You’re looking for more power out of your Jeep and your buddy suggests the tried- and-true engine swap to transplant V-8 power. He goads you on, telling you how it’s an easy weekend swap and maybe $1,000 in parts and cold beverages. So, you pull your trusty, but tired, inline-six engine out and bolt that V-8 in over a weekend. But six weeks later, you’re still riding the bus and bumming rides from friends as your Jeep sits idle under your carport.

Truth be told, proper engine swaps require good planning, plus more time and money than almost everyone expects. However, dropping in modern fuel-injected V-8 power in your Jeep, when done well, can inspire a huge grin in the end. We recently had the chance to follow along as Lamb Fab, a custom shop in Gilbert, Arizona, swapped a 4.8L GM V-8 into an ’87 Jeep Wrangler.

Here is the donor engine. It was salvaged from a very low-mileage ’01 Chevy Silverado. The 4.8L V-8 is the smaller cousin of the very popular 5.3L engine found in so many GM pickups and SUVs. Both engines share the same block, and it’s difficult to determine which is which from an external viewpoint. So, many details of this YJ swap can also apply if you’re dropping in a 5.3L or 6.0L Generation III truck engine.

Here is the donor engine. It was salvaged from a very low-mileage ’01 Chevy Silverado. The 4.8L V-8 is the smaller cousin of the very popular 5.3L engine found in so many GM pickups and SUVs. Both engines share the same block, and it’s difficult to determine which is which from an external viewpoint. So, many details of this YJ swap can also apply if you’re dropping in a 5.3L or 6.0L Generation III truck engine.

The shop started with a very low mileage 4.8L salvaged from a ’01 Silverado pickup. The Vortec LR4 engine is a small-block engine used from ’99 to ’06. It’s the smallest Generation III truck engine and runs a slightly shorter stroke than the very common 5.3L engine. The smaller brother has the same cross-bolted mains and high-flow aluminum heads. The 5.3L version offers some horsepower advantage, while the 4.8L offers a small edge in fuel economy.

For this swap, only the complete engine was purchased because the Jeep already had an AX15 manual transmission that was going to be retained. Advance Adapters offers a fairly comprehensive set of swap parts to do this conversion, and many of those parts were used for this swap.

Much of the swap hardware came from Advance Adapters. They’ve long made swaps such as this much easier by providing the benefit of their research. Plus the company gains the experiences of engine swappers who use its parts and provide feedback on what works and what doesn’t.

Much of the swap hardware came from Advance Adapters. They’ve long made swaps such as this much easier by providing the benefit of their research. Plus the company gains the experiences of engine swappers who use its parts and provide feedback on what works and what doesn’t.

After it was complete, the Wrangler ran great and has proven to be very reliable and a blast to drive. There’s a good bet that after pulling the stock inline-six and replacing it with the aluminum head, cast-iron block V-8, the final weight of the Wrangler was a few pounds lighter. The fit under the hood is a comfortable one and the owner was quite impressed with the newfound power and the torque of the bigger engine. Follow along and we’ll show you many of the details that went into completing the project.

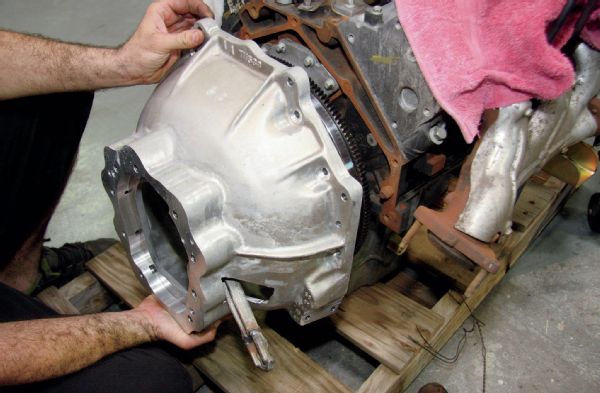

The donor engine was originally connected to an automatic transmission. The flexplate was removed, and a pressure plate and clutch assembly from the Advance Adapters kit was aligned and bolted to the rear of the engine.

The donor engine was originally connected to an automatic transmission. The flexplate was removed, and a pressure plate and clutch assembly from the Advance Adapters kit was aligned and bolted to the rear of the engine.

Here’s the Advance Adapters conversion bellhousing to bolt a GM LS engine to an AX15 manual transmission. It came complete with the throwout bearing and clutch fork to mate the factory Jeep slave cylinder. With manual transmission swaps, you’re dealing with mating clutch parts, while auto transmissions may require added fluid cooling accommodations, and possible computer control.

Here’s the Advance Adapters conversion bellhousing to bolt a GM LS engine to an AX15 manual transmission. It came complete with the throwout bearing and clutch fork to mate the factory Jeep slave cylinder. With manual transmission swaps, you’re dealing with mating clutch parts, while auto transmissions may require added fluid cooling accommodations, and possible computer control.

Lamb Fab made quick work of extracting the stock engine from the Wrangler, leaving a gaping hole ready for a new engine. The stock engine mounts were cut from the frame and the framerails ground clean to accept new mounts.

Lamb Fab made quick work of extracting the stock engine from the Wrangler, leaving a gaping hole ready for a new engine. The stock engine mounts were cut from the frame and the framerails ground clean to accept new mounts.

With the V-8 mocked into place, mounting position could be determined and preparation made to install new engine mounts. Time spent here is valuable to the final results. Engine placement can affect hood, radiator, and firewall clearance. Position may also affect drivetrain angle and ultimately driveshaft angles and clearances.

With the V-8 mocked into place, mounting position could be determined and preparation made to install new engine mounts. Time spent here is valuable to the final results. Engine placement can affect hood, radiator, and firewall clearance. Position may also affect drivetrain angle and ultimately driveshaft angles and clearances.

Lamb Fab made quick work of extracting the stock engine from the Wrangler, leaving a gaping hole ready for a new engine. The stock engine mounts were cut from the frame and the framerails ground clean to accept new mounts.

Lamb Fab made quick work of extracting the stock engine from the Wrangler, leaving a gaping hole ready for a new engine. The stock engine mounts were cut from the frame and the framerails ground clean to accept new mounts.

Advance Adapters universal engine mounts were used and each outer mount welded to a framerail. Multiple holes are provided to allow for some movement within the engine bay. Given the frame spacing on the Wrangler, a hole on one mount had to be slotted to get the halves to line up so a bolt could be installed.

Advance Adapters universal engine mounts were used and each outer mount welded to a framerail. Multiple holes are provided to allow for some movement within the engine bay. Given the frame spacing on the Wrangler, a hole on one mount had to be slotted to get the halves to line up so a bolt could be installed.

When setting the engine position in the Jeep, one thing to watch for is steering shaft clearance. In the end, the engine was placed approximately 1-inch off-center towards the passenger side to allow the engine to clear the steering shaft running to the steering box. Fortunately, for this swap, the Jeep power steering hoses bolted right up to the GM pump without any modifications at all. This doesn’t happen often.

When setting the engine position in the Jeep, one thing to watch for is steering shaft clearance. In the end, the engine was placed approximately 1-inch off-center towards the passenger side to allow the engine to clear the steering shaft running to the steering box. Fortunately, for this swap, the Jeep power steering hoses bolted right up to the GM pump without any modifications at all. This doesn’t happen often.

An Advance Adapters aluminum radiator was used that was designed specifically for this conversion, making it an easy bolt-in affair. The stock radiator is not up to the task of cooling the larger V-8 engine, plus all the outlets on this radiator have been placed to work with the GM LS engines.

An Advance Adapters aluminum radiator was used that was designed specifically for this conversion, making it an easy bolt-in affair. The stock radiator is not up to the task of cooling the larger V-8 engine, plus all the outlets on this radiator have been placed to work with the GM LS engines.

Near the radiator cap, the top hose was routed to the factory overflow bottle. The lower hose is the steam line that connects to the throttle body on these engines. The steam line is important on GM LS engines and is used to purge air from the engine coolant system and to route coolant to the throttle body.

Near the radiator cap, the top hose was routed to the factory overflow bottle. The lower hose is the steam line that connects to the throttle body on these engines. The steam line is important on GM LS engines and is used to purge air from the engine coolant system and to route coolant to the throttle body.

The upper hose is one used on a 5.3L Chevy truck that was cut and shortened in the middle. The two pieces were reliably and cleanly joined using a heat-shrink hose clamp. An electric fan from a Ford Taurus application was used and fits the surface area of the radiator well.

The upper hose is one used on a 5.3L Chevy truck that was cut and shortened in the middle. The two pieces were reliably and cleanly joined using a heat-shrink hose clamp. An electric fan from a Ford Taurus application was used and fits the surface area of the radiator well.

The lower radiator hose was found on the shelf at the local parts store. The heater outlets on the new engine were easily plumbed to the factory Jeep heater using generic heater hose.

The lower radiator hose was found on the shelf at the local parts store. The heater outlets on the new engine were easily plumbed to the factory Jeep heater using generic heater hose.

An inline fuel filter and Walbro inline electric fuel pump (45 gph, approxmently 75 psi) were installed along the driver side framerail to pump fuel from the stock gas tank to the fuel rails on the new engine. The pre-filter application is from a ’84 fuel-injected Corvette.

An inline fuel filter and Walbro inline electric fuel pump (45 gph, approxmently 75 psi) were installed along the driver side framerail to pump fuel from the stock gas tank to the fuel rails on the new engine. The pre-filter application is from a ’84 fuel-injected Corvette.

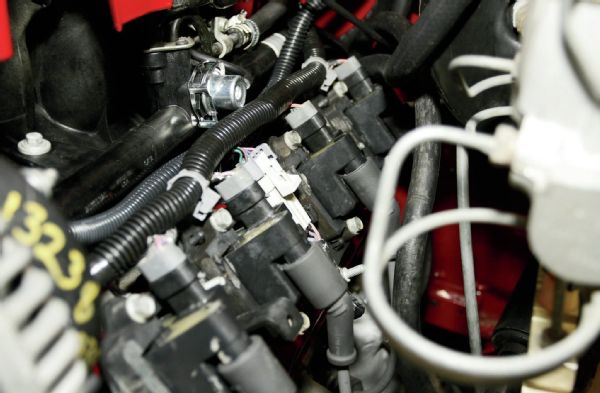

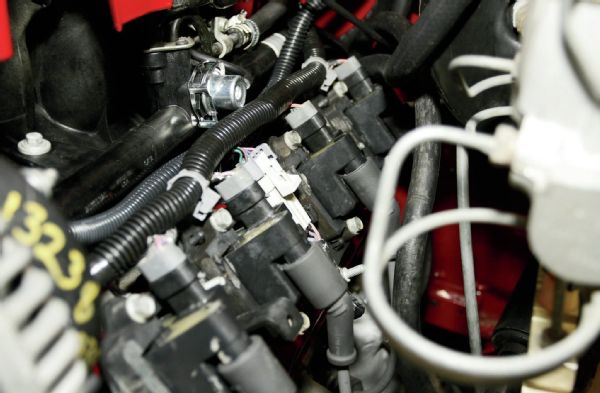

Since junkyard engines can sit idle for long periods of time, the fuel may turn to varnish and clog up the fuel rails. Lamb Fab recommends sending the injectors to a qualified shop to have them cleaned, then leak-down and flow tested. If one injector leaks down and fills a cylinder with fuel, the result can be a bent or broken piston rod.

Since junkyard engines can sit idle for long periods of time, the fuel may turn to varnish and clog up the fuel rails. Lamb Fab recommends sending the injectors to a qualified shop to have them cleaned, then leak-down and flow tested. If one injector leaks down and fills a cylinder with fuel, the result can be a bent or broken piston rod.

A local muffler shop was called upon to install a new exhaust system. The factory V-8 cast-iron exhaust manifolds were retained as they hug the block well. The driver side pipe was run slightly forward and down under the engine oil pan. The two head pipes meet at a Y-pipe on the passenger side, and a single 21⁄2-inch exhaust runs to a single Flowmaster 50 Series muffler and out the tail of the Wrangler.

A local muffler shop was called upon to install a new exhaust system. The factory V-8 cast-iron exhaust manifolds were retained as they hug the block well. The driver side pipe was run slightly forward and down under the engine oil pan. The two head pipes meet at a Y-pipe on the passenger side, and a single 21⁄2-inch exhaust runs to a single Flowmaster 50 Series muffler and out the tail of the Wrangler.

A compact Powermaster XS Torque starter was used for the swap. A corner of the starter flange had to be ground down some to clear the bellhousing. Wiring is straight-forward and the factory Jeep connections were all used on the new starter.

A compact Powermaster XS Torque starter was used for the swap. A corner of the starter flange had to be ground down some to clear the bellhousing. Wiring is straight-forward and the factory Jeep connections were all used on the new starter.

A custom swap harness was sourced from a local speed shop that specializes in swap harnesses. The engine control module (ECM) was also reprogrammed and set up to work with the manual transmission. LS harness work is now available from a variety of experienced sources, should you not have the time or inclination to tackle the engine control electrical yourself.

A custom swap harness was sourced from a local speed shop that specializes in swap harnesses. The engine control module (ECM) was also reprogrammed and set up to work with the manual transmission. LS harness work is now available from a variety of experienced sources, should you not have the time or inclination to tackle the engine control electrical yourself.

The ECM was mounted on the passenger side inner fender, just forward of the firewall. The LS engine controllers are designed to survive the heat and vibration under the hood, so mounting here is acceptable.

The ECM was mounted on the passenger side inner fender, just forward of the firewall. The LS engine controllers are designed to survive the heat and vibration under the hood, so mounting here is acceptable.

The ECM has the ability to control an electric fan in the factory application. However, the fan control signal cannot supply enough current to drive the input to the Taurus fan. Lamb Fab instead wired the ECM output to the control terminal of a continuous duty starter relay, whose output was then used to power the Taurus fan.

The ECM has the ability to control an electric fan in the factory application. However, the fan control signal cannot supply enough current to drive the input to the Taurus fan. Lamb Fab instead wired the ECM output to the control terminal of a continuous duty starter relay, whose output was then used to power the Taurus fan.

The factory GM alternator on the V-8 was retained and needed to be wired into the Jeep electrical system. The exciter wire for the alternator was built into the new harness. The main charge wire from the alternator was routed to the battery positive post, with a Maxi-Fuse used inline.

The factory GM alternator on the V-8 was retained and needed to be wired into the Jeep electrical system. The exciter wire for the alternator was built into the new harness. The main charge wire from the alternator was routed to the battery positive post, with a Maxi-Fuse used inline.

The air intake was put together from generic air intake fittings that are readily available in multiple sizes. A large Spectre open element filter was used and the factory GM manifold absolute pressure (MAP) sensor was used just behind the filter element. A simple fabricated metal bracket supports the filter and intake off the engine.

The air intake was put together from generic air intake fittings that are readily available in multiple sizes. A large Spectre open element filter was used and the factory GM manifold absolute pressure (MAP) sensor was used just behind the filter element. A simple fabricated metal bracket supports the filter and intake off the engine.

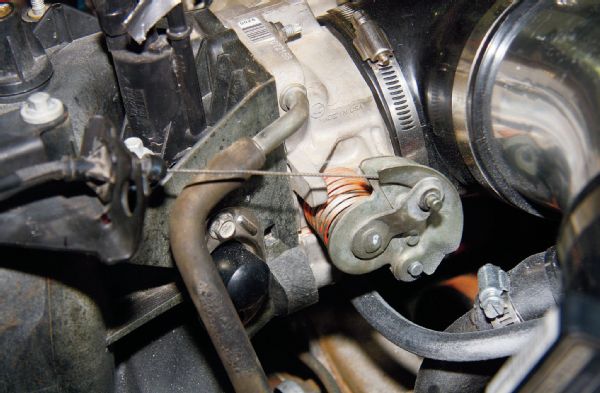

Lamb Fab used an OEM throttle cable from a 4.3L Chevy S-10 truck with only minor modifications needed to ensure full throttle travel. This was the final piece of the puzzle, and the engine was ready to be fired up. This accounting should give you a good idea of the details involved to complete an engine swap such as this.

Lamb Fab used an OEM throttle cable from a 4.3L Chevy S-10 truck with only minor modifications needed to ensure full throttle travel. This was the final piece of the puzzle, and the engine was ready to be fired up. This accounting should give you a good idea of the details involved to complete an engine swap such as this.