Before you scream "Danger, danger, Will Robinson!" you should know this is one of the simplest repairs you can do. It's important to have a strong alternator that functions properly, especially for low-speed 'wheeling. It's also important if your battery is weak or if you've added extra lights or other electrical accessories.

The favorite alternator of many enthusiasts is either the inexpensive GM Delco 10si or the 12si with a built-in regulator, introduced in the early '70s. (The "si" means systems integrated.) It's popular because it's user-friendly, a universal fit, readily available, and a bolt-in deal.

You can swap the GM alternator into an early GM 4x4 or an early non-GM 4x4. Yep, it works great in a non-GM truck. And it doesn't matter if you currently run an externally regulated alternator-the 10si and the 12si bolt right onto the bracketry in early GM 4x4s and can be mounted onto most non-GM 4x4s. Unfortunately, owners of late-model 4x4s really can't do this conversion. One of the biggest fans of this conversion is Mark Hamilton, president of M.A.D. Enterprises. He has a GM alternator in his Ford and swears by its reliability.

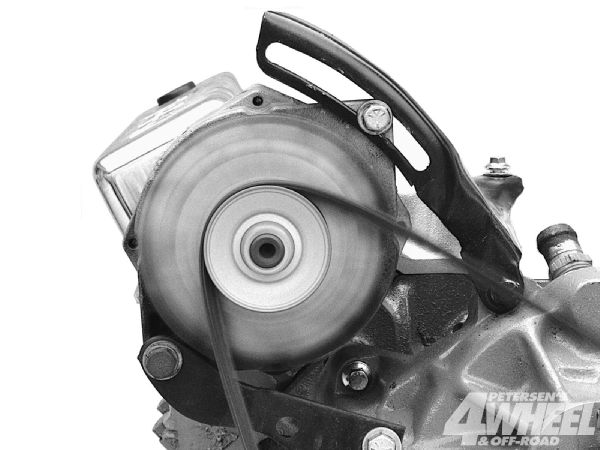

We got our hands on a 10si model and turned to Hamilton to show us just how simple the rebuild is.

This Is a Test

How can you tell if your alternator is working properly? Get an accurate DC voltmeter with a range from 0 to 18 or 0 to 20 volts. Hook the voltmeter across the battery and let the engine run at highway-cruise rpm, about 2,500 rpm. If the voltmeter reads between 14.0 and 14.5, it's normal; 12.5 is a no-charge condition, while above 15 indicates an overcharge caused by a bad regulator.

Part by Number

The part numbers for the AC Delco parts are different depending on whether you purchase them at an auto parts store or an authorized GM or AC Delco dealer. Here are the numbers for both.

Easy Conversion News

M.A.D. Enterprises makes it easy to convert from a generator system or external voltage regulator system to a 10si or 12si with its High Output alternator wiring kit for the GM Delco alternator with a built-in voltage regulator. Parts and wiring diagrams are included in the well-detailed instructions for both warning-light and meter-at-the-dash systems.

Converting to a GM alternator (sometimes called a Delcotron si) with a built-in regulator is easy and inexpensive. First on your shopping list should be the alternator-a 63-amp model should have enough output if your truck is stock; more than 63 is better if you have an electric radiator fan in your air-conditioned truck and spend time idling in traffic, have dual batteries, or have powerful off-road driving lights. You may be able to find the unit used.

PhotosView Slideshow