The DTS Dana 60 is constructed using only new components, at the center of which is an all new Dana 60 centersection. This rearend is a custom assembly and can be ordered in any width with any currently available ring and pinion ratio starting at 3.54 and up to 7.17:1.

The DTS Dana 60 is constructed using only new components, at the center of which is an all new Dana 60 centersection. This rearend is a custom assembly and can be ordered in any width with any currently available ring and pinion ratio starting at 3.54 and up to 7.17:1.

Project Roadrunner

At the 1999 Performance Racing Industry show held in Indianapolis, Indiana, we were on a mission. Having just recently observed the dyno results of the Indy Cylinder Head-built 542ci Wedge, we immediately recognized the need for a rearend assembly that would offer the strength needed to shelve our concerns for street reliability as well as occasional wheel-lifting launches.

Initially, we believed that a well-built 8 3/4 would easily meet our needs, but that was not the opinion of Jay Prosch-Jensen of Drive Train Specialists' Custom Services division. Jay said, "With the limited availability of seasoned 8 3/4 housings, we really would rather see you with a DTS Dana 60."

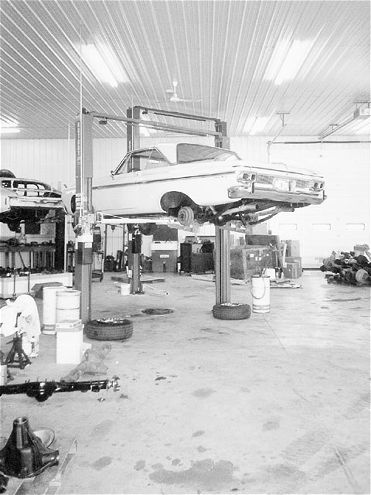

DTS, in addition to building custom rearend assemblies in both their Wayland and Warren, Michigan, locations, offers full-service installation as illustrated here.

DTS, in addition to building custom rearend assemblies in both their Wayland and Warren, Michigan, locations, offers full-service installation as illustrated here.

With the 542ci big-block already planned for back-up by a Herb McCandless-built A833 four-speed ("4-Speed Clinic," page 36, Mopar Muscle, June 2000), the thought of yet another assembly of Hemi legend made sense for the Holley Project Roadrunner. But this would not be a rebuilt Dana 60. "DTS Dana 60s are manufactured from 100 percent new components," said Prosch-Jensen. "Starting with new Dana 60 castings, a print is drawn to determine the length and pinion offset of the housing. Then a pair of 3-inch I.D. axle tubes are cut and turned in the lathe for a press fit. The rearend is installed in a jig to assure proper alignment during the process of welding the axle tubes to the center section."

Additionally, Jay and the crew at DTS Custom Services are quite familiar with the Mopars. Full service includes welding of suspension mounts in the proper location for specific applications.

Because of the multi-use characteristics of the car, we wanted the driveability of Sure Grip with the drag race reliability of a locker. With that in mind, Jay recommended the use of an ARB air operated locking differential. The Australian-built Air Locker-with a flip of a switch-converts from an open rearend to a spool. With the accompanying air compressor, you simply air up when you want to lock the differential.