The Direct Drive attachment design has several advantages over previous designs, without increasing the cost of the system.

The Direct Drive attachment design has several advantages over previous designs, without increasing the cost of the system.

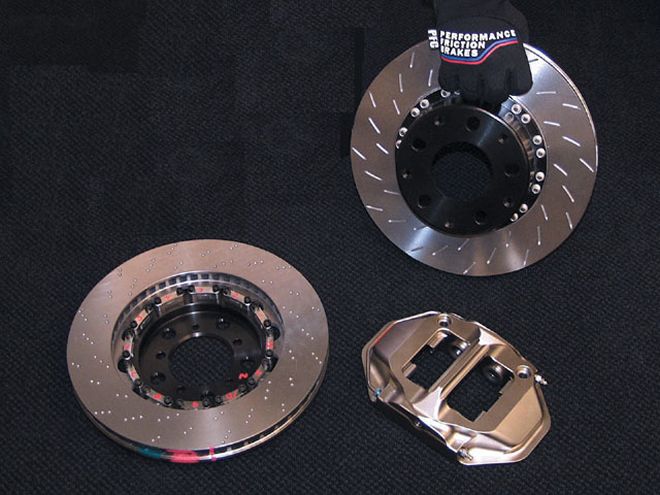

The top race parts companies work continually to improve their products for endurance and performance. That commit-ment is no more evident than at Performance Friction, a company that manufactures brake com-ponents for high performance race cars. This company has recently finished the design and testing of a new and improved attachment system for mating the brake rotor to the rotor hat. Past designs include the straight-through bolting design, and the T- bobbin hat design. The new patent-pending system is called the Direct Drive attachment system and it has improved the way the rotor operates by taking the moment out of the attachment, thus eliminating the disc twisting motion and drag, especially at high temperatures.

When we use the brakes on a circle track race car, the rotor temperatures can be extremely high momentarily and then fluctuate between entry and the rest of the lap. It is this fluctuation in temperature that causes some of the problems with the rotor and the rotor hat. If the attachment is not designed correctly, the rotor will develop a slight twist or warping as it heats up and cools. The Direct Drive system helps effectively compensate for the changes caused by constant heating and cooling.

The flanges designed into the rotor are held in place by clamps that are attached to the rotor hat by two bolts. In this way, the float is in the U-clamp instead of the hat.The new design allows it to adapt to the heat cycles, produces a longer hat life, and reduces twisting causing less brake drag. Drag reduction is a hot topic in racing circles today and anything that can help reduce that total parasitic drag in your race car is worth having.

The Direct Drive system is available for use in the top NASCAR divisions with a wider range of applications available in the near future. Extensive testing of this innovative system has shown better heat dispersion across the rotor friction surface, as well as less brake drag when the pads are in a resting position. More stopping power and less rotational drag add up to a marked increased in performance by just bolting on these rotors.