Bandsaw blades are categorized by metallurgy, thickness, and tooth count per inch (TPI). Gauging by the thickness of metal you're working with, choose a tooth count that allows two or three teeth to cut into the metal at the same time, but no more. As the first tooth begins cutting, it forms a chip. If the space between the teeth is too small, the chip has nowhere to go, and the blade loads up and breaks off the first tooth, which gets stuck in the second tooth, and so on. Cut at a low speed to avoid overheating the blade. For soft metals like aluminum, wax the blade so it doesn't gum up.

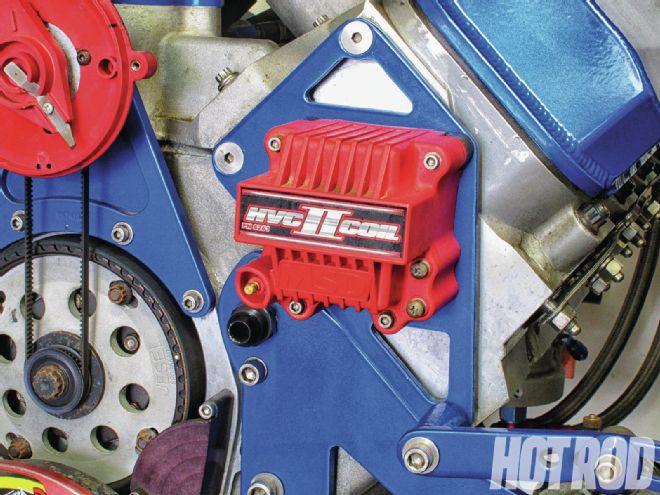

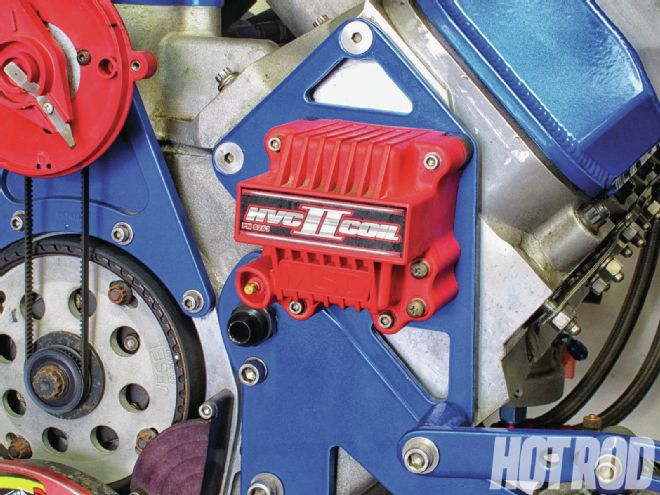

<STRONG>16</STRONG> If you're as weight-conscious as we are, you can also take an end mill to the interior of the bracket and remove any unnecessary material. It's a functional and attractive mod. The tools mentioned above were used to build all of the brackets and mounting plates on this big-block Chevy.

<STRONG>16</STRONG> If you're as weight-conscious as we are, you can also take an end mill to the interior of the bracket and remove any unnecessary material. It's a functional and attractive mod. The tools mentioned above were used to build all of the brackets and mounting plates on this big-block Chevy.