Christian Hazel

Brand Manager, Four Wheeler

Photographers:

Courtesy Golen Engine Service

Christian Hazel

Brand Manager, Four Wheeler

Photographers:

Courtesy Golen Engine Service

The Insane Inline, Part 1

The Insane Inline, Part 2

The Insane Inline, Part 3

That's right; we're dusting off our trusty '99 XJ, Project JR. Not that it ever lay dormant. It's been dutifully serving as Hazel's outlet for pent-up aggression and as a daily driver, all too frequently making the 250-mile round-trip commute to the dark tower that is the Primedia building. Although still reliable, with almost 150,000 miles on the clock, the stock 4.0L has outstayed its welcome. It's still fairly tight, but we've noticed there's a little more piston knock upon cold start-up, the top end is a little lazy, and the fuel mileage is slowly but steadily dropping into the low 10s. Time for a new engine.

In this installment we'll walk you through some of the finer points of our new Golen Engine Service 4.6L stroker as its assembled. In Part II we'll strap it to Golen's engine dyno to break it in and check the power levels, then we'll walk you through an inline engine swap. Finally, in Part III we'll address all the stuff that needs addressing to get the larger engine to run right with our 4.0L computer, fuel system, and so on. We'll strap it to a chassis dyno for some rear-wheel-power numbers, then install a nitrous system and take it to the dragstrip to see how close we can come to blowing the doors off some '80s-era Mustang GTs.

Golen likes to shoot for a 0.040-inch quench height for more power and to prevent pinging and knocking. After a thorough cleaning, the inspected 4.0L block is decked to achieve a zero deck height for use with the Fel-Pro head gasket's 0.040-inch compressed thickness and to leave a mirror finish for head-gasket sealing. In our case, 0.020 inch was removed to achieve the proper quench before the boring process began.

Golen likes to shoot for a 0.040-inch quench height for more power and to prevent pinging and knocking. After a thorough cleaning, the inspected 4.0L block is decked to achieve a zero deck height for use with the Fel-Pro head gasket's 0.040-inch compressed thickness and to leave a mirror finish for head-gasket sealing. In our case, 0.020 inch was removed to achieve the proper quench before the boring process began.

WHY CHOOSE GOLEN?

When it came time to pick an engine to put in our project XJ, we had some pretty demanding criteria. Not just any engine would do since this vehicle is the ultimate jack-of-all-trades. In addition to spinning at 3,200 rpm for up to two hours at a stretch during commuting duties, our new engine will have to survive the harsh off-road environment of desert prerunning, sand dunes, intense heat, the occasional drag race, and probably a lot of nitrous. Hazel is a die-hard power junkie. We knew we wanted a stroker for the increase in power, but we also needed it to be ball-peen-hammer tough and reliable.

Golen Engine Service has its roots firmly planted in the circle track and drag-race industry, where its reputation for building top-quality race engines with extremely tight tolerances is well known. Since branching out into the street-rod and Jeep market, it has built well over 100 4.6L stroker engines, but unlike your generic mass-volume engine rebuilder, Golen blueprints the engines one at a time to make sure everything is bang-on right. We're betting with the right care our new stroker can see 250,000 miles with ease.

The block is then fitted with a torque plate (not shown) and bored close to 0.030-inch overbore on Golen's Sunnen CV-616 machine. Once the Speed-Pro hypereutectic pistons are measured, the block is finish-honed to take the bores out a full 0.030 over and match any minute variations in piston diameter. Golen's honing is so precise there's less than 0.0001 inch of taper from the top of the cylinder wall to the bottom.

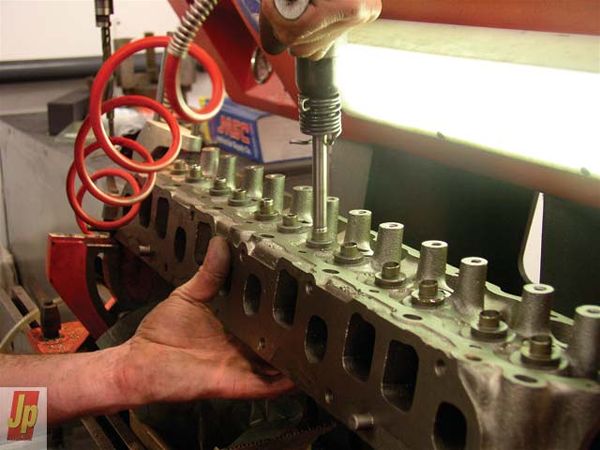

Anyone who knows engines knows you make your power in the cylinder heads. Golen uses the '91-'95 H.O. heads since they're the best-flowing to start with, then completely rebuilds and massages them for long life and better flow. Machinist George Connoly begins by cutting the heads for new valve guides on Golen's Serdi valve machine.

The Serdi features an alignment fixture that indexes off the valve guides to ensure the valve job is cut square and provides the utmost in sealing, so Connoly takes great care when driving in the new guides.

With the new guides in place, the head is cut with a three-angle performance valve job. The valve seats are cut and blended for larger 1.94-inch intake and 1.50-inch exhaust valves. This increases the airflow through the port and allows the stroker to breathe much better than with the comparatively choked stock heads.

In addition to the performance valve job, Golen also back-cuts the valves to improve the flow a bit more. Here, the valve is installed on its seat, then a vacuum test is performed to ensure the valve seat is cut properly. A vacuum leak means the valve doesn't seal and the valve job doesn't pass muster. Ours all topped out well above acceptable levels.

The cylinder head is machined to provide a dead-straight gasket surface and to bring the combustion chambers to 62 cc. With the blended bowls, high-performance valve job, and new valve guides, the head will flow at least 155 cc and provide years of dependable service.

To achieve the correct 1.700-inch installed spring height for the Comp Cams valvesprings, the valvespring pockets in the cylinder heads are cut accordingly. Some shops will simply install hi-po springs without performing this step, but for these Jeep heads it's a crucial part of getting the right spring tension. Too much and you'll eat cam lobes. Too little and you'll get valve float at high rpm.

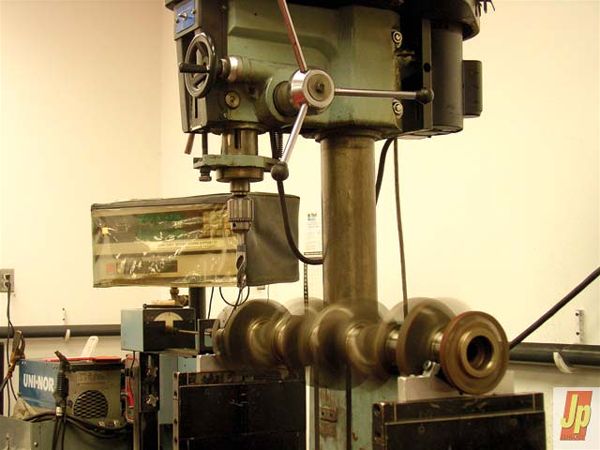

The entire rotating assembly is balanced to within 0.5 grams. That's pretty impressive. The pistons and 4.2L rods are weighed, then the crank is sent for a ride on the balancer.

The beauty of the Jeep six is that, unlike some high-end strokers, there's no need for expensive Mallory metal to bring the rotating assembly into balance. Just a little material is removed where necessary from the crank, and that's all that is needed.

Here, Chad Golen taps the Speed-Pro pistons home. The hypereutectic pistons will stand up to a decent-size shot of nitrous or supercharging. Once the machining was finished, Dan Eddins assembled the rest of the engine, including the Comp Cams bumpstick and lifters, and got our engine ready for the dyno. Tune in next month to see what it belts out and to follow as we install it into Project JR.

The Insane Inline, Part 1

The Insane Inline, Part 2

The Insane Inline, Part 3