One of the main reasons for owning a g-Machine over a stock or Pro Street car is to be able to go fast around corners and curves in addition to straight-line performance. While much attention gets paid to fancy coilover shocks and three-link suspensions, the steering system is often overlooked. With the growth of this build segment, the choices for our cars’ steering systems have never been so vast… or so confusing. What ratio is best? Does it affect bumpsteer? Power or manual? Rack or box? The choices are endless, and they can lead to a mental version of vaporlock where you just don’t know which way to go.

In this story we will look at some of the more popular systems out there, along with their pros and cons.

Follow along and learn how to keep your g-Machine project pointed in the right direction.

Power or Manual Steering

No matter what system you choose, you’ll need to decide whether you want it to be a manual or power-assisted system. Manual steering has long been popular with the drag racing and Pro Street crowd for one simple reason: weight. Getting 20 or 30 pounds off the front of the car is a big deal for a straight-line car and, besides, getting those front skinnies to turn doesn’t take a ton of effort. By ditching the power steering you also gain a few horsepower since the engine no longer has to turn the pump. Again, the small gain is not worth the extra effort every time you have to turn the wheels. With a car that handles, those skinny front tires have now been replaced with wide swaths of rubber that have a significant footprint in contact with the asphalt. All this resistance, especially at low speeds, makes the weight savings of ditching the power steering not worth the hassles of living with the car. Could you do it? Sure. Should you do it? Not in our opinion. Besides, driving a car on a road course is tiring enough without the added effort needed to manhandle your steering wheel back and forth. Drivers of cars defined as Pro Touring or g-Machine worry about weight too, but not at the detriment of overall driving performance.

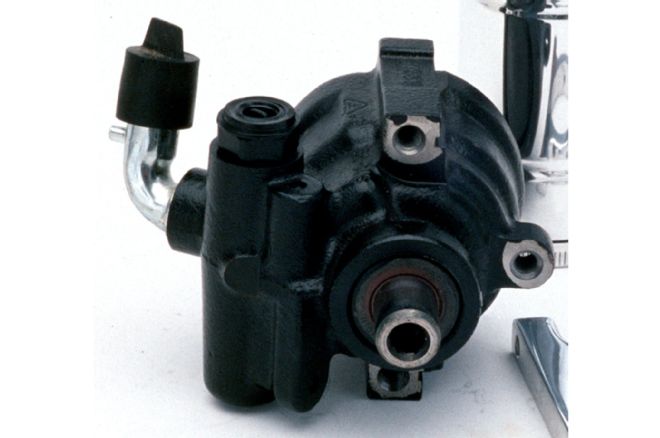

Power-assisted steering systems have a high- and a low-pressure circuit. A power steering pump is turned by a drive belt and pressurizes the fluid going to the gearbox to somewhere between 1,200 and 1,600 psi. The low-pressure line sends fluid back to the power steering reservoir where it is pumped out and sent at high pressure back to the gearbox. It is very important that you keep this in mind when choosing the lines for your system. The low-pressure side is pretty forgiving, but you want to make sure to use the right parts for the high-pressure line. Another good idea is to incorporate some sort of cooler for your power steering fluid. During track use, fluid temps can get well over 200 degrees, and this will affect the performance of your system. In fact, if you are using an older style pump where the reservoir tank is soldered to the pump body, this type of high heat has been known to cause the parts to separate, throwing fluid all over your hot engine bay and onto the track. Not good at all. Remote reservoirs are one way around this problem, or you could use a modern unit with an integrated non-soldered or plastic tank.

Here is an example of an early GM power steering pump. While OK for cruising around, it is not going to hold up to track use. Some other versions of this pump have upper sections of the tank that are soldered to the lower section, and at high temps they can separate; not a good thing.

Here is an example of an early GM power steering pump. While OK for cruising around, it is not going to hold up to track use. Some other versions of this pump have upper sections of the tank that are soldered to the lower section, and at high temps they can separate; not a good thing.

Flaming River and many other companies offer a variable-rate pump that will hold up to even the toughest use. Fluid is pumped faster at low rpm to make maneuvering easy, and it’s pumped slower at high rpm to give a better feel. This type of pump can use either an integrated or remote reservoir. In this case, this one is set up for the remote version.

Flaming River and many other companies offer a variable-rate pump that will hold up to even the toughest use. Fluid is pumped faster at low rpm to make maneuvering easy, and it’s pumped slower at high rpm to give a better feel. This type of pump can use either an integrated or remote reservoir. In this case, this one is set up for the remote version.

This modern GM Type-II pump from Eddie Motorsports has an integral fluid reservoir that will not be affected by heat. It also has better internals than the old factory pumps. Since the tank is attached to the pump, you have less fluid lines to worry about.

This modern GM Type-II pump from Eddie Motorsports has an integral fluid reservoir that will not be affected by heat. It also has better internals than the old factory pumps. Since the tank is attached to the pump, you have less fluid lines to worry about.

Many companies offer reworked recirculating gearboxes. Several of these companies, like Detroit Speed Inc., will help you pick the box that will best fit your needs. Companies like Flaming River and CPP offer a wide array of gearbox choices to fit whatever project you have in the works. This one from Detroit Speed can be ordered with a ceramic coating to help mitigate heat coming off the headers.

Many companies offer reworked recirculating gearboxes. Several of these companies, like Detroit Speed Inc., will help you pick the box that will best fit your needs. Companies like Flaming River and CPP offer a wide array of gearbox choices to fit whatever project you have in the works. This one from Detroit Speed can be ordered with a ceramic coating to help mitigate heat coming off the headers.

Recirculating-Ball Steering Box

From about 1950 until sometime in the ’80s, recirculating-ball was the standard in steering technology. Since we have already discussed the merits of power-assisted steering, we will assume that is what you are going to run. Steering gearboxes are set up with different ratios that affect how many times you have to turn the steering wheel to get the front wheels to turn lock-to-lock. For example, in a wide-ratio box you may have to turn the steering wheel 4.5 revolutions to get the front wheels to turn lock-to-lock. For a close-ratio steering box with a ratio of 12.7:1 it will only take 3 revolutions of the steering wheel to go lock-to-lock. So, what difference does 1.5 revolutions make? The answer is a lot. You may not notice it that much driving to the grocery store, but on a road or autocross track where you’re constantly throwing your car back and forth through the turns, the wide-ratio box makes you work much harder than the close-ratio box. More work will tire you out sooner and affect your performance. The close-ratio box will also make your car feel more responsive since it will require less driver input to cause your car to maneuver.

In addition to the ratio steering, gearboxes can also be adjusted for the amount of effort, or resistance, you feel when turning the steering wheel. In a car set up with low or no effort, you will have very little feedback through your steering wheel and the car will feel like it is floating around on the road. You need to find a happy medium between low effort when you are moving slow or sitting still and a higher effort setup that would be good at speed. Keep in mind that the diameter of the steering wheel also affects this ratio, or at least how it’s perceived. A smaller wheel will make the ratio seem even quicker, so a small wheel coupled with a fast 12.7:1 steering box might not be the best choice.

There are many companies that offer rebuilt Saginaw 600 gearboxes for your GM application. They have generally been reworked to the close-ratio 12.7:1 and the efforts have been tweaked to a good performance compromise. If you are on a budget you can sometimes find factory close-ratio boxes used in performance models at salvage yards. For example, if you can find a used gearbox from a later-model (late ’70s) Z28 it would bolt directly to your first-gen Camaro and provide a significant improvement for very little cash. Companies like Detroit Speed Inc., CPP, and Flaming River sell brand-new gearboxes in a wide array of choices to fit your Chevy. One company often looked to by racers for their box rebuilds is AGR. AGR completely goes through the box and beefs up the internal parts and seals. They even go so far as to add an additional bearing for extra support. Many of the larger rebuilders also dyno check each gearbox for pressure and balance, as well as being tested for leaks. With all the choices out there it is easy to see why this steering system is so popular.

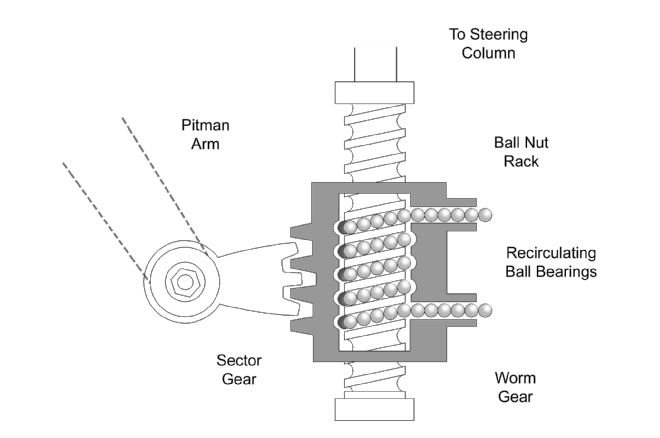

How does a recirculating gearbox work? The recirculating-ball steering box contains a worm gear. You can imagine the gear in two sections. The first section is a block of metal with a threaded hole in it. This block has gear teeth cut into the outside of it that engage a gear that moves the pitman arm back and forth. The steering wheel connects to a threaded rod, similar to a bolt, which sticks into a hole in the block, and when the steering wheel spins, it turns this bolt. Instead of the rod twisting farther into the block the way a regular bolt would, this rod is held fixed so that when it spins it moves the block, which moves the gear that turns the wheels. Rather than have the bolt directly engage the threads in the block, all of the threads are filled with ball bearings that recirculate through the gear as it turns and acts as rolling threads. The balls actually serve two purposes. First, they reduce friction and wear in the gear, and second, they reduce play in the gear. If it wasn’t for this ball bearing design, slop would be felt whenever you changed the direction of the steering wheel. This is because without the bearings in the steering gear, the teeth would come out of contact with each other for a moment, making the steering feel loose and floaty.

There are several advantages to recirculating-ball systems. First, by varying pitman arm length you can easily offer more or less steering travel than a rack-and-pinion system. Second, it is typically less expensive than converting to a rack-and-pinion system, perfect for someone on a budget. This time-tested steering system is very rugged and it is still preferred in racing organizations like NASCAR. Third, this is a very easy-to-install upgrade to your car and is generally a bolt-in deal that will keep your car with a factory look.

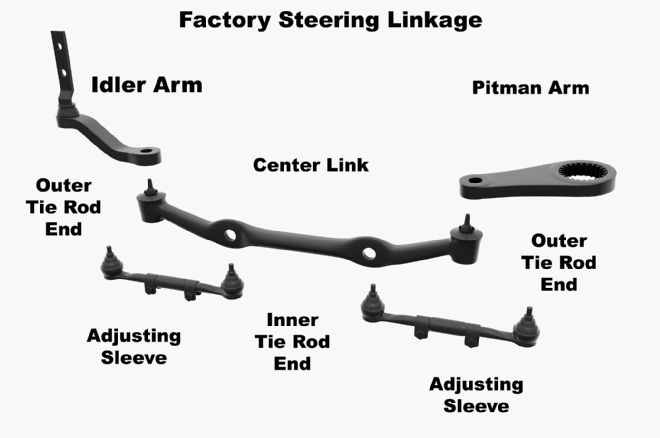

There are also several disadvantages to traditional gear boxes. First, since the box consists of many moving parts, there is quite a bit of friction and many wear points. The design also makes it less efficient than a rack-and-pinion system and it requires more effort. You also need to consider that a gearbox steering system has quite a few more linkage wear points including the inner and outer tie rods, the pitman arm, and the idler arm. Lastly would be weight, even when using the lighter 600 gearbox, the recirculating gearbox-based steering system is quite a bit heavier than the more compact rack-and-pinion system.

Rack-and-Pinion Steering

One of the biggest trends in the Pro Touring and g-Machine segment has been converting cars over to modern rack-and-pinion systems. This is done by either retrofitting an aftermarket rack-and-pinion to an OE subframe or by replacing the entire subframe with an aftermarket one designed to hold a rack-and-pinion unit.

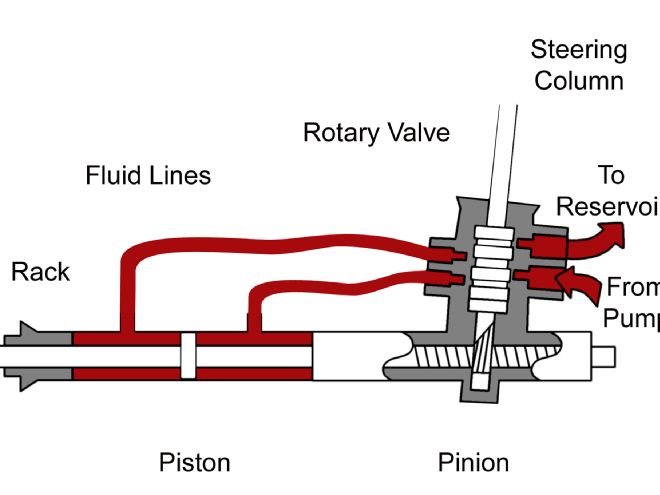

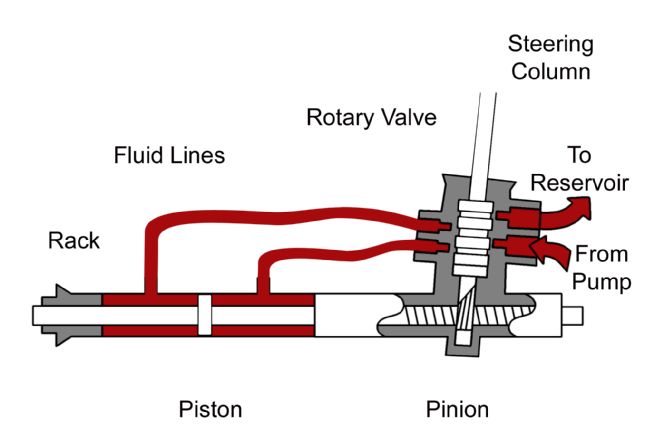

So how does a rack-and-pinion system work? A rack-and-pinion gearset is enclosed in a metal tube with each end of the rack protruding from the tube. The gearset accomplishes two things. First, it converts the rotational motion of the steering wheel into a linear motion needed to turn the front wheels, and secondly, the gearset provides gear reduction, which lessens the effort needed to turn the wheels. A rod called a tie rod connects to each end of the rack. The pinion gear is attached to the steering shaft. When you turn the steering wheel, the pinion gear spins, moving the rack. The tie rod at each end of the rack connects to the steering arm on the spindle. On a power system, part of the rack contains a cylinder with a piston in the middle and this piston is connected to the rack. There are two fluid ports on the rack; one on either side of the piston. Supplying higher-pressure fluid to one side of the piston forces the piston to move, which in turn moves the rack providing the power assist.

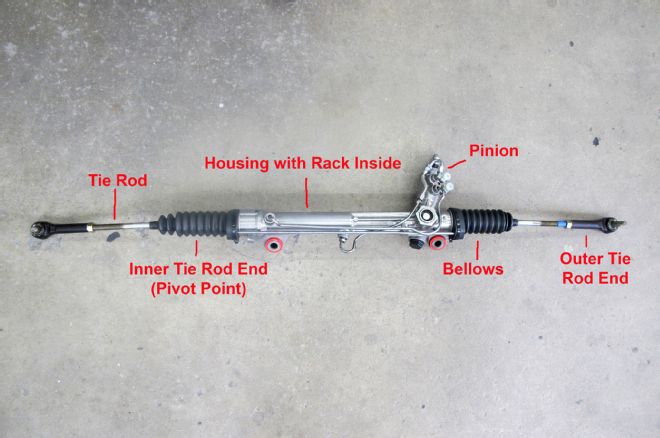

Advantages of the rack-and-pinion systems are many. First is its simplicity. With only two moving parts there is not only less friction, but the positive engagement of the system gives a very tight and responsive feel to the steering. Secondly, the complete system has only four wear points in the linkage: the inner ball joints and outer tie-rod ends. This simplicity and lower number of parts is one reason why most new cars use rack-and-pinion. Third, a rack-and-pinion system is quite a bit lighter than a traditional box system. Less weight off the front of the car is always a good thing to strive for. Fourth, because of its design you often gain added clearance for headers and the rack-and-pinion is sometimes easier to package into the car.

Every option in life has drawbacks and rack-and-pinion is no exception. Due to the limitations on the number of teeth that can be cut into the rack, there is typically less travel available compared to a recirculating-ball system. Another thing to consider is that a rack-and-pinion system will require quite a bit of work to retrofit into an older car. In some cases you will have to notch the frame and relocate the sway bar. You will also have to calculate the geometry so that you don’t end up with poor handling due to bumpsteer and a host of other issues. If you are buying an aftermarket front subframe you may have no choice but to go with a rack-and-pinion setup, especially if it was designed to accommodate it. Some companies, like Unisteer, offer rack-and-pinion systems that have been re-engineered for specific retrofit applications onto stock subframes. While more expensive than the do-it-yourself option, the Unisteer racks are much easier to install and are more geometrically correct since they were designed to help limit issues like bumpsteer. Lastly, a rack-and-pinion system, especially in kit form, will make your wallet quite a bit lighter than tossing in a rebuilt close-ratio box.

In this simplified drawing of a recirculating-ball steering system you can see how the rotational energy of the steering column is turned into the linear movement of the pitman arm. – Drawing by Kris Horton.

In this simplified drawing of a recirculating-ball steering system you can see how the rotational energy of the steering column is turned into the linear movement of the pitman arm. – Drawing by Kris Horton.

Here are the common steering parts used with a recirculating-ball steering gearbox-based system. The number of parts is one reason this system is heavier than a rack-and-pinion steering system. However, it is also stronger. You can also see that there are more wear points compared to a rack-and-pinion steering system. Note that this diagram does not even include the gearbox.

Here are the common steering parts used with a recirculating-ball steering gearbox-based system. The number of parts is one reason this system is heavier than a rack-and-pinion steering system. However, it is also stronger. You can also see that there are more wear points compared to a rack-and-pinion steering system. Note that this diagram does not even include the gearbox.

Here you can see how a power rack-and-pinion system works internally. Turning the steering wheel activates a rotary valve and sends high-pressure fluid to the appropriate side of the piston to assist in turning. – Drawing by Kris Horton.

Here you can see how a power rack-and-pinion system works internally. Turning the steering wheel activates a rotary valve and sends high-pressure fluid to the appropriate side of the piston to assist in turning. – Drawing by Kris Horton.

Behold the simplicity of the rack-and-pinion system. While not as sturdy as a traditional steering system, it is light and responsive. In this configuration there are four wear points. This picture is of a manual rack, whereas a power-assisted rack would have fittings for the fluid lines. When retrofitting this into an older car you must be careful to end up with proper steering geometry.

Behold the simplicity of the rack-and-pinion system. While not as sturdy as a traditional steering system, it is light and responsive. In this configuration there are four wear points. This picture is of a manual rack, whereas a power-assisted rack would have fittings for the fluid lines. When retrofitting this into an older car you must be careful to end up with proper steering geometry.

The Bottom Line

According to Tristan Statler at Unisteer, “In general, when considering the option of a steering box versus a rack-and-pinion, one must always remember that either system will only perform as well as it is designed and built for its particular application. A poorly designed steering box setup may not function as well as a rack-and-pinion setup, and vice versa.” You need to think about how you plan on using your car. If your car will never see the track, then you might not need to run a power steering cooler or have to worry about using the older soldered pumps. If you plan on serious track time, then a company like AGR should be able to set you up with some higher-end “race grade” steering parts, which is their specialty.

Whichever way you go, it is important that you ask the right questions of the various vendors and explain to them how you will be using your car. Through proper parts selection you will end up with a steering system that will make your ride much nicer to drive.