Miller Electric Mfg. Co. has a highly portable welder with some very interesting features. Many people are uncertain whether to purchase a MIG welder or a TIG machine, and this clever unit does both, plus it can do regular arc welding as well. Making a multi-process machine is not as easy as you might think. MIG welding requires a constant voltage power supply, while TIG and arc welding use constant current. Miller has done a great job of creating a compact, inverter-based welding machine that can do both. It comes in a durable package that weighs only 29 pounds. This revolutionary machine won a Best New Product award at the 2012 SEMA show.

I had the opportunity to test the new Multimatic 200, and put it through its paces. The first thing that caught my attention was the size and portability of the unit. It's packaged in a sturdy, impact-resistant plastic case, about the size of a piece of carry-on luggage. It comes standard with a MIG gun and a lead for arc welding. A TIG torch is an option, as is a spool gun that can be used for MIG welding aluminum. All of these work with either 120V or 230V input. The machine has a clever power cable with a multi-voltage plug, which allows you to quickly swap the end piece to work with outlets for either voltage; no tools required.

This is the Miller Multimatic 200, a clever, compact multifunction machine that can be used for TIG, MIG, and straight arc welding. The MIG gun is attached in this photo.

This is the Miller Multimatic 200, a clever, compact multifunction machine that can be used for TIG, MIG, and straight arc welding. The MIG gun is attached in this photo.

It's quite easy to plug in whatever hand piece you want to use—a TIG torch, a MIG gun, the spool gun, or the arc rod holder—and then connect a bottle of the appropriate welding gas. (Note: straight arc and flux-core MIG welding require no gas, making the package even more portable.)

The MIG gun and cable were easy to attach, with no tools required. The case is large enough to take a full-size, 10-pound spool of wire, but to keep the weight manageable, I used a small one. I connected a bottle of C25 gas (75 percent argon, 25 percent CO2) the best choice for making a high-quality weld on steel.

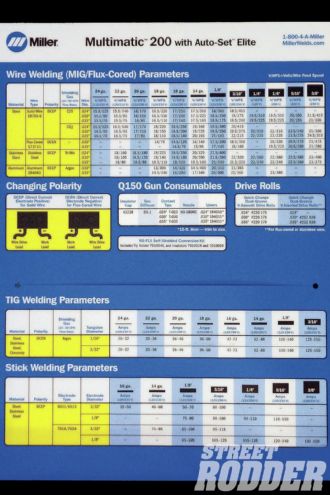

Before welding, the voltage and wire speed settings are made with knobs on the front panel. This machine has the "auto-set" feature, where you simply enter the wire diameter and the material thickness, and the machine makes the proper settings for you. Alternately, there's a handy chart of recommended parameters inside the case, which you can dial in manually. The recommended settings are optimized for typical welding situations, and it's easy to fine-tune them if you want. I really liked the simplified, digital control panel, with the brightly illuminated display.

Inside the case there is a handy chart with the recommended settings for each wire size and material thickness.

Inside the case there is a handy chart with the recommended settings for each wire size and material thickness.

I was impressed with the quality of the weld I made, and the ease of changing the settings to work with thicker or thinner metal. The little machine packs 200 amps of power, and it can weld steel up to 3/8-inch thickness.

Next, I connected the Spoolmate 100 Spool Gun, loaded with 4043 aluminum wire. The spool gun plugs in like the standard MIG gun, and it only took a couple of minutes to switch the machine over. Aluminum is welded with straight argon gas, so I had to connect a different gas bottle to the machine.

One thing I have to say about using a spool gun on aluminum is it's fast. With the correct settings, it's easy to get full penetration on aluminum plate up to 1/4-inch thickness. While you don't get the same "dime-on-dime" bead definition as you do with a TIG weld, it still makes a smooth, low-profile weld if the settings are made correctly.

For my last test, I connected the TIG torch. The Multimatic 200 TIG welds in DC only, which is the mode used for metals like mild steel, stainless steel, and chromoly. In the TIG mode, the arc is initiated with the "lift-arc" process, where the electrode is touched to the work piece, then pulled away a short distance, establishing the welding arc. Note that this lift-arc process is quite different from the "scratch-start" mode some other TIG welders use. With the scratch-start system, the arc is initiated at the full voltage setting, which runs the risk of contaminating the tungsten electrode as the arc starts. With the cleverly engineered lift-arc system, the voltage is very low initially, and once the arc is established, it ramps up to the voltage set on the front panel. This virtually eliminates any chance of fouling the tungsten, plus it prevents high-frequency interference with any sensitive electronics that may be in use near the welder.

The settings are made on front panel, which has a nice digital readout. There’s an auto-set feature, so you can dial in the wire diameter and material thickness, and the machine automatically sets the voltage and wire speed for you.

The settings are made on front panel, which has a nice digital readout. There’s an auto-set feature, so you can dial in the wire diameter and material thickness, and the machine automatically sets the voltage and wire speed for you.

The TIG torch has a button to start and stop the arc, and a thumb-wheel to adjust the current. This system works nicely and there's an optional foot control that can be used with the machine as well. I normally prefer a foot control for TIG welding, but the Miller TIG torch hand controls are the nicest I've used. In fact, if you are welding in an awkward position, it's sometimes impossible to use a foot pedal, so sometimes a hand control is essential.

TIG welding with this machine is a delight. The arc control is superb, and the circuitry keeps the arc very stable from start to finish.

It's easy to connect the "stinger" for arc welding, too, but I prefer MIG and TIG welding for the type of work I do.

All in all, I like this little machine a lot. Its strongest feature is its small size and portability, plus giving you the option for MIG, TIG, or arc welding with the same machine. While it's more expensive than single-purpose machines, if you need the portability, or the multi-process features, it's a great way to go.