If there is one thing we love, it is the spontaneity of a good wheeling trip. It usually starts with an inkling of an idea, progressing to an itching visualization, and ultimately an all-consuming obsession. If we have a rig that runs, it's a just-add-gas-and-go thing. But when the obsessive draw is to the backcountry of Baja, where the distance between services is measured in days, a back-forty beater won't cut it. Such was the dilemma after a phone call from some buddies for an all-dirt, south-of-the-border bash. The problem: Just two weeks prior to departure our tired old rock rig in the garage was experiencing the slow end of an engine swap. In an instant, our grocery-getter Tacoma became the focal point of our fixation and the impetus for the Two-Week Taco.

Not to be a pavement-pounding disco-mobile with electric tush warmers and headrest-mounted DVD monitors, the Two-Week Taco needed some huevos. The goal: to maintain, if not improve upon, the Taco's stock on-road mannerisms and aptitude for 80-mph highway running (we mean 70 mph in California), while at the flick of a switch (yes, automatic hubs and factory electric locking rear diff), be capable of assaults on high-speed whoop-de-doos, a rocky two-track, or a mired mud bog; a tall order for any rig.

We bought the truck on Craig's List for five grand under Blue Book, already sporting a Leer canopy and Yakima racks for our kayaks. Scrounging the back forty for stuff we already had produced a set of 33-inch Pro Comp XTerrains on fix-'em-with-a-hammer 15x8 steel wheels, a CB radio, a Quick Air II compressor, and a Warn winch from another rig we bought cheap. But the cheesy stock suspension would have to go, and you can't bolt a winch to the paper-thin chrome thing the factory calls a bumper. The problem? Dinero. We just couldn't head to our local wrecker to dig up some heavy-duty coilovers and a winch-mount bumper. A check on Craig's List and eBay yielded what we were afraid of-nothing. We would have to step up to the plate.

Border minus 12 days: With the clock ticking, we made a call to Randy Ellis, owner of Randy Ellis Designs and an authorized Donahoe shop in Phoenix. By noon, we were high-footin' it to Phoenix. Check out the next few pages as we morph our grocery-getting Tacoma into a real-world, trail-worthy rig.

While there are some really good aftermarket lift kits available, some are just that: lift kits. And then there are hockey-puck spacers which raise the ride height but do nothing for the bounce-your-head-through-the-window stock springs. For Baja's backroads, the Two-Week Taco required a purpose-built, application-specific suspension system-one whose genetic fiber is born from off-road racing, but with a penchant for highway cruising. We chose Donahoe Racing, a midsized manufacturer with big-time racing roots. The Donahoe system is not exactly the cheapest method of gaining some altitude under your crossmember, but when it comes to blazing down our favorite trail, the suspension was not the place we wanted to cut corners. That said, we opted for Donahoe's whole tamale: heavy-duty front coilovers, full replacement springs out back, and remote-reservoir nitrogen rear shocks.

With several decades of building custom racecars for the likes of Rod Hall and Walker Evans and a family racing history dating back to the mid '70s, Donahoe didn't start making consumer suspensions until 1999. We talked with company founder, Kreg Donahoe, whose convictions regarding the quality of his product ride the crest of his every statement, and he said, "We may never be the biggest, but then again, we don't build lift kits, we build suspension systems. Our focus is on the quality of travel, not the quantity." By applying our racing experience and thousands of hours of R&D, the one question we continue to ask ourselves is, "Is this as good as it can be, and would I run it on my truck?"

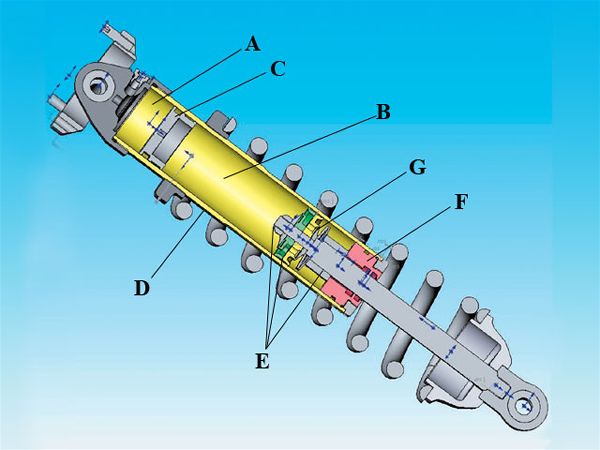

The sole purpose behind a nitrogen-charged shock is to avoid cavitation in the oil. Cavitation is the formation of vacuum air bubbles which reduce the viscosity and effectiveness of the oil as it passes through the shock's valving (G). The nitrogen (A) is separated from the oil (B) by the dividing piston (C), which moves up and down the shock tube (D) to maintain constant pressure as the shock shaft, piston, and valving (E) enter and leave the tube during compression and rebound. Two seals-a dust seal to keep dust out and an oil seal to keep the oil in, located in the seal head (F)-prevent leaks and contamination to the oil.

This exploded cutaway view of Donahoe's digressive valving is just one of the features that make this a great multipurpose shock. Compression (A) and rebound (B) shims are clamped to a multiport piston (C). To maintain a smooth ride during normal daily driving, preset bleed screws (D) allow limited amounts of oil to pass easily. Off road, where the shock must react immediately, such as when hitting a rock or whoop-de-doo at high speed, the piston and valve shims are engineered to allow twice as much fluid to pass through on compression than on rebound. A thinner first valve shim (E) allows the shim pack to be set with a predetermined preload. This reduces spikes in fluid flow and provides smoother performance throughout the range of travel. Lastly, two conical Bellville washers (F), mounted in opposition to each other and with fluid trapped between them, act as an internal droop limiter, eliminating that metal-to-metal clunk sound when your suspension fully extends. In addition, chrome plating is subject to chipping, which ultimately damages the shock seals. To prevent this, Donahoe uses Nitrosteel-treated shock shafts. The patented Nitrosteel process combines nitro-carburizing and surface oxidizing to produce an ultratough and corrosion-resistant surface layer. It is actually part of the shaft rather than an exterior coating. If you wheel near salt water or live where roads are salted in the winter, Nitrosteel is also significantly more resistant to corrosion. While it is a good idea to clean that saline grime off your rig regularly, rumor has it that Donahoe will soon be treating the aluminum shock body to a similar treatment.

PhotosView Slideshow

PhotosView Slideshow