Editor's note: Because we had so many articles to run in the September issue, including the 2008 Buyer's Guide, we were unable to run this story on former Editor Eric Geisert's California Hauler. So here it is!

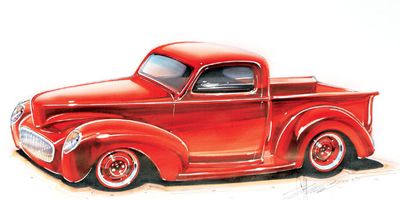

If you've been following the California Hauler build-up (the 'glass '41 Willys body from Auto Classics mounted to a stock Chevy S-10 chassis), then you know we visited Dagel's Street Rods in Orange, California, to use Gary Dagel's expertise in fabricating and locating the custom engine and transmission mounts.

Once that work was done, the next big step in the build was to begin adding the front and rear fenders. But in order to attach the rear fenders in the correct location, we had to address two items: wheel choice and ride height. Having the same wheels as you intend to actually run on the finished project is necessary because you will need to center the rear fenders directly over the wheel (many home kit builders don't, which is why their cars look like the worst kind of kit cars).

A change in ride height can be accomplished in a handful of ways, some better than others. Heating coil springs with a torch or adding bags of cement are methods we've actually seen people do to get their ride down on the ground, but neither is recommended. The high-end way nowadays is an adjustable air shock system, but some folks don't want to go to that extent.

Before Dagel's gets started on removing the leaf springs, we measured from the floor to the forward spring perch to see what the stock height is at this location, which is about 14 inches at the bottom of the hanger.

Before Dagel's gets started on removing the leaf springs, we measured from the floor to the forward spring perch to see what the stock height is at this location, which is about 14 inches at the bottom of the hanger.

One good method for the rear, especially if you want to retain the stock appearance of the truck's leaf-spring suspension system, is to have new springs made with the lowered dimensions already built in. And that's where Eaton Detroit Spring comes in.

Eaton Detroit Spring has been in business since 1937, with generations of the Eaton family making all types of springs for all types of vehicles. They specialize in factory-spec leaf springs, and their catalogue of over 160,000 spring applications has got to be the largest outside the Big Three (and that means they probably have the factory specs on your spring already in their filing cabinets).

But Eaton can also create custom springs (translated: for your lowered applications) based on the info they have in their blueprints. All they do is change the degree of the arch when they heat and forge the springs, and voil, a lowered spring assembly can be made. Plus, it's as easy as telling them what you have and how much you want it lowered, and Eaton does the rest.

Once the rear leaf springs go on, then we'll address the front coil springs. From there, we'll bolt up the new wheels and tires and look at attaching the rear fenders and the four-piece nose assembly (won't that be fun!). Hey, pretty soon we're gonna have something to look at!