Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

As time moves on, technology gets...well, more technical. In the good old days when you wanted to shift the gears in your truck all you had to do was push in the clutch, pull a lever, and let out the clutch. But eventually that seemed too difficult so someone invented the automatic transmission filled with fluid, clutches, bands, valves, pumps, and planetary gearsets all designed to shift gears more smoothly and quicker than a manual. And then when that seemed too simple they added a computer to help it work even better. Don't get us wrong, automatics are great when they are working right, but they can also be a giant headache when they act up, especially when you're buried in the mud miles from home.

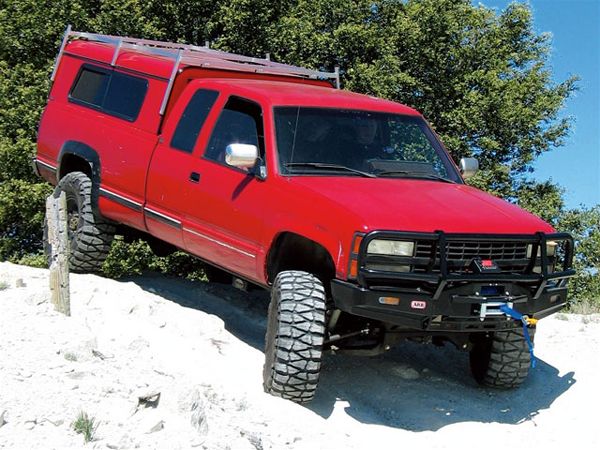

For example, we've been working on a '91 3/4-ton Chevy truck that we've christened the Red Sled (it turns like a toboggan) with the goal of testing some hard-core Independent Front Suspension (IFS) components. We got this truck for a song because it was missing an engine, but it's been an uphill project from the start. To make a long story short, we stuffed an engine in, lifted the truck, upgraded the steering, and took it wheeling. Then the electronic automatic transmission died, so we rebuilt the tranny and it died again. At this point we were really considering installing a manual transmission, but we already had that swap in motion for another project, so we decided to explore the options of keeping the auto, but making it better.

Since this truck is a work, camping, and wheeling truck it needs a reliable gearbox, a way to keep track of and control the heat the tranny is making (heat kills automatics), and better low-range gearing to help move this 7,000+ pound behemoth off road. The Sled came from the factory with a 4L80E automatic and an NV241 transfer case. The 4L80 is similar in strength to the venerable TH400 but with the added benefit of an overdrive Fourth gear-both great aspects-but it is also computer controlled, which 99 percent of the time isn't a problem. However, it can create additional dilemmas when changing tire size and gearing, or if you wanted to swap this transmission into another vehicle. To get the most of our 4L80 we headed to Off Road Unlimited where we pulled the 4L80E out and then took it to B&M Racing for a rebuild and an external controller, which would allow us to have greater control and diagnostic management of the trans.

Since the NV241 only has a 2.72:1 low range we decided an upgrade had to be made in the transfer-case arena. Our choice was a STAK three-speed Monster Box transfer case, which replaced our strong chaindrive 241 with massive geardriven internals, both a 3.05:1 and 5.44:1 low range, and the ability to run low range from either front or rear output individually. What we ended up with is a greater range of gearing off road, and a more user-friendly transmission management system on road. Plus the ability to get our Red Sled back on the trail, and once there, really test the strengths of an independent front suspension. Stay tuned to find out what happens when big-block power, super-low gearing, extremely obese curb weight, and big tires are applied to an independent front suspension in the rocks.

For a speed-sensor signal you have a few options. Some automatics have a transmission output speed sensor (TOSS) and others rely on an output speed sensor (OSS) in the transfer case. We had our transmission rebuilt and made sure it had a TOSS installed, and we also installed this Advance Adapters' speed sensor onto the input of the STAK case. 3 The AA piece has the pickup threaded into the transmission-to-transfer-case adapter, so all speed-sensor signals are recorded prior to transfer-case low-range gearing. Thus the tranny always shifts like it is in two-wheel drive. At first we assumed we would need the TOSS to run the Compushift and the AA unit for the factory speedometer, but we found that the Compushift has a reproduced TOSS signal that can be wired into the factory harness to control the speedo.

Here is the new view from the cockpit. There is a B&M temp gauge on the dash keeping track of the 4L80E, the new three sticks controlling the STAK coming up through the floor. The left shifter is for the front output. Push it forward and you have low range, middle is neutral, and back is high. The middle shifter chooses between 5:1 or 3:1 low range, and the right shifter engages the rear output. Unfortunately we got a little excited when cutting the hole for the shifters and had to then go back in and plate over the giant opening we cut. Finally we added a new triple-shifter boot from JB Custom Fab that greatly eliminates heat and noise intrusion to the cab. Also on the floor there is the Compushift display programmer within easy reach and in sight to keep track of the data arriving from the fresh tranny. The red knob on the dash below the gauge is the front axle Posi-Lok activator; see the complete install of that elsewhere in this issue.

PhotosView Slideshow

PhotosView Slideshow