Classic Mopars were considered ahead of their time in many ways, thanks to superb engineering and a dedication by the Chrysler Corporation to building the best performance cars of the muscle car era. Compared to other manufacturers of the time, Chrysler excelled in areas like the power of their engines, and the durability of components like their four-speed and TorqueFlite transmissions, and the 8¾ and Dana 60 rear differentials. Another area that really set Chrysler apart, and enhanced the performance of Mopar vehicles, was the suspension. Up front, torsion bars not only provided straight tracking and a smooth ride, but also offered adjustable ride height and the ability to adjust the corner weights of the vehicle. In the rear, multi-leaf springs were used to support the vehicle, and along with a pinion-snubber, the Chrysler leaf spring suspension offered great handling, a nice ride, and the ability to really plant the rear tires during hard launches.

The leaf spring suspension is nothing new. In fact, leaf springs have been utilized for vehicle suspensions since cars and trucks were first produced. In fact, they’re still used in many applications today. In some applications, such as straight axle or four-wheel drive vehicles, leaf springs were (and are) used in the front as well. For the purposes of this article, however, we’ll concentrate on Mopar rear suspension, specifically the leaf springs and their associated components.

01 The leaf spring suspension is nothing new, as automobiles and trucks have used leaf springs since their inception and still do even today. Mopar muscle cars had some of the best leaf spring rear suspensions available, but there are still ways to make this type of suspension better. "> <strong>01</strong> The leaf spring suspension is nothing new, as automobiles and trucks have used leaf springs since their inception and still do even today. Mopar muscle cars had some of the best leaf spring rear suspensions available, but there are still ways to make this type of suspension better.

<strong>01</strong> The leaf spring suspension is nothing new, as automobiles and trucks have used leaf springs since their inception and still do even today. Mopar muscle cars had some of the best leaf spring rear suspensions available, but there are still ways to make this type of suspension better.

Mopar almost exclusively used leaf springs in the rear of their vehicles, unlike other manufacturers who used coil springs in their suspensions. The springs of any suspension, whether leaf, coil, or otherwise, serve the function of absorbing irregularities in the road as well as supporting the chassis of the vehicle. In addition to absorbing road irregularities and supporting the weight of the vehicle, leaf springs also serve to locate the rear differential housing both from side to side and front to rear. In terms of performance, leaf springs have some advantages over other types of springs, but there are also some downsides to leaf springs.

When used in a street car application, multi-leaf springs like those installed in Chrysler products offer a smooth ride, combined with good acceleration characteristics. The part of the leaf spring in front of the differential housing acts more like a locator, and the part of the spring behind the housing provides more of the spring function of the leaf spring. Under hard acceleration, the differential housing tries to rotate the opposite direction of the tires (pinion goes up), due to simple physics. From basic science class, we remember that for every action, there is an equal and opposite reaction. In common suspension and racing terms, this anomaly is called axle wind up, or wrap up. The terms “axle wind up” and “axle wrap up” mean the same thing, and can be used interchangeably. “Spring wind up” is also a commonly used term to describe the same action, occurring when the front section of the spring distorts, allowing axle wrap up.

Pinion-Snubber

Knowing axle wind up is counter-productive to both the car’s acceleration and the durability and performance of the leaf spring, Chrysler engineers came up with an easy fix by installing a part called a pinion-snubber. The pinion snubber bolts to the top of the differential in the area of the pinion yoke, and when the axle housing tries to “wrap up,” the snubber engages the car's floor, and prevents the axle wrap up from occurring. Since the snubber tries to lift the car at this point, the rear differential is actually forced downward and improves rear traction. For this reason, we recommend that the pinion snubber never be removed from stock suspension, and in many cases either modifying the stock snubber or installing an aftermarket adjustable snubber can improve traction. Stock pinion-snubbers can be as much as 3-4 inches from the car’s floorboard, allowing the axle to wrap up quite a bit before the snubber hits the floor. By moving the snubber closer to the floor, by shimming or modifying the stock snubber, or by installing an adjustable pinion-snubber, axle wrap up is reduced and traction is improved. In performance applications, we recommend adjusting the pinion snubber to be no more than an 11⁄2-inches from the floor for maximum traction, but if you regularly carry rear-seat passengers or a bunch of heavy items in your trunk, this may cause the snubber to engage the floor during normal driving. Of course leaf spring rate has something to do with this, and stiffer performance style (higher rate) springs will move less when the car is loaded, so the pinion snubber can be positioned closer to the car’s floor.

Super Stock Springs

Even with a pinion snubber installed and adjusted properly, the forward section of leaf springs still have a tendency to wrap up in high-torque applications. This is why Chrysler installed heavier-rate springs on cars equipped with performance engines, and why these springs are biased to where the leaves focus more towards the front of the spring, in front of the differential housing. The best example of this is found in the Super Stock leaf springs, which were developed for the Hemi-powered A-Body Barracudas and Darts. Essentially, the front half of Super Stock leaf springs are supported (clamped) more than a typical leaf spring, so that it will reduce spring wind up.

While only available from the factory on the specialized Dart and Barracuda race cars, Mopar Performance offers Super Stock springs in a variety of spring rates, through their catalog, dealer network, or a variety of aftermarket suppliers such as Summit Racing Equipment. A downside of the Super Stock springs is that they are only made in the A-Body length. But, by installing front hangers with different dimensions, the Super Stock springs can be installed on B- and E-Body Mopars as well. AR Engineering specializes in front spring hangers and reinforcing brackets, and has hangers available to adapt the Super Stock leaf springs to all popular Mopar body styles.

With high torque and sticky tires, axle wind up (actually spring wind up) can still occur even with Super Stock leaf springs installed and a properly adjusted pinion-snubber. In this situation, the forward section of the leaf spring itself actually distorts, bending upward in an S-shape, allowing the axle to rotate. There is still another trick you can perform to help eliminate spring wind up of this type, and it involves installing clamps on the forward section of each leaf spring. By adding either bolted on clamps, or by wrapping red-hot mild steel around the leaves, just behind the leading edge of the lower leaf, distortion will be minimized and axle wrap up reduced significantly.

Pinion Angle

Pinion angle is also an important part of rear suspension setup, and the ideal pinion angle can vary from application to application. The idea here is to have enough positive angle (pinion angled toward ground when compared to the driveshaft), so that when the axle wraps up, the pinion gear and the driveshaft are at a neutral, or zero angle. In four-link cars, the necessary pinion angle can be as little as one or two degrees, in ladder bar cars, four to five degrees is a good starting point. For a leaf-spring application, we’ve seen as much as eight to ten degrees of pinion angle necessary for proper driveshaft alignment under power. The best advice here is trial and error, and for more reading regarding pinion angle and other aspects of rear suspension setup we recommend the book Doorslammers: The Chassis Book by Dave Morgan.

CalTracs

While factory Chrysler leaf spring rear suspensions work very well in both street and performance applications, modern technology has taken leaf spring rear suspensions a step further in recent years. Calvert Racing has upgraded suspension components in the form of their CalTracs traction bars that can be used with factory style multi-leaf rear springs, or with Calvert Racing’s split mono-leaf leaf springs. The function of the CalTracs is essentially the same as the pinion snubber, to eliminate axle wind up, but the CalTracs do a much more efficient job. By using pivot assemblies at the forward spring hanger, and adjustable link bars between the forward hanger and the shock mount under the differential, axle wind up force is transferred to the top of the forward section of the leaf spring, preventing it from distorting.

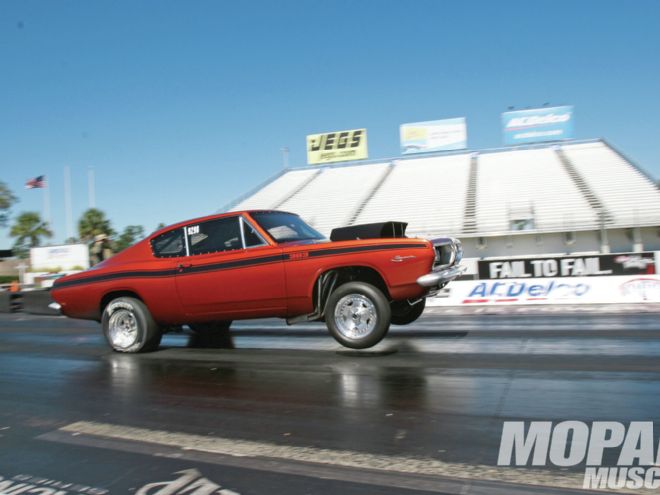

We have used the CalTracs system both with stock springs and with the Calvert split mono-leaf springs, and found the CalTracs setup to be very effective. Installing CalTracs on our B3 project resulted in harder launches, higher wheel-stands, improved 60-foot times, and reduced elapsed times. To see a full installation of the CalTracs rear suspension on our ’64 Dodge Nostalgia Super Stock project, check out the August 2013 issue of Mopar Muscle. The CalTracs system is simple to install, easy to adjust, and adaptable to applications from mild street cars to 7-second outlaw drag cars.

Other Considerations

A car’s rear shocks, front suspension, and overall chassis stiffness, also greatly affects how the car will perform on the street and the track. 50/50 ratio rear shocks are the best all-around choice for the rear, and adjustable or double-adjustable rear shocks allow adjustments for differing track and road conditions. Most Mopars are nose heavy, and in straight-line applications such as drag racing, a Mopar will benefit from getting the front of the car up in the air, transferring the cars weight to the rear tires. Lighter rate torsion bars will allow easier front end travel, as will eliminating or disconnecting the front sway bar if so equipped.

The best way to enhance weight transfer is by installing 90/10 or adjustable race shocks (adjusted for easy extension and hard compression), in the front suspension. A 90/10 shock allows light force to extend the shock (only 10 percent of total force) and heavy force to compress the shock (90 percent of total force), allowing the front of the car to rise, and then stay there keeping more weight on the rear tires. We’ll get more in depth with front suspensions in a future issue of Mopar Muscle.

Chassis stiffness is another consideration in the overall performance of your car, and items like subframe connectors, torque boxes, and a roll cage can affect your suspension in a positive way. The less a car flexes, the more the suspension can do what it’s supposed to. Subframe connectors are available in bolt-in style, or can be welded in place. For the best stiffening, frame connectors from US Car Tool are form fitted and welded to the car’s floor, creating a complete box frame section. In extreme applications a roll bar, or roll cage, will tie the chassis together offering overall stiffness to the suspension and safety to the driver.