First Drive Review

First Drive Review

Let's imagine for conversation's sake that you've squirreled 400 large under the Beautyrest and are now looking to blow it on a supercar. A Ferrari F50 is too obvious, and a Bugatti EB110 is ridiculous. A scruffy McLaren F1 is in the price range, but the thing is so exotic that the tires probably require imported air. Anything more serious than a popped fuse puts it on the first steamer home to Blighty for an overhaul.

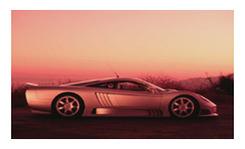

Well, now there is a domestic alternative. Or at least there is supposed to be one next summer, once Steve Saleen starts U.S. deliveries of the Saleen S7. The pretax base price is $375,000, Saleen says, and any of the 74 Ford dealers already certified to sell from Saleen's catalog of hopped-up Mustangs, blown Explorers, and related speed parts will accept the check.

Best of all, the S7 isn't stuffed with titanium overhead electromagnetic thingamajigs. The chassis construction is primarily of tube steel and aluminum sheet, the mid-mounted engine is a 550-hp pushrod Ford small-block V-8 punched and stroked out to 427 cubes (7.0 liters), and you can pump the tires with pure L.A. smog if you like.

The S7 is Steve Saleen's first attempt to match reality with his long-standing assertion that Saleen, Inc., of Irvine, California, is a legitimate automaker, not just one of the hordes of aftermarket tuners specializing in Ford products. He claims the S7 went from sketches to a working vehicle in only 18 months, proof that the 17-year-old company has the engineering beans to do its own car.

Still, he did have some help. The shape of the S7's carbon-fiber-reinforced resin body leaped from the sketch pad of a young Oregon-based independent designer named Phil Frank. Whether intentional or not, the S7's styling owes much to the McLaren F1, from the upwardly rotating doors to the rooftop induction scoop to the four round taillights joined by a narrow black grille of horizontal slats. The S7's posterior, pulled out to house bulky longitudinal street mufflers that actually serve as part of the crash structure, is reminiscent of the later McLaren GTRs configured with stretched bodywork for the Mulsanne. Saleen's trademark fish gills, however, are all his own.

"We decided that it could only be a supercar if it had 60 or more vents," Saleen explains. "This one has 64."

For chassis and suspension work, Saleen turned to England's Ray Mallock, Ltd. The Mallock name is synonymous with a series of front-engined club racers Arthur Mallock built in the late 1960s. In addition to supplying engineering services to fledgling carmakers, Mallock's son, Ray, now fields factory rally and touring-car teams for Nissan, Opel, and Vauxhall.

Mallock developed the S7's bird cage of painted steel tubes with aluminum honeycomb sheets that are riveted on for reinforcement. They form the floor, the fire wall, and the front crash box. Mallock also devised the suspension of steel tubes that are the independent upper and lower control arms. They bolt onto the chassis through aluminum billet plates that are designed to shear on impact to isolate the frame from crash energy. At the other end, the control arms grasp aluminum hub carriers. All four discs -- 15-inch front, 14-inch rear -- are pinched by unboosted six-pot aluminum Brembo calipers.

Mallock took scale models of the S7 to Scotland and the University of Glasgow's wind tunnel to work on underbody aerodynamics, operating on the theory that "what goes on underneath is more important than what goes on up top." He insists the S7's sculpted undertray helps generate downforce equal to the car's weight of 2750 pounds at 160 mph. That means it could run across a ceiling at that speed. Fortunately for him, no insurance company will underwrite a car magazine willing to test that assertion.

Mounted just inches behind the seats is the dry-sump 7.0-liter V-8. Ford casts the aluminum block and heads specifically for Saleen in molds similar to those used for its NASCAR engines. A Ford supplier does the machining on the castings, which includes overboring the cylinders 0.020 inch and porting the heads. Saleen builds up the engine and adds his own unique accessory drive that includes a novel side-mounted water pump. The engine and the chassis will be mated with the body at Saleen's shop in Irvine.