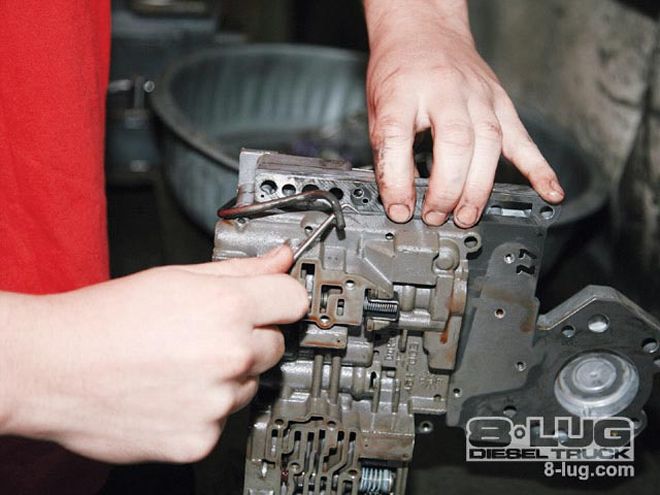

"We learn something every day," Dusty said as he showed us around the shop. "There are always new products and new ideas." If you're not in a hurry, the best time to build a transmission is in the summer when work slows down a bit. If you're in a hurry in the winter (like most people seem to be), then it might be a bit more crowded at HTS. Still, they're going to get the work done. HTS does, on average, 250-plus transmissions every year. Plus they do a lot of valvebodies for those who have everything else covered.

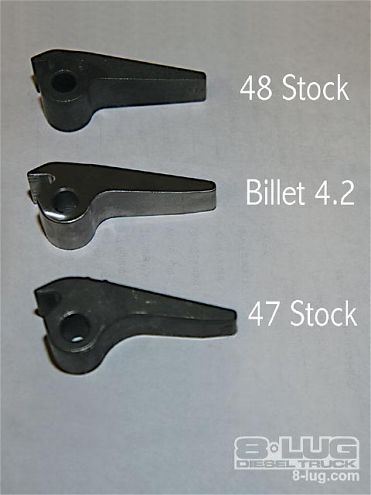

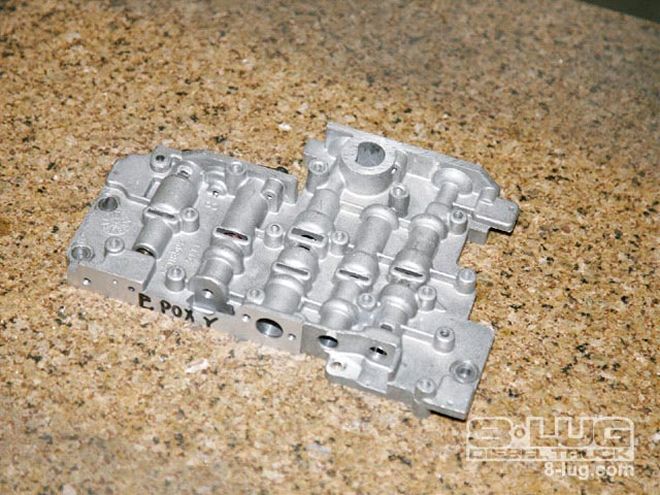

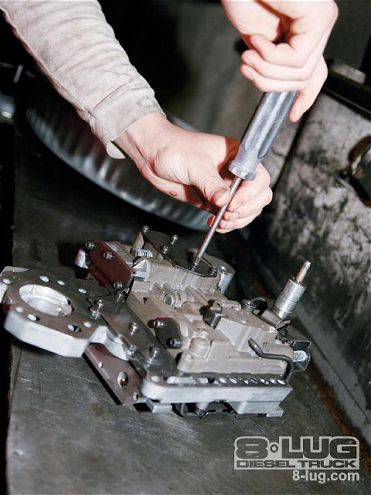

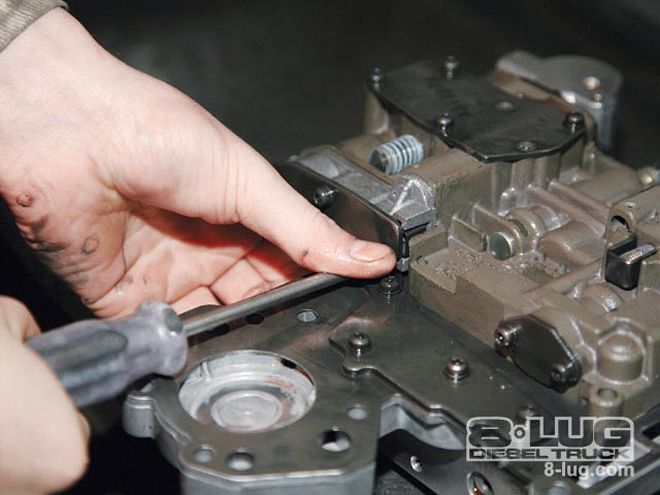

We noted a lot of interesting things going on while visiting HTS in Lowell, Michigan, but Dusty was careful not to reveal too much. Some special parts and some certain ways of doing things are the kind of details that make HTS transmissions last, and he doesn't want to give up that info to just anyone. Here's one example: Chrysler valvebodies are almost always very warped when they come out of the transmission, so one of the most important tasks is to get it flat using a granite surface that HTS has. It's time consuming but makes a difference.

How do you know if you need to upgrade your transmission? "I've seen guys with 300 hp break everything and guys with 600 hp break nothing. I guess it depends on how you use it. I can tell you this, 20-year-olds break more than 40-year-olds," Dusty said.

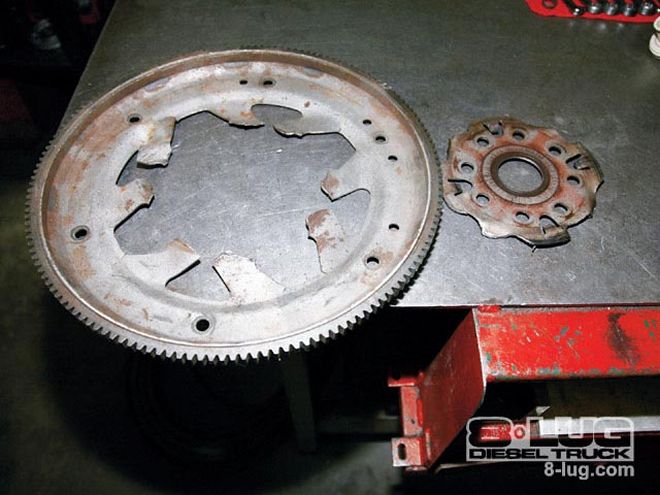

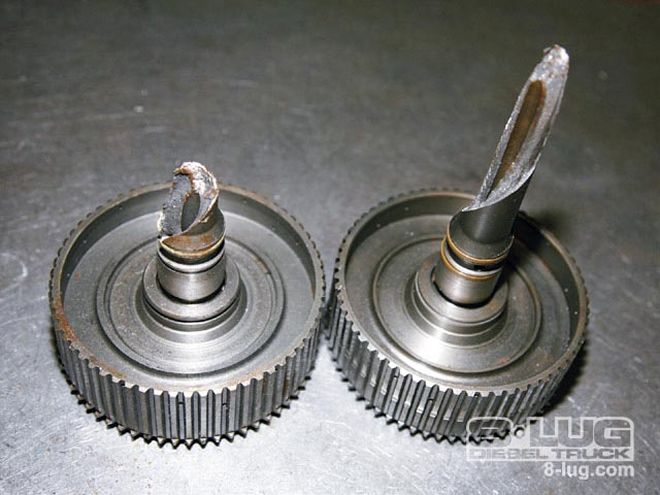

There's plenty more to be learned, so take a look at the photos we took while visiting and you'll get an idea what HTS is all about. And if you need a stout transmission built, now you know a good place to go.

5 Things You Should modify

(In Order Of Importance)

1. Valvebody

2. Converter

3. Input

4. Flexplate

5. Double-deep pan (for towing especially)

Product Profile:

Hawk Torqueflite Specialties

877/630-9122

www.htstransmissions.com