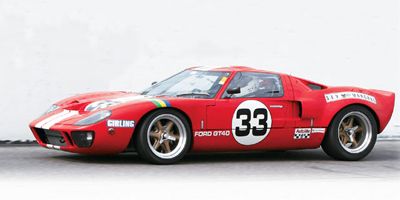

Much of the kit car hobby is built around the auto racing legends of the '60s-the Cobra, the Daytona Coupe, Porsche 550 Spyder, and the GT 40, to mention a few. It has always been a challenge for me to build a car that was street-legal and fun to take to cruise nights, yet kept to the theme of a vintage race car. That bar has been raised even higher with the growing popularity of open track days, driving schools, and club racing events, which leads me to the premise of my latest build. How do you take a replica from any given manufacturer and build a street-legal car that maintains its true vintage spirit, but also is competitive on a weekend excursion to the local road race circuit?

For this project I chose a GT40 from Race Car Replicas in Clinton Township, Michigan. All of the things we did to make this project a dual-purpose street/track car can be done by anyone to most any replica with a little thought at the beginning to achieve the desired end result. This is a huge project to tackle, so I thought it would be best to discuss it in phases. In this article we will be discussing the intricacies of the engine build.

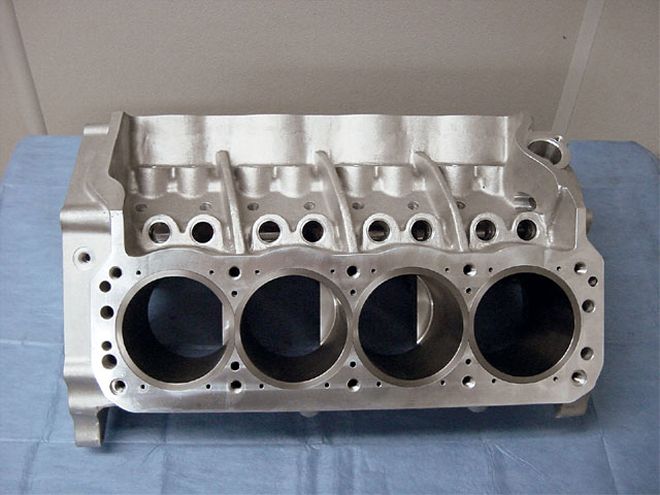

This is where the fun begins. It looks more like a beautiful sculpture than an engine part. (At least it does to some of us!) This block saves us about 94 pounds vs. the iron block-not a bad start!

This is where the fun begins. It looks more like a beautiful sculpture than an engine part. (At least it does to some of us!) This block saves us about 94 pounds vs. the iron block-not a bad start!

After your car is ordered there is usually some lag time before it's delivered. We took advantage of this time to build the powerplant that will propel our race car down the front straight at Road America and to the local cruise night when we get back home. It's relatively easy to build a 13.0:1 compression engine to run at 7,000 rpm on a racetrack burning 110-octane fuel, or an engine that cruises at 1,800 rpm all day long and idles comfortably at the next traffic light. It's another thing all together to build an engine to do both!

With this in mind, I headed to Greenville, Illinois, to visit "Lumpy" Loughary and Jim at Performance Motorsports Systems. Lumpy has a great reputation for building high-performance race engines for clients across the country, largely because his engines build smooth power and torque across the range and have proven to be very durable. Simply put, they win races.

I went into Lumpy's office, poured a cup of coffee, sat down, and explained the plan. He was up for the challenge. We spent the next couple of hours talking about compromise, what I could live with in order to get something else. This engine would have to be built much different than the street engines I had in my other cars if I was going to be competitive on the track. But it couldn't be an all-out, high-compression race engine if I wanted to cruise around town with my boys. We started with the big picture, then worked our way down to the nitty-gritty.

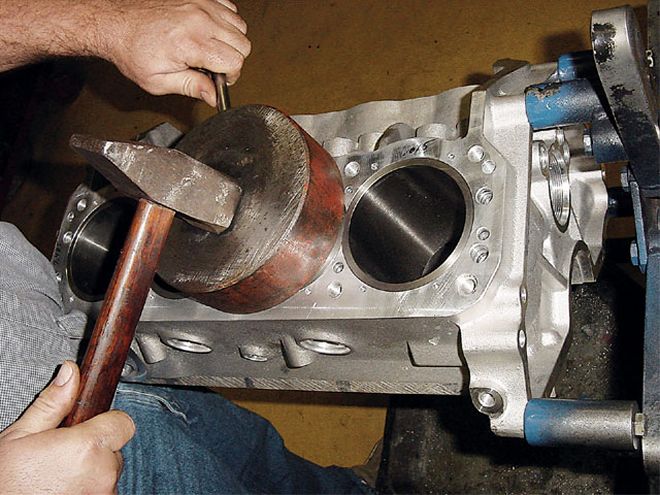

With an aluminum block you must make sure the sleeves are completely seated in the block. One little tap with a big hammer will do the trick every time.

With an aluminum block you must make sure the sleeves are completely seated in the block. One little tap with a big hammer will do the trick every time.

For this engine, weight is critical and space is tight. Lumpy chose an aluminum dry sump Ford SVO 302 block with an 8.7-inch deck height. This will allow us to use a very lightweight 302 rotating assembly and still hit our cubic-inch goal of 380. The rotating assembly began with a billet Scat Ultra Light crank, and then we added Oliver Ultra Light billet connecting rods and custom Diamond Pistons.

With all the parts in hand and the machine work completed, every tolerance was checked and the short-block was assembled. The second major component was the heads. The engine is just an air pump and the heads dictate how much air the engine can potentially flow. To give us great airflow within the range of our cam, we chose SVO Robert Yates racing heads. They are outfitted with Jesel shaft rockers and titanium valves, locks, and retainers. We're using spray bars in the valve covers to keep it all cool.

The cam selection is one of the most important decisions of your build. It will decide how the air flows through your heads. We're using a custom grind from Competition Cams along with their solid roller lifters. When you run Weber carburetors, your cam grind needs some special consideration. I have always heard it is best to keep your overlap under 25 degrees and your duration under 240 degrees at .050 with a lobe separation of 110 degrees or higher.

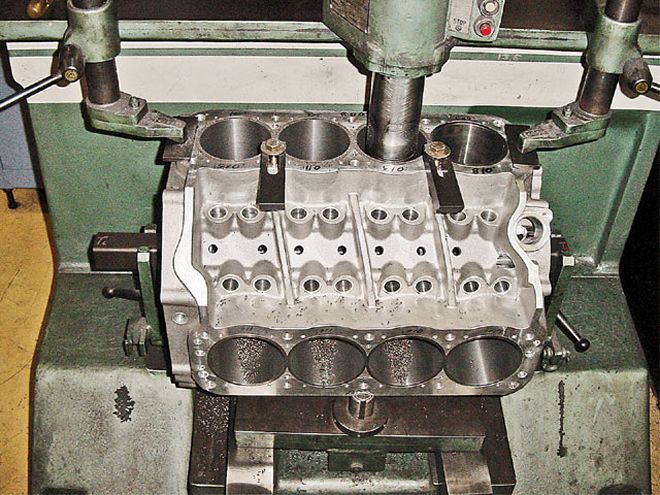

Every new block needs to be decked, honed, bored, and clearanced to meet the specifications of a particular job. We opened up the bores to 4.125-inch.

Every new block needs to be decked, honed, bored, and clearanced to meet the specifications of a particular job. We opened up the bores to 4.125-inch.

When it comes to Weber carburetors, it's a love-hate relationship. They can take a lot of patience to tune correctly, but when they are set they perform like nothing else. In keeping with the vintage look, the Webers were our only option. An intake that fits an 8.7 deck 302 with Yates racing heads is not exactly an off-the-shelf item. Lumpy asked the folks at Price Motorsports to help. They built a custom three-piece intake just for our setup. With the Webers in place, we built the linkage and plumbed the fuel lines.

The dry sump oil system was next. This is a must on a serious road race car. The system is made up of a four-stage Weaver pump, a Peterson oil tank, a custom Aviad dry sump pan, a lot of AN fittings, and a mile of steel-braided line (at least that's what it seems like). This will give us ultimate control of our oiling system and maybe a few more horses!

Keeping with the lightweight theme, we used a McLeod Magnum Forces dual disk clutch. This setup, combined with our very light rotating assembly, will yield a very fast revving engine. We dropped in an MSD pro billet distributor and made the final checks before it went to the dyno room for some final test and tune.

In the dyno room we were not looking for our peak horsepower, but instead a flat torque curve and a smooth climb in horsepower all the way to 7,000 rpm where it starts to peak. It was also amazing how fast the engine can rev.

When the dust settled on the engine build, Lumpy had done more than I had expected when I first approached him with this challenge. He and his crew built a high-revving road race engine that can run on pump gas. It is extremely lightweight and it definitely has the vintage GT 40 look. It can run safely to 8,500 rpm, but has a strong mid-range to pull hard out of the corners. It idles smoothly and starts without trouble. It's all you would want in an all-out race engine and calm enough to run to the Dairy Queen.