QuestionQUESTION: I have a 2000 Blazer. While driving the veh suddenly shut off. I had veh towed to a rep facility. I examined the vehicle very carefully and there were NO fuel leaks. Rep fac stated that when they hooked up the test equip on the fuel rail, there a fuel leak which caused a fire. Now they say that the connection on the fuel rail was faulty and want to charge $300 to rep the fire damage before that diagnose the original problem. I think the tech installed the test equip wrong or the test equip itself leaked which caused the fire. What is you idea on this. thks, Charlie Moore Rocklon, CA

GM fuel pump

GM fuel pump

ANSWER: Hey Charlie,

First off I want to start this email stating I don't want to beat up a repair facility. Especially when I am not the inspecting or repairing technician. The message I am going to write is solely based on personal experience testing and repair fuel systems on GM vehicles in general. It is basically coming down to whether or not the service adviser is telling the truth or not. I would expect that his service facilities equipment and integrity are to par with any establishment that has a good work ethic and mission statement.

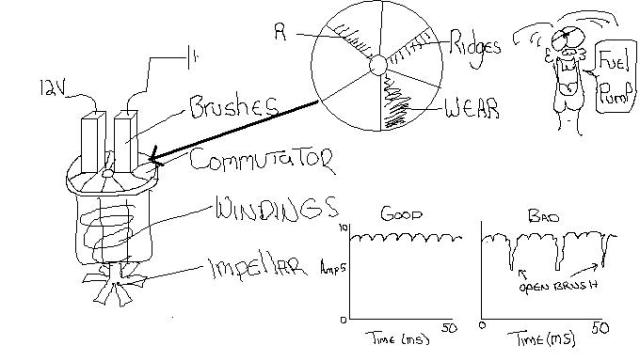

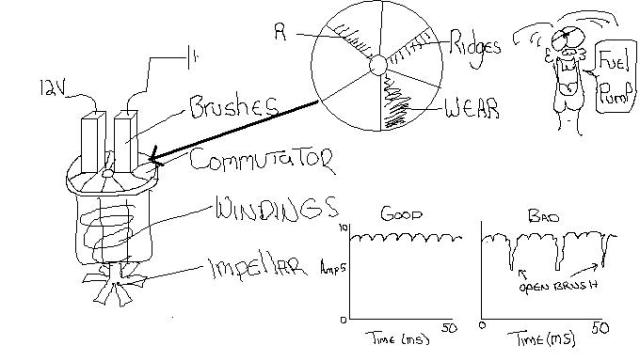

GM fuel pumps are by far and wide the worst pumps built. The type of brush and commutator assembly the engineers designed is not only prone to failure but EVENTUALLY WILL FAIL. (See attached picture I drew in paint)

Checking fuel pressure on a GM pump can be dangerous too. The schreader valve (1/4" pipe threaded spring loaded valve core design) is located near the distributor and exhaust manifold. Hooking a fuel pressure gauge up to a 60psi system with the pump running or rail charged will spew fuel all over the manifold, distributor, your face and engine compartment. If you fumble with the connector and don't get it to latch you will put fuel from the front license plate to the rear plate. I have run into some close calls myself and have developed a new procedure that ALL my technicians must follow when testing a pump.

The first thing we do is jump the fuel pump relay with a test lead that is long enough to put a low amperage probe on. We then give the tank a boot. This usually sends a shock wave to the pump and gets it going. On the oscilloscope we can monitor brush and commutators as well as calculate amperage and revolutions per second to a tee. It is unobtrusive and very foolproof. I can tell you with this test whether a pump is going to fail even if the car is running perfect (see attached photo). This is not a mystery anymore and any well trained technician should be able to do current ramping but many still have no clue what it is and prefer to stick to an analogue gauge.

In cases where we still have to check pressure we use a pressure transducer and electronic gauge package. With the key off the fuel rail is purged into a cup and rags to soak up any excess fuel.

What does the service facility have to lose by lying? Thats the big question. If they are telling the truth they will be confident enough to give you your old parts with the knowledge you will be taking them somewhere else for a second opinion and give you a reasonable explanation. If they are lying they will make up excuses as to where your parts are. Its a tough call but I have yet to see any of those systems fracture. It is a CPI unit that has two fuel lines that go to the CPI module. The entire injector assembly in inside the upper plegnum and is not exposed to anything. Get your parts back, take some pictures and send them to me.

Wayne

---------- FOLLOW-UP ----------

QUESTION: To Wayne,

Regarding my initial e-mail. The repair facility is a 76 Service Station, not a reputable GM Dealer.

They are trying to tell me that when they hooked into the fuel rail, the schreader valve leaked fuel onto the manifold, which caused the fire. From your response, it appears that the technician may have as you put it, "fumble with the connector" which caused the leak. Once you connect to the schreader valve, do you have to turn it to open it or is the connection automatically opened? Could they have opened the valve to far, which caused excess fuel to be "leaked"? Thanks again, Charlie Moore - Rocklin, CA

AnswerHi,

The test port on the fuel line is very similar to a tire valve and works the same way with a spring loaded valve. There is a flange on the line that your fuel test gauge seals to usually with an o-ring. If anything there is really no way this can leak with a gauge hooked up unless the flange is damaged or the equipment is not sealing properly. The line and fitting is made from steel and should not be damaged unless the flange was scored or scratched. If the gauge is on properly and tight it will not leak. There really can't be anything wrong with the fuel line fitting unless they removed the gauge and the valve did not pop up and seat. That should have been noticed before it was started though. The pressure drop with a large leak would be enough to not allow it to start anyway. The story has more holes than the fuel line to my comprehension anyways.

Wayne