Your 1992 Toyota pickup truck uses a variable-resistor throttle position sensor (TPS) to inform the computer of the exact position of the throttle plate inside the throttle body. The computer uses this and other sensors' data to adjust the air/fuel mixture for better engine performance. Since several sensors work in conjunction, you need to verify your throttle sensor has actually failed. Troubleshoot the TPS yourself at home. Save time and money and avoid replacing unnecessary components in your Toyota pickup.

Open the hood of your 1992 Toyota pickup and locate the TPS. Follow the air cleaner assembly, which houses the air filter, toward the top and center of the engine. This assembly connects to the throttle body on that end. The throttle body has four thin hoses connected on top and under the hoses, on one side of the throttle body, you will see the TP sensor, a small, black electrical component with a four wire electrical connector attached to it.

Remove the air cleaner assembly using a Phillips screwdriver.

Unplug the TPS electrical connector and make sure the four electrical pins on the sensor are straight and not bent or damaged.

Ask an assistant to depress slowly the accelerator pedal as you watch the throttle body. On one side of the throttle body, you will see the mechanism that activates the throttle round plate inside the body as your assistant depresses the accelerator pedal. This mechanism has a lever that hits a stop screw when the mechanism is resting or the pedal is not depressed.

Make sure the throttle plate is fully closed (accelerator pedal not depressed).

Insert a 0.0224-inch thick feeler gauge (0.57 mm) between the throttle mechanism lever and the stop screw, if you have a 22R-E engine. Use a 0.020-inch (0.50 mm) feeler gauge on the 3VZ-E and 1FZ-FE engines. Use a 0.022-inch (0.57 mm) feeler gauge on the 2RZ-FE and 3RZ-FE engines. Use a 0.013-inch (0.32 mm) on the 5VZ-FE engine and a 0.0303-inch (0.77 mm) feeler gauge on the 3F-E engine.

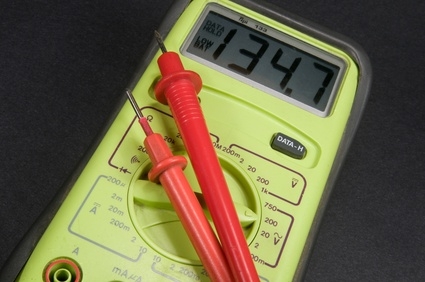

Get the ohmmeter out of your toolbox and set it to the lowest range on the Ohms scale or the continuity setting, if it has one.

Turn on your ohmmeter and touch the bottom and next to the bottom electrical pins on the sensor with your two meter probes. The readout on your ohmmeter should register some resistance or produce an audible beeping sound, if it is equipped with a continuity checker. If the sensor does not register any resistance value or continuity, replace it.

Replace the feeler gauge with a 0.0335-inch (0.85 mm) feeler gauge between the throttle mechanism lever and the stop screw, if you have a 22R-E engine. Use a 0.031-inch (0.80 mm) feeler gauge on the 3VZ-E and 1FZ-FE engines. Use a 0.029-inch (0.74 mm) feeler gauge on the 2RZ-FE and 3RZ-FE engines. Use a 0.021-inch (0.54 mm) on the 5VZ-FE engine and a 0.0429-inch (1.09 mm) feeler gauge on the 3F-E engine.

Touch the bottom and next to the bottom electrical pins on the sensor with your two meter probes. The readout on your ohmmeter should not register any resistance value or produce a beeping sound, if it is equipped with a continuity checker. If the sensor registers resistance or continuity, replace it.

Turn off your ohmmeter, plug in the TPS electrical connector, replace the air cleaner assembly using the Phillips screwdriver and close the hood.