How many times have you been to the doctor or hospital for some ailment and the diagnosis was wrong? Getting to the root of most any problem within a complex situation is tough-even for professionals. And while you may take a trip to the emergency room for a pesky or persistent headache that could be some sort of allergy or worse, the symptoms can be all too similar for a number of scenarios.

Mechanical problems are quite comparable. If your truck doesn't start, it could be something as simple as an empty gas tank, clogged fuel filter, bad coil, or a multitude of other possibilities, but in order to diagnose the cause, we must rule out what we know it's not.

Last month we covered the basics on clutches as far as the most popular for street use, how they work, and the parts that are used in conjunction, like pressure plates, flywheels, and throwout bearings. This month we are looking into common clutch failures and how to diagnose the problem that caused the damage in the first place. If your clutch did more than just wear out and failed prematurely, it's very important to figure out why, instead of just replacing the parts and having them fail again; wasting lots of time and money-especially if you farm the work out!

The assembly and installation of the clutch components has plenty to do with the success and life of the parts; the other main factor is your personal driving style/habits. If you are working on the stock-type clutch for your truck, it's always wise to have a copy of the factory manual for its installation/maintenance specs, like bolt torque specs, pedal freeplay, if any special tools are required, and of course the actual R&R of the parts. While under your truck with the transmission out, be sure and check all related clutch parts for wear or possible problems. The clutch linkage starting from the clutch pedal bushings, to the bell crank (aka Z-bar), to the clutch fork and pivot ball, should be inspected for wear or damage. If you find any questionable parts, they should be repaired or replaced. If your truck has a hydraulic release system, check for any hydraulic leaks in the clutch master and hoses. If your vehicle is cable equipped, the cable should be checked for damage, stretch, fraying, excessive resistance, or binding. If any of these conditions are found, replace the clutch cable and always inspect the throwout bearing collar for signs of wear or galling.

Here's a list of do's and don'ts when it comes time to replace your clutch:

It's simple and obvious, but make sure you have the correct replacement parts before installing any of them, as well as the proper clutch alignment tool. Failure to use a pilot tool to align the clutch disc could result in damage to the disc during installation of the transmission.

Always check the new clutch disc for proper fitment on the transmission input shaft prior to installation. Make sure the input shaft splines are free of wear and twisting.

Whenever you have the clutch out, even if you don't replace it, it's usually a good idea to replace the old throwout bearing and pilot bearing while you're there. They are inexpensive compared to pulling the clutch out again, and I speak from experience! About 10 years ago, I had a '50 Ford I replaced a clutch in. I bought an old but N.O.S. throwout bearing that started squealing no less than three days later, and I had to replace it again.

Never combine a worn pressure plate with a new clutch disc or vice versa. Always replace both the pressure plate and clutch disc with new components.

Replace any worn components such as input shaft collars, clutch forks, slave /master cylinders, etc.

Always properly resurface or replace the flywheel. Resurfacing a flywheel with any device (say an angle grinder) other than a dedicated flywheel-resurfacing machine is not recommended. Also, always clean the surfaces of the pressure plate and flywheel with brake parts cleaner or acetone before installing.

Be sure to install the clutch disc with the side indicating "flywheel side" against the flywheel. If your clutch disc is not marked indicating which side of the clutch disc is the flywheel side, please contact its manufacturer.

Always torque all hardware to factory specifications. Replace hardware if it's worn or if the factory service manual recommends replacement. Proper hardware (shouldered bolts, dowel pins, etc.) used to affix the pressure plate to the flywheel and the flywheel to the crankshaft are special pieces and NOT ordinary hardware. Failure to use proper hardware could result in a vibration, improper clutch operation, or clutch failure.

Do not allow any petroleum-based products (grease, oil, lube, and so on) to contaminate the clutch disc friction material. If contaminated, the disc may cause clutch chatter, slippage, premature wear, or improper clutch operation.

Avoid mixing brands within the clutch system. Most companies design their products to work best with their own products. This helps guarantee proper performance and lifespan. Also, you'll have an easier time on a tech line or with a warranty should anything go wrong.

Seek out and follow the required break-in procedure for your new clutch assembly. Each manufacturer will vary, but following it is necessary to ensure proper seat-in of the friction material, full performance, and proper heat cycling. Failure to do so may result in premature wear, decreased holding capacity, improper clutch operation, and will void most warranties.

Most any clutch company will be happy to discuss your clutch problems/needs with you over the phone and help you select the right clutch. You shouldn't be too worried about them trying to talk you into an expensive unit that's overkill for your daily driver or weekend toy because they want you to be happy with their clutch and retain you as a loyal customer. Installing a clutch into your truck that's anything other than what you really need can cause everyone involved quite a bit of grief, not to mention money.

Below is valuable reference material from Centerforce for people with three pedals at their feet and anyone thinking about ever owning a truck with a gearbox. Be sure to file this issue into your library of old motors and factory shop manuals should you start "slipping."

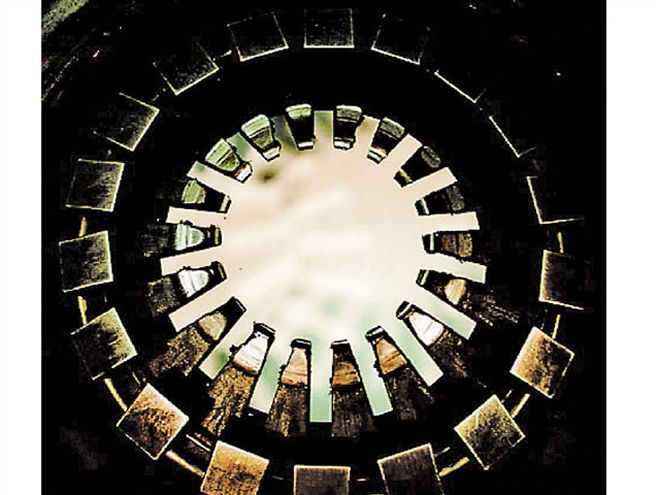

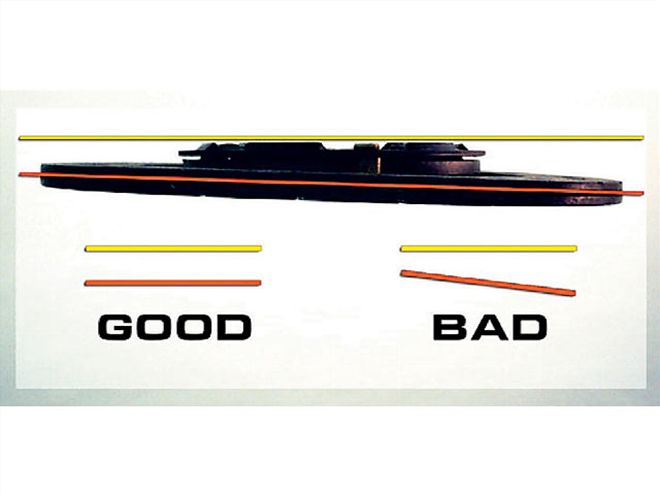

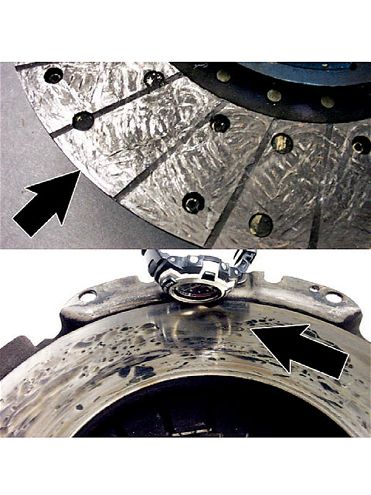

Pressure Plate Overheated-Severe Hot Spots

Symptoms:

Clutch slips-does not hold vehicle power

Clutch chatters

Clutch wore out prematurely

Possible Causes:

Improper break-in procedure

Clutch excessively preloaded-improper adjustment

Excessive slipping from driving style

Solutions:

Replace clutch assembly

Inspect and resurface flywheel-replace if necessary

Adjust clutch pedal freeplay

Follow proper break-in procedure

Evaluate driving style

Worn Diaphragm Spring Fingers on Pressure Plate

Symptoms:

Difficult clutch engagement or disengagement-difficult shifting

Difficulty adjusting clutch pedal freeplay

Clutch slips-does not hold vehicle power

Clutch wore out prematurely

Possible Causes:

Improperly installed throwout bearing

Clutch excessively preloaded-improper adjustment

Solutions:

Replace throwout bearing with correct part and install properly

Inspect transmission guide tube and bearing collar for wear-repair or replace if necessary

Adjust clutch pedal freeplay

Replace clutch assembly

Inspect and resurface flywheel-replace if necessary

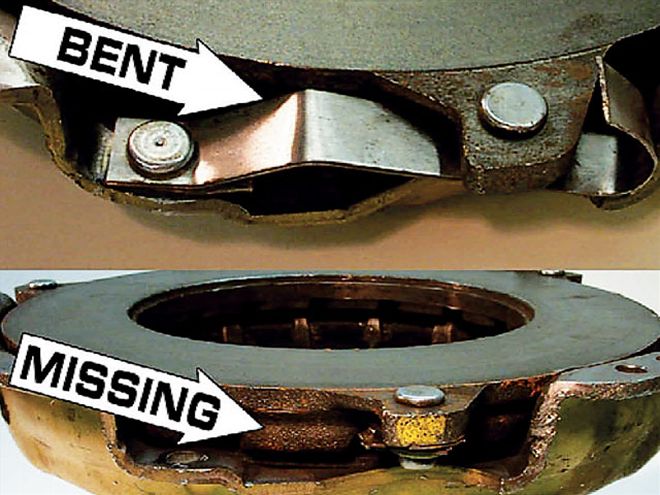

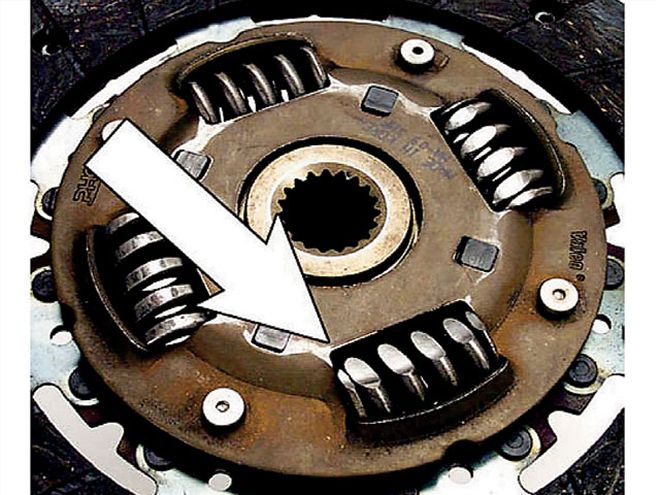

Pressure Plate Drive Strap(s) Bent/Broken/Missing

Symptoms:

Difficult clutch engagement or disengagement-difficult shifting

Noise from clutch

Possible Causes:

Abusive downshifting

Using clutch as a brake to slow vehicle

Missed shifts

Solutions:

Replace clutch assembly

Inspect and resurface flywheel-replace if necessary

Evaluate driving style-avoid abusive downshifting

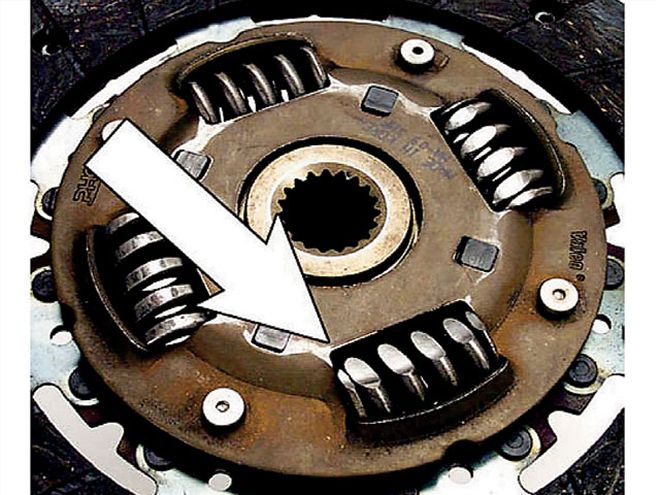

Pressure Plate Improperly Balanced

Symptoms:

Vibration from engine/transmission/shifter

Weight system shifted off center

Possible Causes:

Improper flywheel counterbalance

Improper hardware

Clutch improperly balanced

Flywheel improperly balanced

Solutions:

Verify flywheel counterbalance, if equipped

Use proper hardware-shouldered bolts or locating dowel pins to retain pressure plate to flywheel

Replace clutch assembly

Inspect, resurface, and balance flywheel-replace if necessary

Diaphragm Spring Fingers OverTraveled-Hitting Clutch Disc

Symptoms:

Clutch slips-does not hold vehicle power

Difficult clutch engagement or disengagement-difficult shifting

Clutch wore out prematurely

Noise from clutch

Possible Causes:

Clutch excessively preloaded-improper adjustment

Improper pressure plate and clutch disc combination

Improper flywheel step/cup dimension

Solutions:

Replace clutch assembly

Inspect and resurface flywheel-replace if necessary

Adjust clutch pedal freeplay

Pressure Plate Bent

Symptoms:

Pressure plate won't bolt evenly to flywheel

Difficult clutch engagement or disengagement-difficult shifting

Clutch chatters

Possible Causes:

Pressure plate dropped

Improper flywheel step/cup dimension

Improper hardware used to fasten pressure plate to flywheel

Debris between pressure plate and flywheel

Solutions:

Replace clutch assembly

Inspect and resurface flywheel-replace if necessary

Use proper hardware-torque bolts to factory specification

Clean surfaces prior to installation

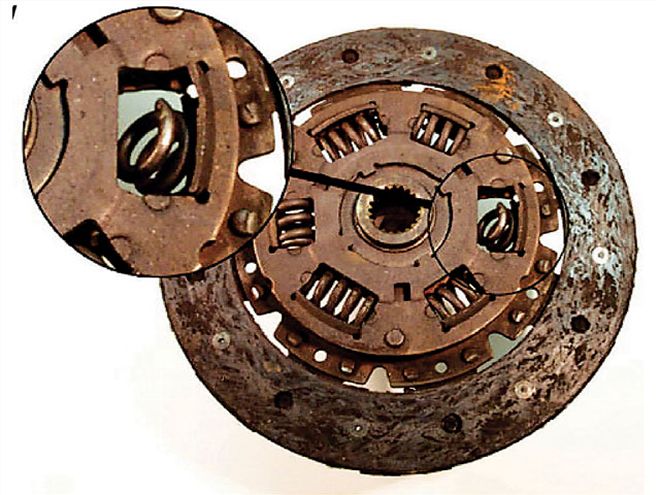

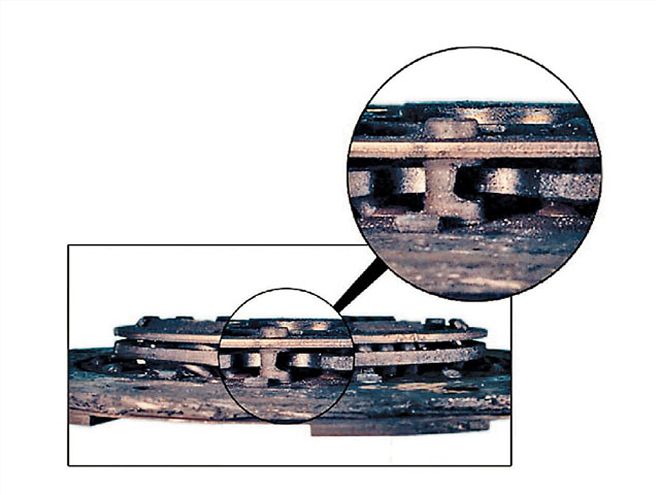

Clutch Disc Hub Springs Loose/Missing

Symptoms:

Noise from clutch

Difficult clutch engagement or disengagement-difficult shifting

Possible Causes:

Clutch disc installed improperly

Transmission misalignment

Abusive upshifting/downshifting

Worn or missing pilot bearing/bushing

Solutions:

Replace clutch disc-install properly

Inspect and resurface flywheel-replace if necessary

Inspect pilot bearing/bushing-replace if necessary

Evaluate driving style-avoid abusive shifting

Clutch Disc Hub Splines Worn Excessively/Hub Spring Pack Cracked

Symptoms:

Noise from clutch

Difficult clutch engagement or disengagement-difficult shifting

Rapid pilot bearing/bushing wear

Possible Causes:

Transmission/bellhousing misalignment

Transmission hung on clutch disc by input shaft during installation

Worn or missing pilot bearing/bushing

Solutions:

Check transmission and bellhousing alignment

Inspect input shaft for wear

Replace clutch disc

Replace pilot bearing/bushing

Support transmission when installing

Clutch Disc Oil Contaminated

Symptoms:

Clutch chatters

Clutch slips-does not hold vehicle power

Clutch wore out prematurely

Possible Causes:

Oil leak from engine or transmission

Solutions:

Repair oil leak

Thoroughly clean bellhousing and release components

Replace clutch assembly

Inspect and resurface flywheel-replace if necessary

Clutch Disc Overheated/Abused

Symptoms:

Clutch won't release

Clutch chatters

Clutch slips

Clutch vibrates

Clutch wore out prematurely

Possible Causes:

Excessive engine power

Improper break-in procedure

Clutch excessively preloaded-improper adjustment

Solutions:

Adjust clutch pedal freeplay

Replace clutch with upgraded clutch assembly

Inspect and resurface flywheel-replace if necessary

Follow proper break-in procedure

Evaluate driving style

Clutch Disc Bent

Symptoms:

Difficult clutch engagement or disengagement-difficult shifting

Noise from clutch

Possible Causes:

Clutch disc installed incorrectly

Transmission hung on clutch disc by input shaft during installation

Part damaged during shipping

Solutions:

Replace clutch disc

Inspect pressure plate-replace if wear is found

Evaluate transmission installation-support transmission during installation

Clutch Disc Drive Stop Rivets Abused/Worn/Broken

Symptoms:

Clutch wore out prematurely

Noise from clutch

Possible Causes:

Abusive downshifting/upshifting

Side-step launch of vehicle

Solutions:

Replace clutch assembly

Inspect and resurface flywheel-replace if necessary

Evaluate driving style-avoid using clutch to slow vehicle and abusive launching

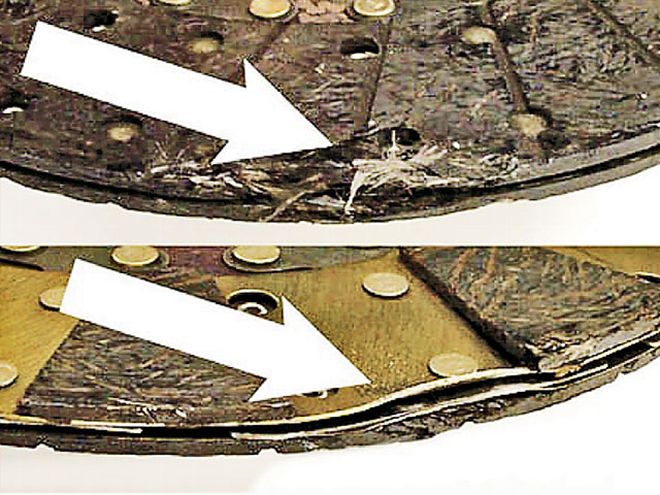

Clutch Disc Friction Material Cracked/Broken/Missing

Symptoms:

Clutch slips-does not hold vehicle power

Difficult clutch engagement or disengagement-difficult shifting

Noise from clutch

Possible Causes:

Abusive downshifting/upshifting

Side-step launch of vehicle

Improper break-in procedure

Missed shifts

Solutions:

Replace clutch with upgraded clutch assembly

Inspect and resurface flywheel-replace if necessary

Follow proper break-in procedure

Evaluate driving style-avoid abusive shifting and launching

Clutch Disc Hitting Flywheel or Flywheel Bolts

Symptoms:

Difficult clutch engagement or disengagement-difficult shifting

Noise from clutch

Hub spring(s) loose in clutch disc

Difficulty adjusting clutch pedal freeplay

Possible Causes:

Clutch disc installed backwards

Flywheel bolts improper-head of bolt too large

Flywheel worn-improper resurfacing or too thin

Solutions:

Replace clutch disc

Inspect pressure plate-replace if wear is found

Inspect flywheel crankshaft bolts-replace if wear is found or head is too large

Inspect flywheel-replace if improperly dimensioned

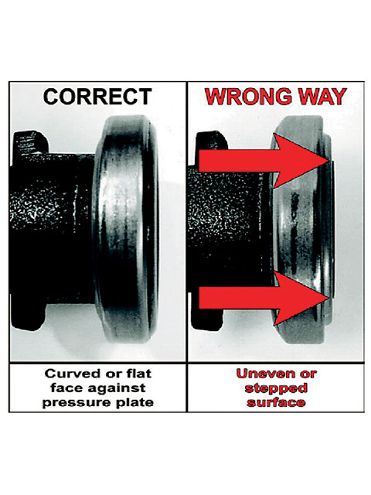

Throwout Bearing Installed Backward

Symptoms:

Noise from throwout bearing

Hard and/or pulsating clutch pedal

Difficult clutch engagement or disengagement-difficult shifting

Possible Causes:

Bearing installed incorrectly

Solutions:

Replace throwout bearing-install correctly

Inspect pressure plate-replace if wear is found

Inspect transmission guide tube and bearing collar for wear-repair or replace if necessary

Clutch Assembly Glazed

Symptoms:

Clutch slips-does not hold vehicle power

Clutch wore out prematurely

Possible Causes:

Improper break-in procedure

Clutch excessively preloaded-improper adjustment

Excessive slipping from driving style

Oil leak from engine or transmission

Solutions:

Repair oil leak-if necessary

Thoroughly clean bellhousing and release componentsReplace clutch assembly

Inspect and resurface flywheel-replace if necessary

Adjust clutch pedal freeplay

Follow proper break-in procedure

Evaluate driving style

Clutch Disc Friction Material Chipped/Bent

Symptoms:

Difficult clutch engagement or disengagement-difficult shifting

Clutch slips-does not hold vehicle power

Noise from clutch

Possible Causes:

Clutch disc dropped during installation or removal

Clutch disc not installed using alignment tool

Solutions:

Replace clutch disc

Use care when installing or removing clutch disc

Throwout Bearing and/or Clutch Fork Improperly Installed

Symptoms:

Hard and/or pulsating clutch pedal

Noise from throwout bearing

Difficult clutch engagement or disengagement-difficult shifting

Possible Causes:

Fork and/or bearing installed incorrectly

Clutch excessively preloaded-improper adjustment

Clutch release linkage worn or damaged

Solutions:

Inspect throwout bearing for wear-replace if wear is found

Inspect transmission input shaft collar for wear-replace if wear is found

Inspect pressure plate diaphragm fingers-replace if wear is found

Install clutch fork/throwout bearing correctly

Adjust clutch pedal freeplay

Inspect clutch release linkage-replace if wear is found