Ken Brubaker

Senior Editor, Four Wheeler

Contributors:

Four Wheeler Archives

Ken Brubaker

Senior Editor, Four Wheeler

Contributors:

Four Wheeler Archives

There are few bigger joys in life than getting a smokin' new set of wheels for your rig. OK, maybe winning the lottery or getting a date with a supermodel is a tad more invigorating, but wheels are pretty darn good. The beauty of wheels is that as long as you get the same bolt pattern, you can just bolt 'em on and go, right? Actually no, that's only a part of the equation. The other part is backspacing and offset, and if they're wrong, chances are you won't be rollin'.

From the factory, your rig was fitted with wheels carefully designed by engineers to allow for adequate clearance between the wheel and tire and items like tie-rod ends, brake calipers, fenderwells, the frame, and other exposed components. If you try to fit a different wheel-and-tire combination, you may find that contact may occur between these items and the wheel and/or tire during standard steering maneuvers or suspension articulation. The way to avoid this is to make sure you have wheels with the proper offset and backspacing for the tire you'd like to run on your truck.

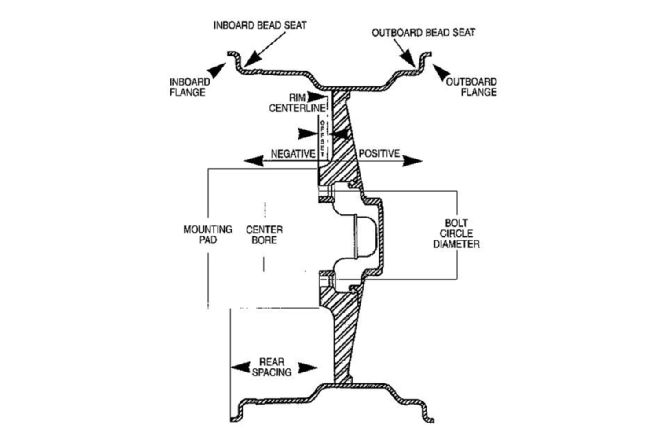

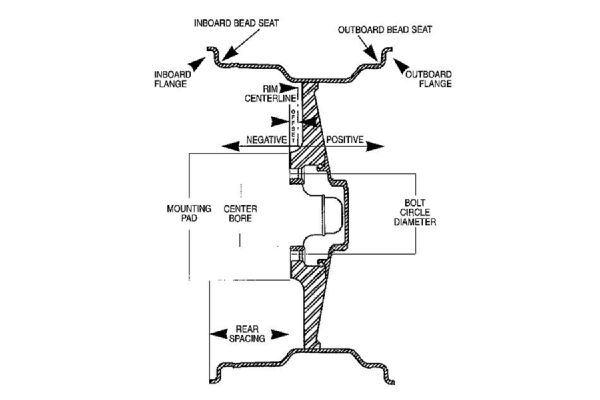

First, let's define what each is. Backspacing is the distance from the inside bolting surface of the rim to the outer edge of the inboard side of the rim. Offset is the distance from the exact center of the rim to the outer edges of the rim. Positive offset means that the center of the wheel is moved towards the vehicle. Negative offset means that the center of the wheel is moved away from the vehicle. The included graphic image illustrates this.

Most stock wheels have a positive offset. When you go to a larger tire, the wheel backspacing needs to change so that the bigger tire won't contact the aforementioned items. Most often, when switching to aftermarket wheels this means that you'll be using a wheel with a negative offset. Naturally, this creates room for a larger tire. There are downsides to a negative offset, including an increased turning radius and more leverage on the lugs, bearings, spindles, and axlehousing. Further, chances are the tire will protrude past the fender, which is illegal in some states, requiring you to install fender flares. Fitting wider wheels can also increase sensitivity to tracking and require greater steering efforts. While these issues are inherently unavoidable with negative offset, you'll have to take them into consideration. Obviously, you'll want to use a tire with the proper backspacing and offset to create the needed clearance without creating too much leverage. The upside of a negative offset, in addition to fitting a larger tire, is that the vehicle will now be slightly wider, thus improving stability.

The reality is that if your vehicle is still running the stock axles, there's a good chance you can simply query the wheel manufacturer for the recommended wheel for your application and they'll be able to recommend the proper sizing. After all, they are wheel experts and they have gobs of information at their fingertips. Talk with the technicians and scour their catalogs. They want to sell you wheels, and they want them to fit correctly the first time. If you want to measure backspacing and offset yourself, the accompanying sidebar will tell you how to do it. If you're in a position where you need custom wheels, fear not, because there are scores of custom wheel manufacturers like Stazworks (double internal bead-lock wheels only) and Stockton Wheel Service that can make a set of custom wheels for you.

Determining the actual backspacing of a wheel is easy. Since it's the distance from the mounting surface to the edge of the inboard side of the wheel, it simply needs to be measured. With the wheel facedown, rest a ruler horizontally along both edges (beads) of the wheel. Now take a tape measure and measure the distance from the ruler to the mounting pad of the wheel. That figure is your backspacing. Calculating a wheel's offset is even easier. Measure the wheel's overall width, subtract its backspace and divide by two.

Wheel spacers are simply an inexpensive way to create clearance between a wheel/tire and items like steering components and brakes. There are literally scores of sources for spacers, and there are a vast number of thicknesses available. Most manufacturers use high-grade aluminum, and many have weight and tire size ratings for their spacers. Don't confuse wheel spacers with wheel adapters. Wheel adapters are used to fit wheels with a different bolt pattern than the axles. Wheel spacers simply move the wheel away from the hub.

Adding wheel spacers will have the effect of running a wheel with a negative offset. They give you room for larger tires, thus solving fitment issues. The downside is that moving the wheel away from the hub puts increased stress on the wheel bearings, spindle, knuckle, and the axlehousing itself, just like wider wheels. Also remember that because of the fact that the spacers bolt onto the hub and then the wheel bolts to the spacer, you now have two sets of lug nuts to torque and re-torque.

The most important tip to remember when purchasing wheel spacers is to carefully measure things out ahead of time so that you can purchase spacers that are no thicker than they have to be.