William C. Durant, cofounder of Chevrolet, developed the Bow Tie logo in 1913. There have been a number of sources given for Durant's inspiration to create the iconic emblem, including a wallpaper pattern, coal advertisements, and even the flag of Louis Chevrolet's birthplace, Switzerland. But regardless of what inspired it, the cars displaying that well-known badge have always appealed to the general public.

Chevrolets have a loyal following among street rodders as well, but those early offerings wearing a Bow Tie can be challenging to build for two reasons. Prior to 1937 the bodies used wood for structural support, which normally requires extensive repair or total replacement. The second issue is with the frames from 1936 to 1954. The two-piece 'rails for Chevy frames were made from lengths of inverted U-shaped sheetmetal with flanges that were riveted to heavier flat material to form what is essentially a tube. The upper sections or “top hat” portions were quite thin so all the major chassis components were attached to the heavier bottom flanges of the frame—and therein lies the problem. Clipping these frames, or adding suspension components that weld to the upper portions of these 'rails, can be difficult to do properly and cracking or tearing of the thin material often results. The best method is to attach new suspension components to the bottom flanges, just the way Chevrolet did it.

Someone who knows how Chevrolet did just about everything is Ron Wise. A true connoisseur of the Bow Tie brand, his collection ranges from a National Vintage Chevrolet Club Best of Show 1941 Cabriolet to a sliced and diced, Vette-suspended, ZR1-powered 1941 sedan delivery. He's also the proprietor of Chevs of the 40's, which specializes in 1937-54 Chevrolet cars and trucks (and check out Wise's Street Rod Headquarters at streetrodhq.com).

One of Wise's newest products is a bolt-in C5/6 Corvette independent front suspension system for 1939-48 Chevys (a 1949-54 kit to follow, and for truck fans a weld-in C4 kit is available). This Vette conversion is so simple it can be done in an afternoon. With the old suspension removed the new cradle and upper mounts bolt to the strongest part of the frame, the flanges, just as Chevrolet planned it. The Vette suspension's original geometry has been retained, although the track width has been reduced to an early fender-friendly 57 inches, which allows for plenty of rubber on the road. A new narrowed rack is included to match the reduced tread dimension and for ease of steering shaft installation the rack can be rotated in its mounts.

While the benefits of this Vette-based suspension won't come as a surprise, the cost most likely will. The complete conversion kit retails for $3,900 and that includes a narrowed rack-and-pinion, all-new Corvette aluminum suspension components, spindles, rotors, and calipers—all straight from GM's parts bins. The only parts not included are the suspension units and either coilovers or ShockWaves can be used. For those who want to source their own suspension parts the cradle assembly is available for $895 and the required narrowed rack for $240.

So, if the question is how to make an early Chevy a pleasure to drive, the answer is simple enough: Chevs of the 40's new affordable Corvette suspension conversion.

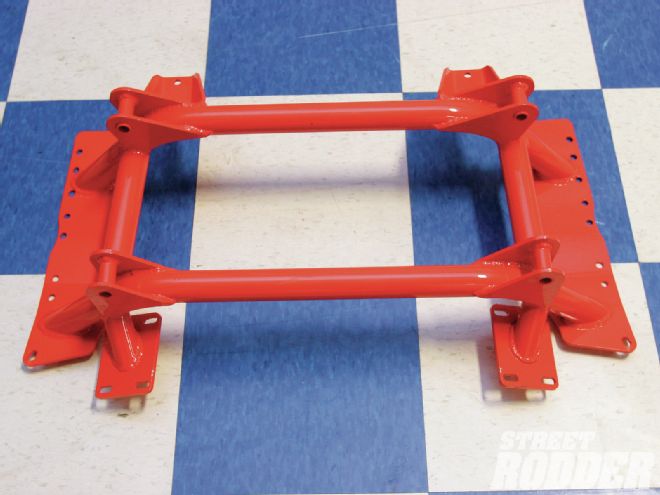

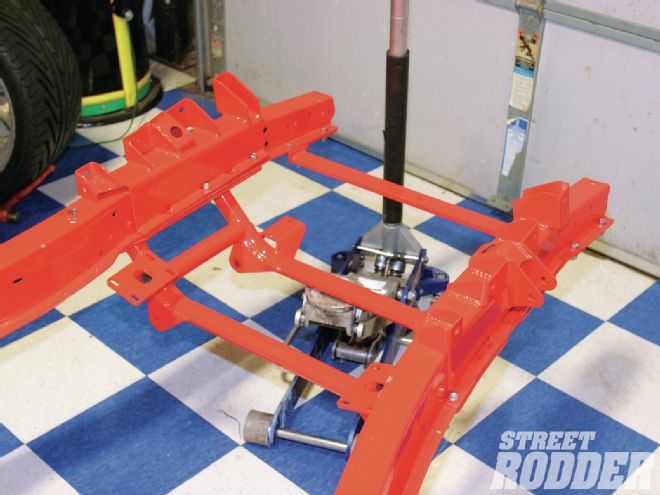

1. This is a bottom side view of the bolt-in lower crossmember. It fits against the flanges of the top hat framerails.

1. This is a bottom side view of the bolt-in lower crossmember. It fits against the flanges of the top hat framerails.

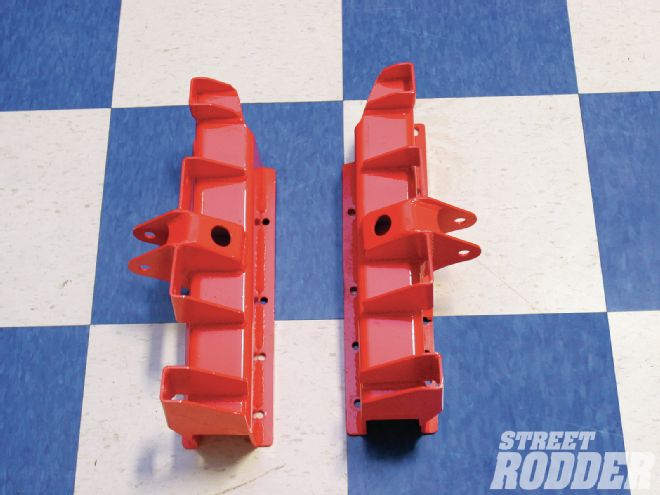

2. These are the brackets the upper A-frames and suspension units attach to. They bolt to the framerail flanges and the lower crossmember.

2. These are the brackets the upper A-frames and suspension units attach to. They bolt to the framerail flanges and the lower crossmember.

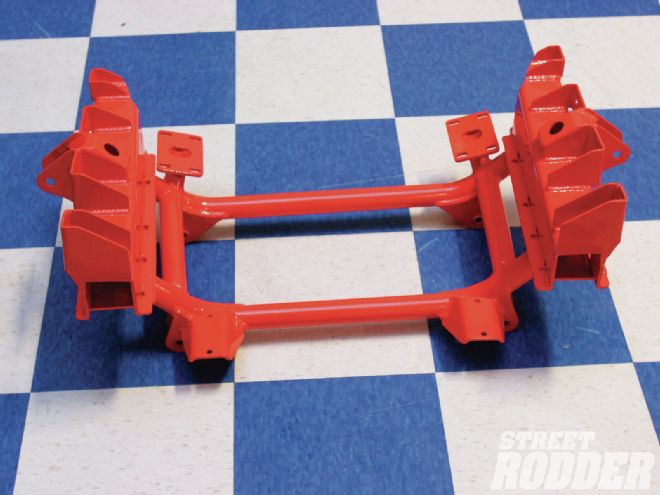

3. This is the assembled crossmember kit. Motor mount brackets for small- and big-block Chevys are part of the package and LS adapters are offered.

3. This is the assembled crossmember kit. Motor mount brackets for small- and big-block Chevys are part of the package and LS adapters are offered.

4. The steering rack (shown with the input shaft pointing forward rather than to the rear as it installs) is narrowed to accommodate the reduced tread width.

4. The steering rack (shown with the input shaft pointing forward rather than to the rear as it installs) is narrowed to accommodate the reduced tread width.

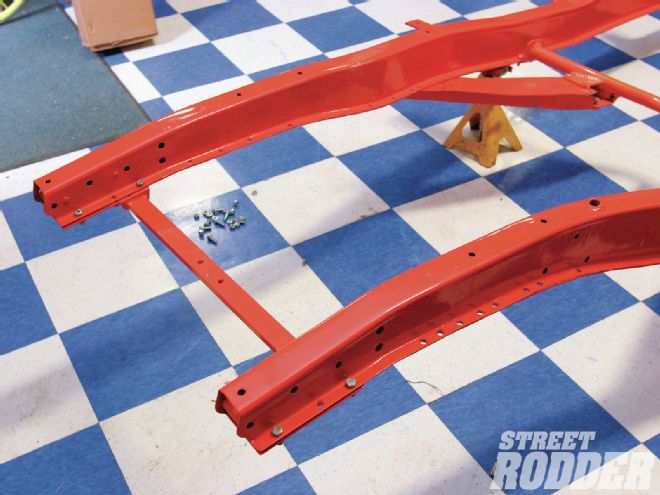

5. Typical of 1936-54 Chevy frames, the upper portion is an inverted U shape with flanges that rivet to a stouter flat material. The existing holes in the flanges are used to attach the new Chevs of the 40’s crossmember.

5. Typical of 1936-54 Chevy frames, the upper portion is an inverted U shape with flanges that rivet to a stouter flat material. The existing holes in the flanges are used to attach the new Chevs of the 40’s crossmember.

6. Mark Bruce and Eric Coberly put the lower crossmember in place. This particular chassis will be going under the very trick ’41 sedan delivery being built by Chevs of the 40’s owner Ron Wise.

6. Mark Bruce and Eric Coberly put the lower crossmember in place. This particular chassis will be going under the very trick ’41 sedan delivery being built by Chevs of the 40’s owner Ron Wise.

7. With the lower portion of the crossmember held in place the upper suspension mounts are slipped over the stock ’rails.

7. With the lower portion of the crossmember held in place the upper suspension mounts are slipped over the stock ’rails.

8. As the holes in the upper mounts and the crossmember are pre-drilled, alignment is automatic. Note the trans crossmember that is available separately.

8. As the holes in the upper mounts and the crossmember are pre-drilled, alignment is automatic. Note the trans crossmember that is available separately.

9. When secured with the included hardware the top brackets and the crossmember sandwich the frame’s flanges, which are the strongest portion of the ’rails.

9. When secured with the included hardware the top brackets and the crossmember sandwich the frame’s flanges, which are the strongest portion of the ’rails.

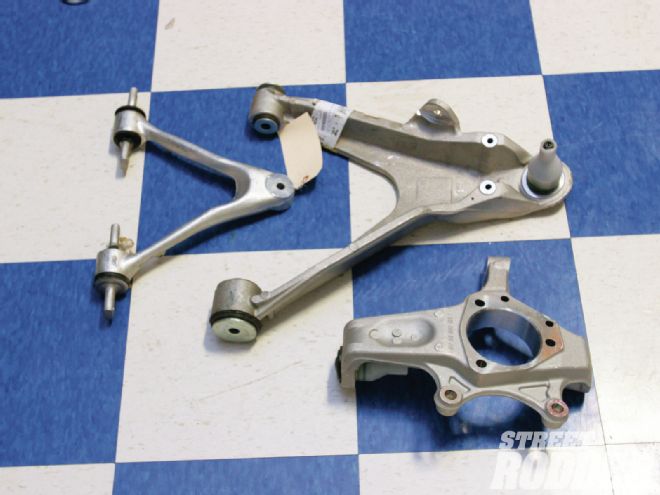

10. For those who don’t have Corvette suspension components handy, Chevs of the 40’s includes them in the complete kit.

10. For those who don’t have Corvette suspension components handy, Chevs of the 40’s includes them in the complete kit.

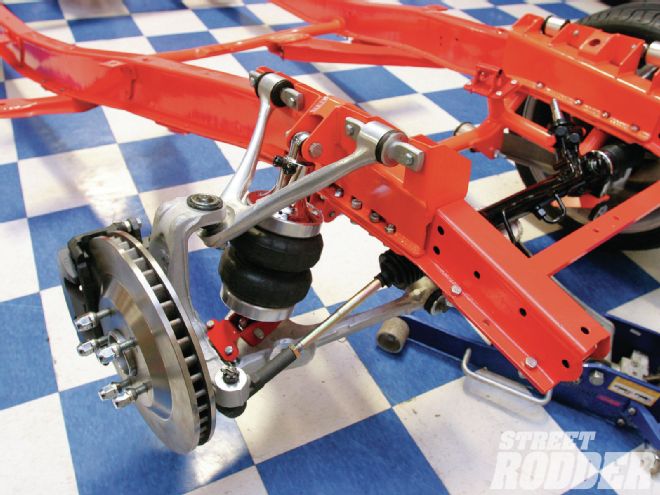

11. Suspension options include ShockWaves...

11. Suspension options include ShockWaves...

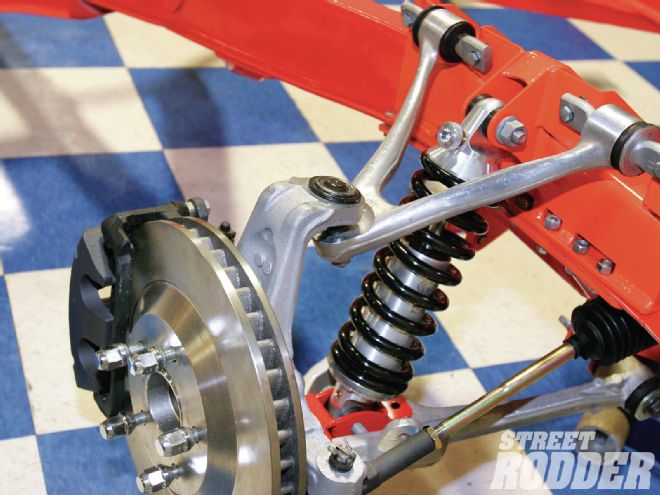

12. ...or coilovers.

12. ...or coilovers.

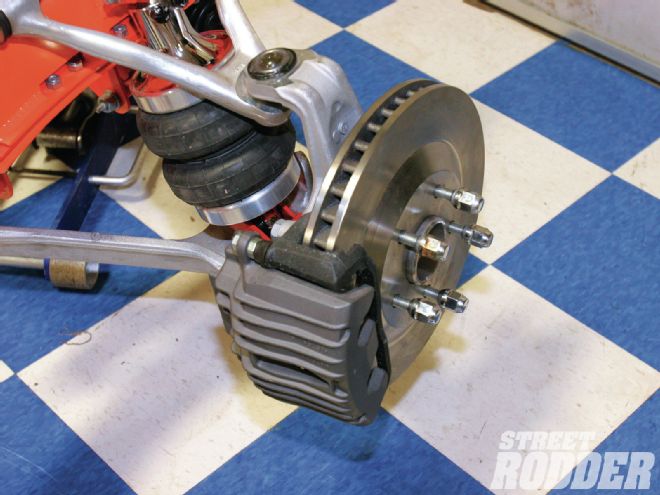

13. Stock Corvette calipers and rotors supply plenty of stopping power.

13. Stock Corvette calipers and rotors supply plenty of stopping power.

14. Up front the minimum wheel diameter is 17 inches, and 4-inch backspacing is recommended.

14. Up front the minimum wheel diameter is 17 inches, and 4-inch backspacing is recommended.

15. Wise’s sedan delivery will be shod with very aggressive 275/35R18s on Forgeline wheels. The deep backspacing allows them to fit under stock fenders.

15. Wise’s sedan delivery will be shod with very aggressive 275/35R18s on Forgeline wheels. The deep backspacing allows them to fit under stock fenders.

16. Here’s a little teaser, Chevs of the 40’s rear subframe to mount a Corvette transaxle.

16. Here’s a little teaser, Chevs of the 40’s rear subframe to mount a Corvette transaxle.

17. The Corvette transaxle not only helps with front to rear weight balance, the IRS improves ride and handling.

17. The Corvette transaxle not only helps with front to rear weight balance, the IRS improves ride and handling.