Ken Brubaker

Senior Editor, Four Wheeler

Ken Brubaker

Senior Editor, Four Wheeler

As air suspensions become more and more popular for 4x4s, you may be thinking about converting your solid-axle truck from coil or leaf springs to air springs. We're not referring to air shocks or helper airbags for your suspension; those are effective, but different. We're talking about a complete removal of your truck's coil or leaf springs and subsequent fitment of adjustable air springs as their replacement. Is this new technology? No, semi-tractors and trailers have been using them for years, and with spectacular results. Only lately have manufacturers began integrating the same technology found in semi air suspensions into over-the-counter units that you could install on your vehicle. For instance, the Ford Mighty F-350 Tonka concept vehicle shown at this year's Detroit Auto Show sports eight Air Ride Technologies ShockWave air spring/shock units, and several production 4x4s come with air suspensions as optional equipment.

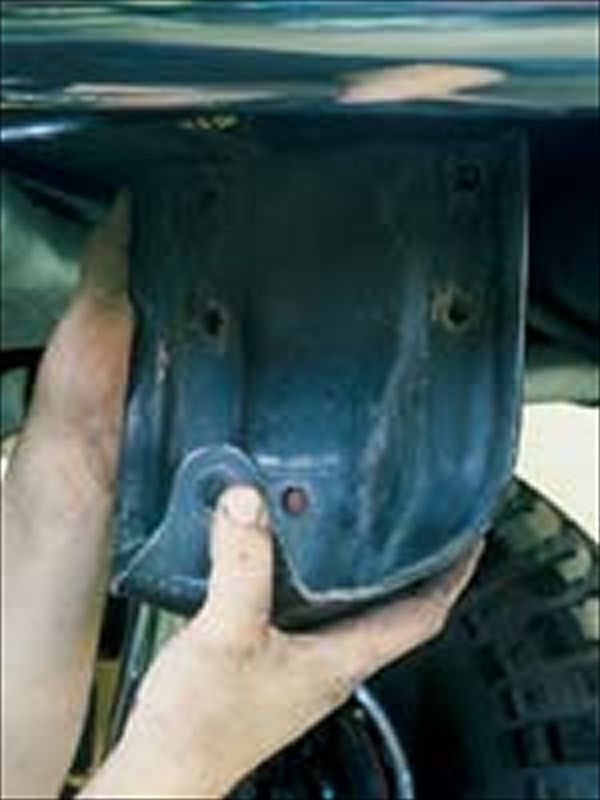

1. Obviously, the first step is to remove the stock suspension. Since the rear of the Dodge would require the most work, we started there by removing the stock leaf springs and the four rivets that hold the rear spring hangers to the frame. Make sure the rear axle is safely supported during disassembly and assembly of the rear suspension.

1. Obviously, the first step is to remove the stock suspension. Since the rear of the Dodge would require the most work, we started there by removing the stock leaf springs and the four rivets that hold the rear spring hangers to the frame. Make sure the rear axle is safely supported during disassembly and assembly of the rear suspension.

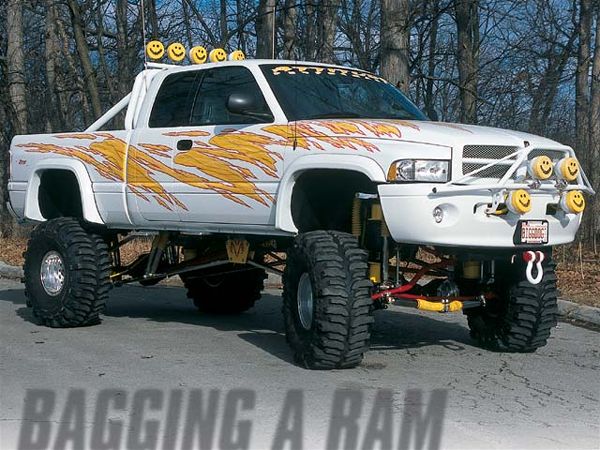

We visited with the crew at Attitude Performance in Elk Grove Village, Illinois, and watched as they installed Air Ride Technologies components on a modified Dodge Ram pickup. Attitude Performance performs many of these air suspension conversions, and shop owner Matt Dinelli works with each truck owner to design a system based on the amount of lift the owner desires and how he will be using the truck. He then orders the appropriate components from Air Ride Technologies to assemble the system. Air Ride Technologies doesn't offer kits for specific vehicle applications. Instead, you simply order what you need for the configuration you desire. The company can supply nearly all of the components and parts needed to complete a change-over. The system you're seeing on this Ram was designed to supply a generous amount of lift, and to work in conjunction with a front and rear four-link suspension. While you may not be planning on this much lift, this story will give you the general idea of what's involved in an installation. Height is generated by a combination of bag height and cup height, but bags could be easily installed on a stock coil-sprung vehicle (like a Wrangler TJ) by simply replacing the coil springs with the bags (because control arms are already in place) and installing the wiring and hoses. Leaf-sprung trucks would require fitment of upper and lower control arms, but once again, Air Ride Technologies and Attitude Performance have these parts available.

Some of the key ingredients to a functional and durable airbag system are bumpstops of appropriate length (so the airbag doesn't fully compress), and limiting straps (so the bag isn't damaged when the suspension is at full droop). Other than that, the installation is straightforward, but depending on the model of truck, installation may require removal of some spring pads and components as well as welding of new bracketry. The result will be a cutting-edge airbag suspension with adjustability, and given what we witnessed, a smooth ride.

Why Air Ride?

Adjustability and ride quality are the top two reasons why air springs are an appealing modification to a 4x4 owner. The ability to vary the amount of air in the bags allows the driver to stiffen or smooth the ride quality of the vehicle at the touch of a button, which is quite handy on bumpy roads or trails.

Much like the adjustable suspension on high-end luxury 4x4s, stiffening the suspension also creates better handling on curvy roads at highway speeds. Of course there's the hauling and towing issue, and the air springs can be easily adjusted to compensate for heavy loads or trailer tongue weights.

Air springs can also be a huge plus on the trail because ride height can be changed easily as the situation demands. Though doing so would require a significant amount of driveline modification, radical suspensions can be created that take advantage of the potential of these units, creating a suspension that could be raised from its default height to almost 12 inches higher. In the real world, though, air-spring suspensions can easily offer a few inches of adjustability for the average truck.