In previous stories about our Project Slick Challenger, a 1973 Dodge Challenger Rallye 340, four-speed, we mentioned it was being built to be a fun street driver that'll be competitive with modern muscle cars. We don't want a wallowing, worn-out suspension hampering us while motoring along with today's better-handling cars and crazy drivers. After learning that QA1 developed a modular K-member suspension system with much more strength than stock, space for headers and oil pans, and improved handling, plus allowed us to keep the factory torsion bars, we said, "sign us up!"

We don’t want a wallowing, worn-out suspension hampering us while motoring along with today’s better-handling cars…

What's especially nice is the fact that QA1 designed its tubular K-member and corresponding suspension parts to interchange with its OEM counterparts. This enables you to build your front suspension as you need and can afford. If someone wants to start out with a pair of upper or lower control arms, a K-member or the Dynamic Strut Bars, they can do so in whatever order they want. There's no need to buy everything at once as with other suspension systems that only work with specific components such as coilover shocks, steering racks, spindles, brakes, and more. Those other additional parts will significantly add up the cost.

…QA1 designed its tubular K-member and corresponding suspension parts to interchange with its OEM counterparts.

The strong and spacious QA1 K-member ('70-74 E-Body, '71-72 B-Body PN 52314, MSRP $694.95) is also available for the '67-72 A-Body and the '66-70 B-Body, all at the same price. Why waste your time and money repairing the stock trouble-prone K-member? Your author remembers back in the '70s and '80s a good friend who owned a nearby suspension shop regularly repairing and reinforcing the cracked, flexing, problematic factory K-member. The new QA1 unit resists deflection to a far greater degree, which will provide some much-needed chassis rigidity. Note: QA1 beefed up the trouble-spot pivot tube area for the LCA pivot shaft (where it goes into the K-frame), which has plagued Mopar owners for years. QA1 designed the E-Body and the '66-70 B-Body K-member to use a stiffer E-Body sway bar. For now we'll refinish and reuse the stock 7/8-inch sway bar, along with new poly bushings.

The new QA1 unit resists deflection to a far greater degree, which will provide some much-needed chassis rigidity.

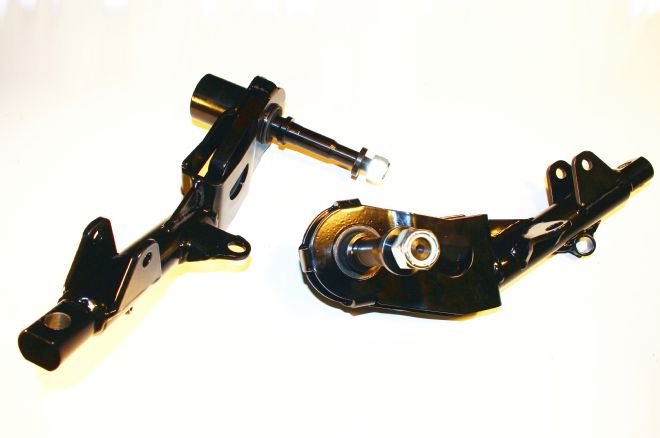

The new tubular control arms that QA1 has created will add 3 to 4 degrees of caster and 0.5 to 1 degree of negative camber to banish wander while increasing front-end grip for added traction. The upper control arms (PN 52305, MSRP $349.95) feature polyurethane bushings with grease fittings and low-friction ball joints. Down below, the lower control arms (PN 52308, MSRP $449.95) come complete with new pivot shafts and bushings already installed. Through the years we've replaced bushings, pivot shafts, and ball joints on the stock stamped-steel control arms—it's just not worth the hassle and time, plus most don't have the facility or equipment (press, welder, paint, materials, and more) to repair and reinforce them. These new tubular arms offer far more structural integrity and geometry to enable your old Mopar to become a road-hugging machine.

When investigating QA1's new suspension components, we noticed it offers new torsion bar adjusters (PN 52360 MSRP $99.95), eccentric camber bolt adjusters (PN 52361 MSRP $34.95) and heavy-duty 9/16-inch tie-rod adjusting sleeves (PN 52325 MSRP $47.76). Your factory 40-plus-year-old parts are often not reusable. Usually they are broken, stripped, or fatigued beyond safe reuse. For safety's sake, we ordered these new key components to replace the beat-to-death originals. Also, they will ease adjusting the ride height and performing the front end alignment.

QA1's stronger K-member is innovative, but so are their replacement strut rods, which QA1 refers to as dynamic strut bars (PN 52312 MSRP 219.95). These thicker/stronger strut bars minimize deflection under hard braking and lateral load. Their unique feature is they pivot on the exact axis as the lower control arm during suspension travel. Its robust rod end provides bind-free pivoting action that allows more positive control arm travel. The stock strut rods were notorious for premature bushing wear due to the binding (pushing and pulling) that conflicts with LCA travel.

In the past we have strip and skidpad-tested QA1 Stocker Star shocks using a '67 Coronet R/T test mule and found them to be a huge improvement over stock. These proven dampers lowered the 60-foot e.t. and dramatically increased the road-holding ability by keeping the tires safely planted to the road surface. These units will make a night-and-day difference in roadworthiness. For our E-Body, we simply ordered the single-adjustable units (Front TS501, Rear TS901, MSRP $167.95 each). If your intention is serious autocross or road course action, the QA1 double-adjustable Stocker Star shocks offer individual tuning for compression and rebound settings in different road or track conditions.

We are looking forward to driving a more composed car once we implant the 577hp LA engine. With that done, the Slick Challenger will be able walk away from late-model muscle cars—even through the turns. Now check out how easy it is to swap out those trouble-prone components using only a floor jack, jackstands, and handtools.

1. QA1's new, stronger-than-stock tubular K-member is just what many of us have long awaited—a K-frame that allows us to keep our beloved torsion-bar suspension. It's designed to accept and interchange with both OEM and QA1 components. This unit has additional strength and stiffness to resist deflection to a far greater degree, which adds chassis rigidity.

2. We opted to replace the stock stamped-steel LCAs with QA1 tubular units. Their tubular construction offers greater rigidity without increased weight. Already installed are new bushings and pivot shafts that'll save you time and hassle. The T-bar, strut rod, shock, sway bar, eccentric adjuster and ball joint locations correspond to the stock positions for easy interchange from OEM.

3. This is a typical dry-rotted LCA bushing. Through testing, QA1 found rubber bushings will hold up better to the pivoting, twisting action of the LCA and pivot shaft. QA1 noted that harder polyurethane bushings will rip and tear more easily, plus the driver will feel more road imperfections that can resonate through the K-frame and body.

4. QA1's stronger tubular upper control arms add most of the revised geometry. They will add 3 to 4 degrees of caster and up to 1 degree of camber for improved vehicle control. Their bushings are made from tough polyurethane for minimal deflection. Easy-to-access zerk fittings provide lube for long life with smooth and easy motion. Another time saver is that the ball joints are preinstalled.

5. This dry-rotted rubber bushing (right) is 27 years old and has less than 1,000 miles on it since being replaced on this garage-kept car. If we could look 27 years into the future with the same conditions, the QA1 upper control arm bushing would still look and perform like new.

6. QA1's dynamic strut bar (bottom) resists deflection under hard braking and cornering better than a stock strut rod. Adjustment points at both ends allow easy in-car tuning. Aluminum construction makes the bar lighter than stock for less unsprung weight. The bar's most unique feature is its robust rod end. It allows bind-free suspension movement of the LCA, unlike the stock strut rod that tears up its bushings.

7. To ease ride height and alignment adjustments we ordered these key components (heavy-duty tie-rod sleeves, camber bolt adjusters, and torsion bar adjusters). They are made from high-strength alloy steel and are zinc-plated for extra durability.

8. QA1's adjustable Stocker Star shocks are a favorite among racers. These dampers will improve handling and road holding in any Mopar muscle machine. The easy access knob will give your suspension the adjustability (in 18 settings) you'll want to fine-tune your ride.

9. Here's a front view of the LCA pivot tube on the QA1 K-member. The weak link of the factory K-member is the thin pivot tube and surrounding area. The pivot tube would break loose and bounce around causing havoc to the K-member and LCA. No fear, QA1 addressed this problem by installing double-thick pivot tubes with thick welding around both the front and rear tube ends.

10. This is a front view of the stock pivot tube area without any welding on the stock K-frame of our project car. It appears the thinner pivot tube presses against the inside of the frame when the pivot shaft bolt and washer is torqued to 145 ft-lb.

11. Many years ago, a repair job to reinforce the right rear pivot tube area was performed on our factory K-member. Apparently someone welded a thick washer to the pivot tube and frame. All Mopar T-bar K-members need to have their LCA pivot tubes inspected for loosening and cracking. If defective, they need to be properly reinforced. Or just replace the factory unit with the stronger QA1 K-frame.

12. We chose to build the K-frame assembly on the garage floor rather than on the car. Don't torque the rear nuts for the dynamic strut bars and the pivot shaft nuts for the LCAs until the car is at full rest weight and ride height. Once the front mount of the DSB is indexed and there is no binding with full movement of the LCA, the front mount can be tightened to 42 ft-lb.

13. Working solo, the unit went in with little fanfare. A floor jack easily put the K-member into position to start the four supplied bolts. We left the bolts loose for enough K-frame movement to ease installation of our new Firm Feel steering box (the original box exhibited 4 inches of steering wheel lash). Once the new steering box was installed, the four K-member bolts were tightened to 125 lb-ft.

14. A little grease on both ends of the bushings and a light tap from a mallet are all that's needed to install the upper control arm. Then, the new camber bolt adjusters were installed in the same orientation as the originals. We'll leave the bolts lightly seated until the front end is aligned.

15. It's easiest to install the lower ball joint to the LCA before the spindle is attached. The ball joint castle nut received 85 ft-lb of torque. We purchased new Moog steering and suspension components (lower ball joints, pitman and idler arm, inner and outer tie rod ends) from our local parts jobber to replace the worn-out originals.

16. Next the spindle was attached to the ball joints of the UCA and LCA. Be sure to reuse the original lower-ball-joint-to-spindle fasteners (fingers touching). These two specific nuts and bolts are special with reduced heads to allow no interference with operation of the brakes and steering. Tightening for the upper-ball-joint-to-spindle nut is 100 ft-lb. The original lower-ball-joint-to-spindle fasteners receive 120 ft-lb of torque.

17. At this point our new K-member and suspension components were completely installed. Here we are tightening the original shock bolt and nut that we reused for the new QA1 Stocker Star shocks. Notice the rebuilt FFI steering box and new pitman arm in place with only the steering linkage and original T-bars left to hook up.

18 & 19. When comparing the before and after, it's easy to understand why we love the new tubular look! Being able to keep the torsion bars is a big plus to many of us. Kudos to QA1 for updating and strengthened the K-member and suspension components for the traditional Mopar enthusiast. As an aside, a host of Eastwood products were used to refinish the engine bay before beginning the QA1 installation. We'll be back with driver feedback once we drop-in the 416ci LA engine and get the Slick Challenger out on the road!