Ali Mansour

Brand Manager, 4WD & Sport Utility

Ali Mansour

Brand Manager, 4WD & Sport Utility

When Jeep launched the Wrangler JK platform in 2007, the company got a lot of things right. The suspension is amazing, the interior light-years nicer than the TJ, and the Rubicon package was even more substantial than the previous model year. As is the case with any new-to-market vehicle, there were bugs to work out. Some of these bugs, however, must be remedied with aftermarket solutions.

Some of the weak points of the ’07-current Wrangler are the front and rear axlehousings. While the internals on our ’07 Rubicon Unlimited’s Next Generation Rubicon Dana 44s are plenty strong (especially after our RCV Performance upgrades), the external features were still lacking. It’s been well documented that the axletubes on JK leave plenty to be desired. The thin-wall tubing is known to bend and even twist free from the centersection when paired with larger tires and hard wheeling.

The stock ball joints are almost as damage prone as the tubes. We’ve experienced this first hand with our previous JKs multiple times. In stock form they are OK at best. Add on some 35 or 37-inch-tall tires and it’s simply a matter of time before they bite the dust. With this JK build, we knew that high-speed wheeling as well as hard rockcrawling would be on the docket frequently.

Given our attraction to the skinny pedal, we decided to invest in our Rubicon’s Dana 44 axles in hopes to keep them alive for the long haul. Using ball joints from the top-tier axle manufacturer Dynatrac and an all-new truss setup from EVO Manufacturing, we spent a day at Low Range 4x4 in Wilmington, North Carolina, outfitting the new accessories on our JK. While we can’t give away everything we’ve done to the Jeep just yet, we will say that we’ve already put the new wares to the test in Moab. Even after some more spirited driving, our front and rear axles are holding strong.

It’s been our experience that nearly all Dana 30 and Dana 44 front JK axles already have some degree of unwanted camber. Whether this is a factory defect or wheeling related, a trip on the alignment machine will tell you how far your axle is out. The first axle upgrade we made (and suggest highly) was with C2 axle gussets from EVO Manufacturing. The stock C’s (aka end forgings) are notoriously weak on the JK front axle. The C2 gussets are designed to brace the end forging to reduce the likelihood of bending. Since we knew we were replacing the stock ball joints, we left them in when we MIG welded the gussets on (it’s best to remove them when welding to the C’s).

It’s been our experience that nearly all Dana 30 and Dana 44 front JK axles already have some degree of unwanted camber. Whether this is a factory defect or wheeling related, a trip on the alignment machine will tell you how far your axle is out. The first axle upgrade we made (and suggest highly) was with C2 axle gussets from EVO Manufacturing. The stock C’s (aka end forgings) are notoriously weak on the JK front axle. The C2 gussets are designed to brace the end forging to reduce the likelihood of bending. Since we knew we were replacing the stock ball joints, we left them in when we MIG welded the gussets on (it’s best to remove them when welding to the C’s).

Ball joints might be one of the least exciting purchases you’ll make, but they are one of the most important. The Dynatrac ball joint kit is designed as the last set of joints you’ll ever need. The rebuildable joints are nearly four times stronger than stock and engineered to handle high impact absorption off-road. This is partly accomplished by using billet steel bodies and heat-treated chromoly stems.

Ball joints might be one of the least exciting purchases you’ll make, but they are one of the most important. The Dynatrac ball joint kit is designed as the last set of joints you’ll ever need. The rebuildable joints are nearly four times stronger than stock and engineered to handle high impact absorption off-road. This is partly accomplished by using billet steel bodies and heat-treated chromoly stems.

We noticed a slight difference between the Dynatrac ball joints we had on our Wrangler years ago and the new ones we were installing here. The difference was in how the lower joint was sized. While the joint is still on-par with the same strength levels, it now has a slightly lower profile so it doesn’t interfere with the larger late-model U-joints, or in our case, CV boots for those running RCV Performance CV axleshafts.

We noticed a slight difference between the Dynatrac ball joints we had on our Wrangler years ago and the new ones we were installing here. The difference was in how the lower joint was sized. While the joint is still on-par with the same strength levels, it now has a slightly lower profile so it doesn’t interfere with the larger late-model U-joints, or in our case, CV boots for those running RCV Performance CV axleshafts.

As we previously mentioned, it’s not uncommon for the axle end forgings to be at different angles. This misalignment can be an additional contributor to the stock JK ball joints failing. The Dynatrac joints are designed to work with the various angles and forces that could be the result of a tweaked C or hard wheeling.

As we previously mentioned, it’s not uncommon for the axle end forgings to be at different angles. This misalignment can be an additional contributor to the stock JK ball joints failing. The Dynatrac joints are designed to work with the various angles and forces that could be the result of a tweaked C or hard wheeling.

Installing the new ball joints will only require a ball joint tool and included joint spacer from Dynatrac. Be sure to clean the joint hole thoroughly and always use anti-seize on the bore hole when installing the new joints.

Installing the new ball joints will only require a ball joint tool and included joint spacer from Dynatrac. Be sure to clean the joint hole thoroughly and always use anti-seize on the bore hole when installing the new joints.

In terms of axles bracing, EVO Manufacturing offers a few avenues to go. The company’s latest offering is known as the ProTek 44 truss system. The front-axle truss kit is comprised of 3/16-inch laser-cut and CNC press-brake formed one-piece steel sections. As you see it here, it is just the truss kit that’s specific for the Rubicon 44. Other options and kits are also available.

In terms of axles bracing, EVO Manufacturing offers a few avenues to go. The company’s latest offering is known as the ProTek 44 truss system. The front-axle truss kit is comprised of 3/16-inch laser-cut and CNC press-brake formed one-piece steel sections. As you see it here, it is just the truss kit that’s specific for the Rubicon 44. Other options and kits are also available.

EVO uses a 3/16-inch steel backbone for the main truss and outer sections. Once the axle is prepped, you will weld the backbones in first and then install the outer sections, which are keyed for precise placement.

EVO uses a 3/16-inch steel backbone for the main truss and outer sections. Once the axle is prepped, you will weld the backbones in first and then install the outer sections, which are keyed for precise placement.

The EVO kit is designed in sections to minimize the shrinkage and heat effects of welding. This creates an easier install, with a reduced chance of the metal warping.

The EVO kit is designed in sections to minimize the shrinkage and heat effects of welding. This creates an easier install, with a reduced chance of the metal warping.

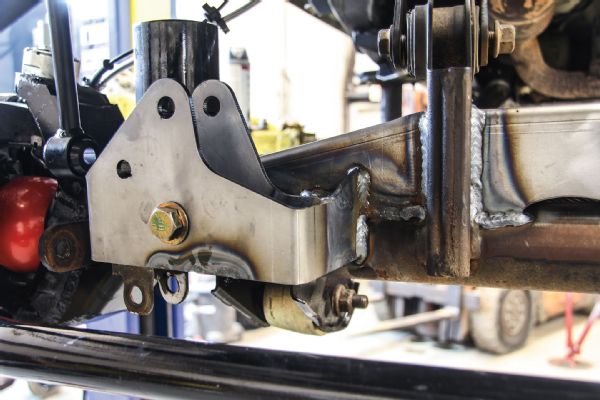

A key feature of the ProTek 44 truss kit is the 1/4-inch steel bridge that connects the left and right truss sections. This not only creates a more effective axle truss, but keeps you from having to weld to the differential casting.

A key feature of the ProTek 44 truss kit is the 1/4-inch steel bridge that connects the left and right truss sections. This not only creates a more effective axle truss, but keeps you from having to weld to the differential casting.

Since we are using an EVO Mfg. draglink flip, we opted for the weld-on track bar bracket. This setup raises the track bar at the axle, which increased the roll-center, thus creating better and safer handling both on-road and off.

Since we are using an EVO Mfg. draglink flip, we opted for the weld-on track bar bracket. This setup raises the track bar at the axle, which increased the roll-center, thus creating better and safer handling both on-road and off.

The rear axle in the JK is one spot that is often overlooked, but has faults of its own. We’ve broken the plug welds on the JK’s rear axlehousing before, so adding a truss is a no-brainer at this point. EVO Mfg.’s 3/16-inch steel ProTek 44 truss is a precision fit that only requires a little pre-welding grinding prep on the axle. While you could weld it to the casting, we opted to simply use our MIG welder to fuse the truss to the axletubes.

The rear axle in the JK is one spot that is often overlooked, but has faults of its own. We’ve broken the plug welds on the JK’s rear axlehousing before, so adding a truss is a no-brainer at this point. EVO Mfg.’s 3/16-inch steel ProTek 44 truss is a precision fit that only requires a little pre-welding grinding prep on the axle. While you could weld it to the casting, we opted to simply use our MIG welder to fuse the truss to the axletubes.

The rear truss didn’t interfere with any of the stock or aftermarket components, but we suggest asking EVO Mfg. about your specific setup before ordering the ProTek. One thing we did note is that clearance to the rear locker plug is very tight. While this didn’t cause us any issues, it will be a tight fit if we ever need to remove the upper actuator for the Rubicon’s stock electric locker.

The rear truss didn’t interfere with any of the stock or aftermarket components, but we suggest asking EVO Mfg. about your specific setup before ordering the ProTek. One thing we did note is that clearance to the rear locker plug is very tight. While this didn’t cause us any issues, it will be a tight fit if we ever need to remove the upper actuator for the Rubicon’s stock electric locker.

As you’ve likely noticed from the other photos, we opted to upgrade the differential covers with ones from Dynatrac. The Dynatrac covers are significantly thicker than stock, which will be helpful for when we inevitably grind them into an obstacle off-road. The recessed cover hardware is also a nice bonus for when we need to get into the differential past a rough patch on the trail.

As you’ve likely noticed from the other photos, we opted to upgrade the differential covers with ones from Dynatrac. The Dynatrac covers are significantly thicker than stock, which will be helpful for when we inevitably grind them into an obstacle off-road. The recessed cover hardware is also a nice bonus for when we need to get into the differential past a rough patch on the trail.

Our front axle is almost complete. In fact, we would say its 98 percent there. Due to a shipping delay and lack of time, we didn’t have a chance to install our EVO control arm skidplates. Once we burn them in, our axles should have everything they need to survive the dirt and tarmac with ease.

Our front axle is almost complete. In fact, we would say its 98 percent there. Due to a shipping delay and lack of time, we didn’t have a chance to install our EVO control arm skidplates. Once we burn them in, our axles should have everything they need to survive the dirt and tarmac with ease.