Engines are subject to wear and stress from day-to-day city driving, overheating and overloading. Contaminates that enter the engine through the air intake or through the engine oil system cause wear in the cylinders and on the piston surfaces. As cylinder wear increases, engine efficiency decreases to the point that the cylinders must be bored and the pistons replaced to return the engine to peak operating efficiency.

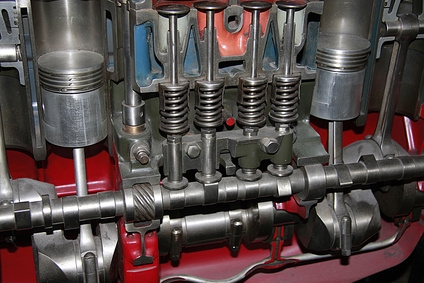

Understanding the reasons for boring an engine begin with understanding the work that piston rings accomplish. The top piston ring seals the gap between the piston and the cylinder wall during the compression stroke. The second ring stops oil from moving up the cylinder wall and interfering with engine compression. If the rings are not able to seal against the cylinder wall, compression gasses blow by the rings and contaminate the engine oil.

As the pistons move up and down in the engine, the rings wear away the upper cylinder wall, causing the cylinder to be wider at the top than at the bottom. Taper at the bottom of the cylinder is caused by contaminated oil. As contaminated oil moves up the cylinder wall, it causes wear between the cylinder and the piston. Cylinder taper reduces the ring's ability to seal the compression gasses in the compression chamber and reduces the rings ability to keep oil from getting into the compression chamber.

Cylinders become out of round by thermal distortions caused by overheating or overloading of an engine. Distortion is also caused by improper torquing when the heads are installed on the engine, or by differences in the ability of different metals to withstand thermal stresses. An out-of-round cylinder causes the rings to change shape in an effort to seal the combustion chamber. Over time, the the cylinder distortion may cause the rings to break

Scoring of the cylinder walls is caused by either contaminates between the cylinder wall and the piston, a lack of lubrication, or a combination of the two. Contaminates can come from unburned fuel deposits or contaminates in the engine oil. Scoring gouges the cylinder walls allowing combustion gasses to escape into the crankcase and further contaminate the engine oil. Oil is also allowed to move up past the rings into the combustion chamber causing the engine to burn oil.

High-performance engine builders bore cylinders to obtain larger engine displacement increasing capacity and horsepower. Precision cylinder boring and installation of custom-sized pistons enhances compression and engine efficiency. Precision boring allows the engine builder to square up the cylinders so the connecting rods align precisely with the crankshaft journals reducing misalignment of engine parts and increasing engine efficiency. Precision engine boring is usually done in conjunction with precision machining of the engine heads.