The suspension system, while not absolutely essential to the operation of a motor vehicle, makes a big difference in the amount of pleasure experienced while driving. Essentially, it acts as a "bridge" between the occupants of the vehicle and the road they ride on.

The term suspension refers to the ability of this bridge to "suspend" a vehicle's frame, body and powertrain above the wheels. Like the Golden Gate Bridge hovering over San Francisco Bay, it separates the two and keeps them apart. To remove this suspension would be like taking a cool dive from the Golden Gate: you might survive the fall, but the impact would leave you sore for weeks.

Think of a skateboard. It has direct contact with the road. You feel every brick, crack, crevice and bump. It's almost a visceral experience. As the wheels growl across the pavement, picking up a bump here, a crack there, the vibration travels up your legs and settles in your gut. You could almost admit you were having fun, if you didn't feel like you were gonna toss your tacos at any second.

This is what your car would feel like without a suspension system.

Before we get into the individual components that make up a vehicle's ride support, let's take a look at a basic principle of design: solid axle vs. independent suspension.

Solid axle suspension (also known as rigid beam, or rigid axle) is the most elementary form of connecting the upper and lower halves of a vehicle. As the name implies, it utilizes a single piece of metal -- a common axle for both wheels -- sprung beneath the car's undercarriage. Pivots located between the axle and the wheel spindles allow the wheels to swivel on each end.

In solid axle suspension, because both wheels share the same axle, the up or down movement of one wheel causes a like movement in the other wheel. They respond as one unit. As you can imagine, this doesn't make for the most comfortable ride. Even though solid axle designs utilize springs to soften their inherently harsh ride characteristics (more on different spring setups below), they still bump along like a brick outhouse. So why use them at all? Well, strength, for one. Because of the unitized construction, solid axle suspension systems offer incredible load bearing capacity. They also handle uneven roads superbly. You'll find them in trucks and offroad vehicles.

A modified form of the solid axle design is called Twin-I-beam suspension, or semi-rigid axle. In this setup, two rigid axles -- one for each wheel -- take the place of a single axle. This design offers many of the strengths of the solid axle design, with a slightly softer ride. You'll find it used primarily in the front end of light trucks.

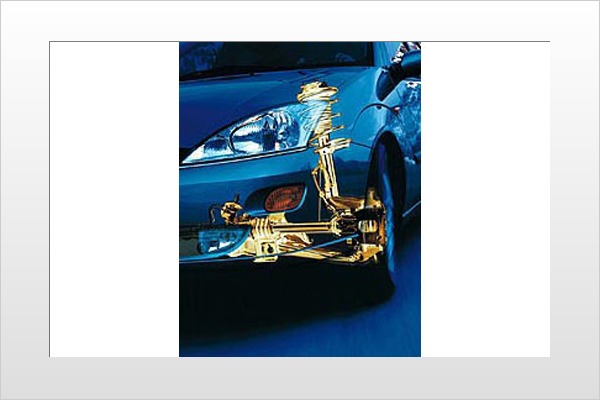

The other main design is called independent suspension. As the name suggests, independent suspension assemblies offer a separate "bridge" for each wheel. They deliver the best ride characteristics by far, and are found most frequently in passenger cars, minivans, and other street vehicles. This is the most popular kind of suspension system in use today. If you like the "smoothness" of your car's ride, we can almost guarantee it has independent suspension.

In addition to axles, wheels and tires, today's suspension systems utilize two other components that are critical to safe and comfortable driving: springs and shock absorbers.

Springs

A car's springs are the central part of the suspension. There are different designs of springs, such as torsion bars and leaf springs, but nearly all of today's passenger cars use coil springs at all four corners. A lot of trucks use coil springs too, with leaf springs for heavier load capacity typically found on a truck's rear suspension system.

Springs absorb and store road shock caused by bumps, dips, cracks, and so forth (remember the skateboard analogy). They absorb this shock by either compressing or extending. When a car's wheel goes over a bump and gets pushed upward, the spring absorbs that additional load, keeps the road shock from reaching the chassis, and makes sure the tire maintains contact with the pavement.

How much a spring compresses or extends is determined by its "spring rate." Spring rate is measured in pounds per inch of deflection; for example, 100 pounds per inch. So, say a load of 200 pounds is applied, the spring will deflect 2 inches. Spring rate comes from various factors. For a coil spring, this includes the number of active coils, the diameter of the coils, and the diameter of the spring wire. The fewer coils a spring has, the higher the spring rate it will have.

The design of a spring affects how well the vehicle will ride and handle. A spring that absorbs lots of energy will generally offer a comfortable ride. After all, it can absorb most of the road shock (energy) that is being generated by the road surface. But there are always engineering trade-offs. This kind of spring generally requires a higher vehicle ride height, which will cause the vehicle to feel unstable during cornering. This instability is because the more distance a spring compresses or extends, the more the vehicle "rolls" around on its suspension. This rolling is called weight transfer, and it is caused by centrifugal force acting on the weight of the vehicle as it goes around a corner. Weight transfer can overload a tire's grip, which ultimately hurts traction, and therefore handling.

Shock Absorbers

The other main part of a car's suspension is the shock absorber. Contrary to its name, a shock absorber plays a minimal role in absorbing impacts taken by the suspension. That's the spring's job. A shock absorber dampens road impacts by converting the up and down oscillations of the spring into thermal energy.

People who live and breathe shock absorbers don't like the term shock absorbers; they prefer "dampers." The unwashed masses -- that's you and me -- just call them shock absorbers.

Without a shock absorber, a spring that has absorbed energy will release it by oscillating at an uncontrolled rate. The spring's inertia causes it to bounce and overextend itself. Then it recompresses, but again travels too far. The spring continues to bounce at its natural frequency until all the energy originally put into the spring is used up by friction. This effect can be quite detrimental to the stability of a vehicle.

Confused? OK, here's an analogy. If you have a Slinky lying around -- and who doesn't these days? -- you can use it as an example. Hold up a compressed Slinky in the air with your hand. Now hold just one end and let the other drop. The Slinky will absorb the potential energy caused by gravity (just like how a car's spring absorbs road shock) and then bounce up and down, up and down (aka: oscillate), for a long time. This what an automotive spring does if it doesn't have a shock absorber attached to it.

Perhaps you've heard the word "strut," or, more formally, MacPherson strut. Struts are simply shock absorbers used as major structural members. For struts, the shock absorber is placed inside the coil spring. In addition to saving space, it often offers cost-saving advantages for auto manufacturers. Many cars use a strut design.

Shocks and struts help control how fast the suspension is allowed to move, which is important for keeping the tires in contact with the road. Most shock absorber designs have more resistance during the extension (rebound) cycle than the compression cycle. This is because the extension cycle controls the motion of the vehicle's sprung weight (half of the suspension and everything else above the suspension). The compression cycle, on the other hand, controls the motion of unsprung weight (wheels, tires, brakes, and half of the suspension). Obviously, there is a lot more weight in the upper part of the car than unsprung weight in the lower part of the car.

So there you have it -- the basics of automotive suspension. We realize this is a simplistic view of a complex system. In our next chapter in the series, we'll get a little more technical and a little more specific, looking at particular spring and suspension setups, and the advantages and disadvantages of each.

Until then, keep your eye on the road, and watch out for those potholes.

Suspension Basics I: Shake, Rattle and Roll Suspension II: Still Rocking After All These Years Suspension III: Active Suspension Systems Suspension IV: Improving Your Suspension