Jerrod Jones

Former Editor, Off Road

Jerrod Jones

Former Editor, Off Road

When you’re looking for just a couple inches of lift beyond what your linked Jeep currently has, you can often get away with minimal modifications to achieve your goal. Steering, track bar, control-arm angles, along with brake-line lengths, usually do not have to be addressed. Even your existing shocks can sometimes work with a one or two inch change in ride height. Whether you’re going up to 2 inches of lift or heading from 7 to 9 inches of lift, suspension and alignment adjustments should be minimal (but always mandatory when changing ride height).

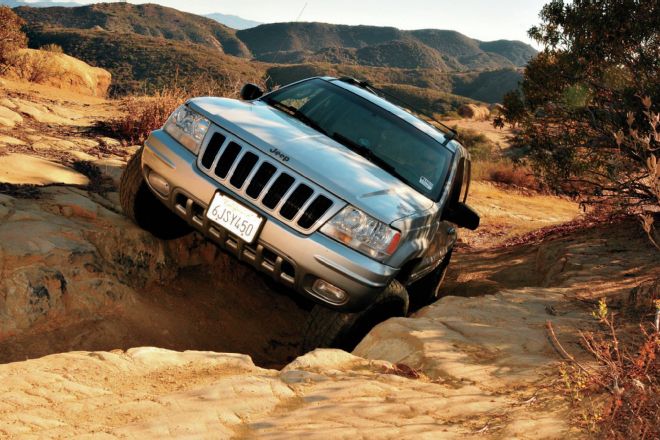

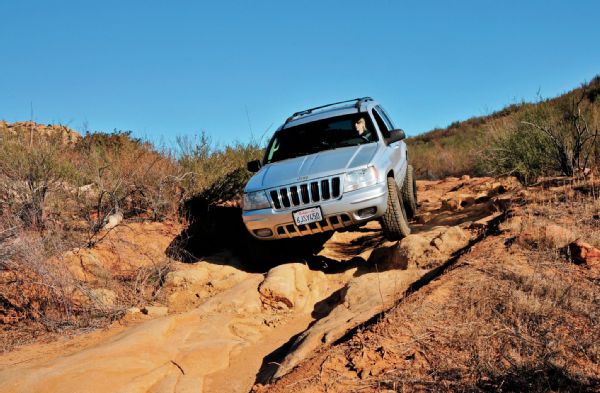

To achieve a couple inches of lift, you have the option of either replacing your existing springs or adding coil spring spacers. We all know new coils perform better, but that doesn’t mean they’re necessarily better for your situation. Both new springs and spacers have their benefits, and we’ll try to cover the pros and cons of why either may be an option for you. We installed both spring spacers and replacement coil springs on an ’03 Grand Cherokee WJ to get a feel for how both affected this Jeep and its performance.

Coil spacers, leveling kits, leveling spacers, spring blocks—whatever you want to call them, they all add an effective one, two, or three inches of ride height to your coil-sprung suspension. While these Daystar spacers are made from polyurethane (manufactured in the USA, we might add), spacers can also be manufactured out of a harder plastic, steel, iron, or aluminum.

Coil spacers, leveling kits, leveling spacers, spring blocks—whatever you want to call them, they all add an effective one, two, or three inches of ride height to your coil-sprung suspension. While these Daystar spacers are made from polyurethane (manufactured in the USA, we might add), spacers can also be manufactured out of a harder plastic, steel, iron, or aluminum.

Conclusive spoiler alert: We love the new replacement springs. And we don’t think anyone—including spacer manufacturers—will argue the performance benefits of replacement coils. However, we may have been loading the deck a bit by using Old Man Emu (OME) coils. Their coils are known to give an excellent ride, and this application was no different. Did the spacers do the job? You bet, and they didn’t change the factory spring rate.

If you’re looking to get your Jeep up a couple inches as quickly and cheaply as possible, get some spacers coming. If cost isn’t a factor and you’re looking for better performance than you had, check out a custom coil-spring replacement.

PhotosView SlideshowPros and Cons of Spacers

Pros

Cost effective: Spacers are inexpensive. Some cost more than others, but we don’t know of any spacers that cost over a couple hundred dollars. It’s the cheapest way to lift a coil-sprung Jeep. That being said, don’t get too cheap and use wood spacers or something.

Versatile: They work with any factory or non-factory coil spring, regardless if it’s a heavy-duty coil or a light-duty coil.

No change in spring rate: Spacers do not change the spring rates. It could be argued that in certain applications, a spacer changes the available compressed height and sometimes the angle at which the springs deflect off the spring pads, but if that’s ever the case, the change is minimal and basically unnoticeable. The manufacturer spends millions of dollars testing and engineering the stock coil springs and how they work with the sway bars. Remember to think about that investment when making your decision.

Fixed amount of guaranteed lift: A spacer basically changes the height of the spring pad. A spacer will give a fixed amount of lift that will never change. The coil spring, used in conjunction with a spacer, can change lift height (due to wear or a change in weight), but the spacer will never change height.

Easy to install: A spacer is as easy to install as a coil spring, if not easier.

Cons

No change in spring rate: Sometimes, you want to change the spring rate due to added equipment or you want to improve the ride. A spacer will never improve the ride, and it generally will not change the spring rate.

Potential decrease in travel: You are adding a block in between upper and lower spring pads—a space shared with the coil springs. If you add a 2-inch spacer without somehow adding 2 inches of droop to your suspension (maybe longer shocks and sway bar links), then you’ve effectively reduced your available collapsed length between the spring pads by 2 inches. If your coil comes close to completely collapsed at full compression, then this might limit up travel.

Spacer could fall out: It never happened on this WJ, but we have seen spacers move on vehicles equipped with longer aftermarket shocks. If a spacer becomes dislodged, it can possibly fall out or not allow the coil spring to seat properly. This is a rare occurrence, but remember that you are complicating the system by adding an extra part (the spacer), and more parts often means more things could go wrong.

Spacer Versus Spacer

Not all spacers are the same. It’s fairly simple technology, yes? You’re basically adding lift blocks to your coil springs. However, the material the spacer is made of can make a difference—depending on whom you ask. You have a choice of a metal spacer or some type of plastic-derived spacer. Theoretically, the metal spacer should not change the spring rate or ride quality. Soft plastic/hard rubber spacers like the urethane Daystar units shown in this article may actually soften harsh hits—at least that’s what some owners attest to. Rely on shocks and bumpstops for ride control instead of coil spacers for any cushioning effect.

Pros and Cons of Replacement Coils

Pros

New coils guarantee a fresh spring rate: Even if you replace your coil springs with the exact same ones (only new) you may see a change in spring rate. Springs wear out and sag, and when they do, they can soften up and/or change the ride height.

Customize your spring rate: You can specify your spring rates with custom coils springs. You can order progressive-rate coils, heavy-duty coils, light-duty coils, or get the same spring rate you had before, only in a taller version. But remember to match your coils and sway bars together. That’s why Old Man Emu offers both their light-duty and heavy-duty coil springs with sway bar packages.

Minimal collapsed length change: The compressed distance between the upper and lower spring pads does increase when adding a taller coil, but only by a small amount

Better performance: A coil spring tuned for your vehicle and usage can make driving it a lot more fun. The Old Man Emu coils we used tremendously improved the drivability of this WJ that came from the factory with an unusually soft spring rate and stiffer sway bars to compensate.

Cons

Cost: New coil springs can be expensive. If you have custom coil springs built from scratch, it can cost many hundreds of dollars. You can save a lot of money if you can find a high-quality off-the-shelf coil spring like the OME coils we got.

Potential for incorrect ride height: There is the chance that the coil won’t give the advertised ride height or at least not the one you were expecting and hoping for.

Potential for incorrect spring rate: There is also the chance that the spring rate (softening or firming up the ride) of new coil springs end up being wrong or at least not what you wanted. To prevent this, find out what your current coils spring rates are and use common sense and a bit of math to adjust accordingly. Remember that coil springs are matched to sway bars from the OEM. Try to do the same.

While ride and handling was not really affected in a good or bad way with the spacers, it was definitely improved with the new Old Man Emu coil springs. There was less body roll in corners, the Jeep felt more steady on the highway, and the off-road ride was much better, and we weren’t bottoming out nearly as often as we were prior to the new spring installation.

While ride and handling was not really affected in a good or bad way with the spacers, it was definitely improved with the new Old Man Emu coil springs. There was less body roll in corners, the Jeep felt more steady on the highway, and the off-road ride was much better, and we weren’t bottoming out nearly as often as we were prior to the new spring installation.