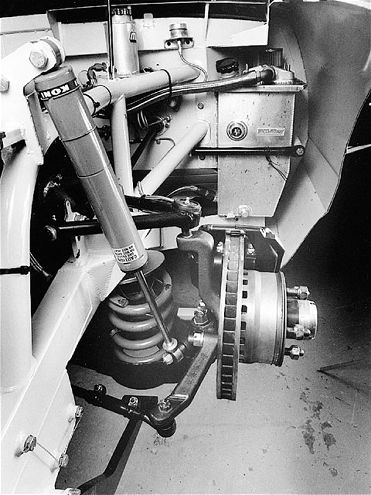

While coil springs seem simple, you may be surprised by how much you need to know to use them to go fast. Beyond the obvious buying springs with the spring rate you need for your application it is important to keep track of your springs so they don't lose their load capacity, because this will change the setup of the car.

Making Them

To understand springs best, it's important to know how they're produced. Springs are made of either chrome-silicon or chrome-vanadium wire that is ordered or ground to exact sizes. These high-strength materials allow spring manufacturers to make the springs from small-diameter wire, which saves weight and allows for more spring travel before coil-bind. The diameter of the wire is critical to the rate the spring has when it is complete, so the diameter tolerances are within thousandths of an inch.

There are many ways to make a coil spring, but for racing most are wound around a mandrel, either hot- or cold-rolled, followed by grinding, heat-treating, shot-peening, and painting. Before it is painted, the spring is compressed once to coil-bind so the spring won't settle in the future.

Considering they hold up the four corners of your car, your race car springs better be ready for action when you hit the track. Learn how to determine if they are "dead" or not.

Considering they hold up the four corners of your car, your race car springs better be ready for action when you hit the track. Learn how to determine if they are "dead" or not.

Using Them

There is a lot of talk about springs losing their rate from usage. This is a falsehood. Springs don't lose their rate. They can lose their free height, which results in a loss of load capacity. This is what racers describe as a spring that has "gone dead." To better understand this, here's an example from Richard Jonek at Eibach Springs in Irvine, California: "If a racer has a 200-in-lb coil spring that is 9 inches in length and has 5 inches of travel, that spring has a load capacity of 1,000 pounds. If the spring fatigues, ending up with a free height of 8.75 inches, it still has a 200-in-lb rate, but the travel has dropped to 4.75 inches. This changes the load capacity to 950 pounds."

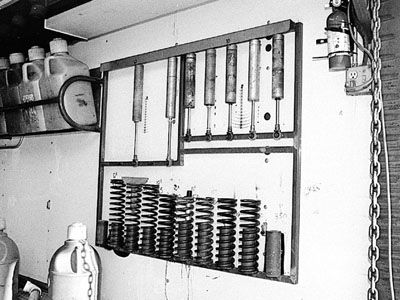

The usual reason for loss of free height is the choice of materials or the manufacturing process. The best way to avoid the problem is to buy quality springs, measure them the moment they come out of the box, and mark the free height on the spring with a date or in a log book. Check the springs periodically to make sure they haven't lost their free height, and if they have, replace them.

Determining Spring Rate

To determine the rate of a spring use this formula:

Rate = G (d)4 / 8 (Dm)3(n)

G = Modulus of Rigidity (psi)

Chrome Silicone = 11.7 x 106

Chrome Vanadium = 11.4 x 106

D = Wire Diameter

Dm = Mean Diameter (this is the inside diameter plus the coil diameter)

N = Total number of active coils plus

1.75-2.00 dead coils for two closed and ground ends

or 1.35- 1.50 dead coils for one open end and one closed and ground end.