It’s only natural that the retro styling of the Gen 5 Camaro inspires modifications and personalization from an earlier era. That’s why about 85 percent of the cars are rolling these days with SS-style hood stripes and/or hockey stick side graphics. And when it comes to vintage muscle, there’s hardly a more Chevy-centric engine than the 454 big-block. It was the motivation behind the Hemi-killing LS6-powered ’70 Chevelle SS, not to mention countless Chevy trucks through the ’70s, ’80s, ’90s and beyond. The funny thing is the Camaro never was offered with a 454. The special-order COPO cars from 1969 had 427-inch engines, while the big-blocks available in the second-gen cars were versions of the 396 (although they actually displaced 402 cubic inches). A few dealer-based special editions, most notably from Baldwin-Motion in New York and Berger Chevrolet in Michigan, built their own 454 second-gen cars, but that flavor of Rat never came from the factory.

Although the factory never offered such a beast, the elements are available from GM Performance Parts (GMPP) to build an LS-based 454 that will install in a new Camaro with the look and fit of a production-engineered powertrain. In fact, GMPP engineers have experimented with this combination for a while now and have come up with some very interesting results, all rooted in the LSX cylinder block. In its catalog, GMPP offers an LSX454 crate engine (PN 19244611) that is delivered minus the oil pan and intake system but includes LSX-LS7 six-bolt cylinder heads. It also offers an LSX454 Completion Kit (PN 19244481) that includes an LS7 intake manifold that’s pre-assembled with the fuel rails, injectors, and 90mm throttle body. Throw on the oil pan and front-end accessories from your SS’s LS3 and you’re ready to rock with an engine GMPP rates at 580 horsepower and 590 lb-ft of torque.

Besides the displacement—delivered by 4.185-inch bores and a 4.125-inch stroke—those 580 horses are motivated by a relatively large hydraulic roller camshaft with 0.648-inch lift (intake and exhaust); 236/246-degrees duration; and a tight, 110-degree lobe separation angle. That gives the crate engine an excellent balance of low-speed and high-rpm performance with very good overall driveability qualities—and unquestionably stout power ratings for a naturally aspirated engine. At least, it all looked good in the catalog and seemed like a great idea for a Gen 5 retrofit. And as luck would have it, a friend of ours was looking for something to build with a bare LSX block that had gone unused from a previous project that didn’t exactly get off the ground. He was thinking of building a 427-inch engine, but because the block hadn’t been finish-machined we talked him into following the GMPP recipe and stretching the bores to build a 454. “Hey,” we said. “We’ll build the engine more or less to their specs and dyno it to see if it comes close to the crate engine’s advertised power ratings. We’ll be doing our journalistic duty to keep them honest.”

That sort of integrity didn’t mean much to our friend, but after we suggested we’d pick up the next round at the bar we were sitting at, he was all for the idea. Now that was integrity. Another factor making the build more feasible was the line we had on a set of hardly-used LS7 cylinder heads that could be had for a “buddy” price. The LSX454 crate engine uses GMPP’s LSX-LS7 heads, which are essentially six-bolt versions of the production-engine LS7 heads, so airflow would be the same as the crate engine. And with no power-adder planned, we weren’t concerned at all about the difference in clamping strength between the six-bolt LSX heads and four-bolt production heads.

As it would turn out, the cylinder heads were the only used parts we’d use for our 21st-century 454. We studied the GM Performance Parts catalog, grabbed the part numbers for the necessary components, and started collecting the parts. A number of them we snagged by spending time on the GMPP website (gmperformanceparts.com), which has a commerce section where you can compare the prices of different dealers before ordering. To be honest, the site isn’t comprehensive and not everything we needed was there, but we were able track down the rest by taking the part numbers straight to our local Chevy dealer’s parts department. And in the case of some of the other parts, we went to the aftermarket. You’ll get the stats on them by following the accompanying photos.

Because the plan is to ultimately shove this project engine into a new Camaro, we only needed to purchase GMPP’s LS7 intake manifold assembly (PN 12610435) instead of the entire LSX454 Completion Kit, as we initially planned. That’s because the more extensive completion kit comes with an engine control module, wiring harness, and throttle pedal in addition to the manifold assembly—a setup aimed at retrofitting the engine in an earlier car. Our engine builder/tuner assured us he could get the project running with a Camaro’s stock controller, making the rest of the completion kit’s contents superfluous. The basic (and less expensive) LS7 manifold assembly still came pre-assembled with the fuel injectors, fuel rails, and throttle body. Nice.

We were concerned that the stock 39-pound/hour injectors in the intake manifold wouldn’t be sufficient for an engine that was nearly 30 cubic inches larger than the LS7 and was projected to make nearly 100 more horsepower. But that’s what the LSX454 crate engine uses, so we would put our trust in the GMPP engineers and go with the as-delivered injectors. The larger concern, however, would be feeding those injectors sufficiently once the engine was in the car, but that problem solved itself by the time we were finishing up our dyno tests (see sidebar, “The ZL1 Pump”).

Of course, the camshaft is at the core of an engine’s capability to move air and for that, we copied the engineers’ homework and ordered the same hydraulic roller camshaft used in the crate engine. In fact, with emulation of the crate engine’s performance this project’s goal, we had little choice but to use it. Fortunately, it is available separately under part number 19166972. Its big 0.648/0.648-inch lift numbers come with a set of 1.8-ratio rockers. They need stout valvesprings, too, which we sourced from COMP Cams. None of the springs we saw in the GMPP catalog could handle that lift. The stress on 1.8 rocker arms used with such a robust valvetrain combination was a concern, too, but so far, so good.

Because the plan was to test our 454 on an engine dyno before swapping it into a Camaro, we simply bolted on an oil pan that was lying around the shop. We’ll transfer the oil pan, oil pickup, front-end accessories, and other necessary components from the project car’s LS3 engine. So, with that, the engine was finished off and hauled across town to the dyno room at Jim Kid Motorsports, where the engine was put through its paces. And you know what? We kept those GMPP engineers honest. The engine made the power they advertise for the crate engine and did it repeatedly. Sure, there was some fluctuation, but we got a nice peak of 584 horsepower at a lofty 6,200 rpm and 594 lb-ft of torque at 4,800 rpm—all with optimal fuel from the injectors. They held up just fine.

Generally speaking, the engine built horsepower quickly and sustained it very well above 5,000 rpm, where we expected it, but we were really impressed with the torque. It was making 400 lb-ft just past 2,000 rpm and built steadily to its 594 lb-ft peak. It fell off quickly after 4,800 rpm, but that’s where the horsepower came on strong. That should translate very well in a heavy Gen 5 Camaro, where the robust low-rpm torque will get the car moving and the high-rpm horsepower will make it fly down the track. We were more than pleased with the results, which delivered nearly 160 more horsepower than a Camaro SS’s LS3. Sure, the iron LSX block adds about 100 pounds to the overall weight when compared with the LS3, but adding a bolt-on supercharger and the related intercooler system will cost nearly as much in added mass. No heat soak at the track to worry about, either. And besides that, everyone is rocking the blower these days, but we’ll be the first with 454 fender badges. It’s 1970 all over again!

01. Here’s where we started: The LSX Bowtie Block (PN 19213964) with the production-spec 9.250-inch deck height (delivered unfinished at 9.260 inches). At less than $2,000 a copy, it’s an economical foundation for a high-performance LS engine.

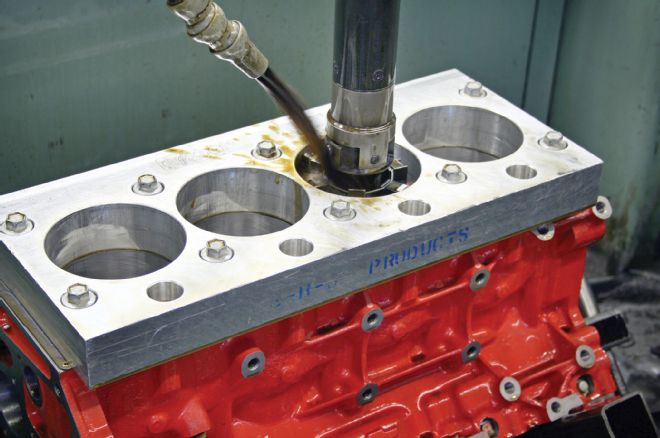

02 .The LSX block is delivered with 3.880-inch semi-finished bores, which must be cut out to 4.185 inches to support the 454-inch displacement. The thick deck plate simulates the clamping pressure of the cylinder head on the deck, ensuring optimal bore dimensions when the engine is assembled.

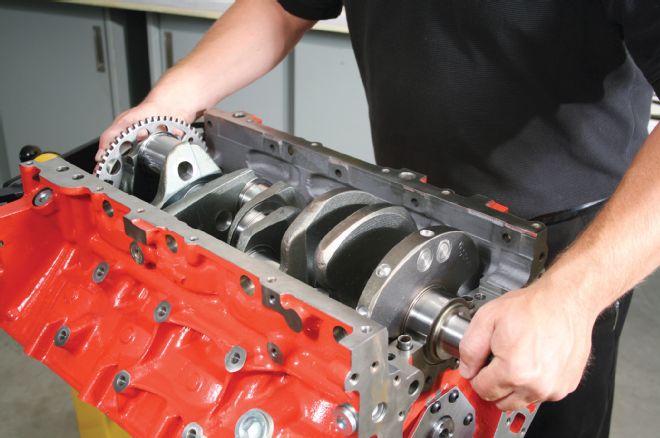

03. Sticking with the factory recipe, we ordered the same, 4.125-inch-stroke, 4340-forged steel crankshaft used in the LSX454 crate engine (PN 19244018). It included the necessary 58X reluctor wheel but came with a non-standard, eight-bolt flywheel-mounting flange.

04. The supercharged LSA is the only production LS engine that uses an eight-bolt flange for the flywheel, while other LS engines use a six-bolt flange (the LS9 uses a nine-bolt pattern). Aftermarket eight-bolt flywheels are available from several manufacturers that will work in concert with a higher-capacity clutch (required with the 454) to mate up to a Gen 5 Camaro. However, the LSA flexplate will work perfectly for factory 6L80Es. Call Thomson Automotive for an adapter if you plan on running a 4L80E, TH400 or other conventional GM trans.

05. We also went with GMPP for the LSX connecting rods (PN 19166964), which are stout, 4340 forged-steel parts with premium, 7/16-inch, 12-point SAE 8740 rod bolts. They’re 6.000-inches long for our engine, but are also offered in 6.098- and 6.125-inch lengths.

06. We couldn’t get a set of matching LSX forged pistons to go with the rods, but we located a strong set of Diamond forged pistons that matched our needs for the 4.185-inch bores. They needed to be machined to match the 0.866-inch wristpin bores of the LSX rods, however.

07. The rod/piston assemblies were cinched down to a preliminary specification then final-torqued using the stretch method, which delivers a more accurate and optimal torque yield. With the stock LS7 heads we’ll be using, the compression ratio with this rotating assembly works out to about 11.0:1.

08. The camshaft is the same big-lift hydraulic roller specified for the LSX454 crate engine, which delivers 0.648-inch lift (intake and exhaust) with 1.8-ratio rockers, 236/246-degrees duration, and a 110-degree lobe separation angle.

09. We used a GM oil pump for the engine (PN 17801830). It works great with LS engines that don’t employ the cylinder-deactivating Active Fuel Management feature or (obviously) use a dry-sump oiling system. The LSA oil pump is a higher-volume pump but more than we needed for our naturally aspirated engine. Note, too, the three-bolt timing gear that matches the pattern on the camshaft. Later-production LS engines (such as the LS3) have a single-bolt camshaft fastener, which won’t work with the more common three-bolt timing gears.

10. We buttoned up the front of the engine with a front timing cover from GMPP (PN 12600325) that came with the camshaft position sensor. We used it with a “placeholder” harmonic balancer, because we’ll use the balancer from the engine in our project car when the time comes to swap the engine, although with the work it takes to secure it—about 250 ft-lb—we’re not looking forward to playing another round of “tighten the balancer.”

11. One of the caveats of building a big-stroke LS engine is ensuring adequate clearance for the rotating assembly. So, before bolting down the windage tray, we set it in place and carefully rotated the crankshaft to see if there were any interference issues—and there were. The bottoms of the rods touched the tray.

12. Fortunately, the interference between the rods and windage tray was only a matter of a couple of millimeters. By using a few washers on the main cap bearing studs that the tray bolts to, we were able to raise the tray enough to provide adequate clearance. Problem solved.

13. LS builder’s tip of the day: Because the oil pump is crankshaft-driven, there’s no way to do a conventional priming of the oil system—such as using a drill in the distributor hole of an old small-block. So, filling the oil pickup with oil during assembly will help the system pressurize quicker when the engine is started for the first time.

14. We’ll swap the LS3 oil pan from our Camaro project car when the time comes, but for now we used a fourth-gen F-body pan to hold the oil in place for our dyno tests. And if you haven’t built an LS engine before, you’ll need to invest in a torque wrench that measures in angles, not just lb-ft or Newton meters.

15. Going with the GMPP catalog again, we ordered a set of hydraulic roller lifters (PN 12499225) that work on just about every LS engine. They were soaked in motor oil for a few moments prior to installation, allowing the oil to seep in and help prime the lifters for the engine’s first start.

16. A set of LS7 heads that had been used only briefly came our way, and after a quick clean-up we wasted no time in setting them in place on the LSX block. If you need a reminder, the LS7 heads feature 2.200-inch titanium intake valves and 1.610-inch sodium-filled exhaust valves. The valves in the heads we bought had been swapped for conventional, high-performance stainless parts for durability’s sake, which was fine with us, given the engine’s capability of about 100 horses more than a stock LS7.

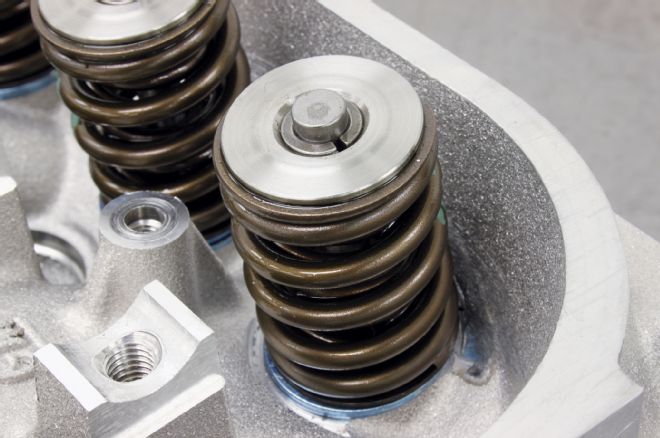

17. We spent a few bucks on the valvesprings and titanium retainers, going with a set of COMP Cams’ dual springs (PN 26921-16), which will stand up to the cam’s big lift capability. Stock beehive-style, single-coil springs and even COMP’s high-performance beehive springs can’t handle the lift of the LSX454 camshaft. The open load on the springs is 400 pounds, while the seat load is 135 pounds. All told, the springs and retainers set us back about $660, but they make for a necessarily strong valvetrain.

18. We matched the COMP springs and retainers with GMPP’s 1.8-ratio rocker arms. We ordered eight of the offset intake rockers (PN 12579615) and eight of the straight exhaust rockers (PN 12579617). Roller-tip rockers would have been nice, but these will do, as we try to match the performance of the LSX454 crate engine.

19. One of most value-driven parts of the project was the LS7 intake manifold assembly (PN 126104354), which comes with the 90mm electronically controlled throttle body, fuel injectors, and fuel rails installed for around $850—even less from some online sources. If you’ve priced aftermarket LS intakes, along with buying the other parts separately, you’ll understand that this is a screaming deal. In fact, you’ll spend less on this complete assembly than the cost of some bare aftermarket manifolds alone.

20. Because the LS7 head design has a taller perimeter rail, we had to go with the stock LS7 valve covers. Fortunately, they were thrown in with the heads we bought, as well as the ignition coils. These are parts we won’t swap with the LS3 components from our project car.

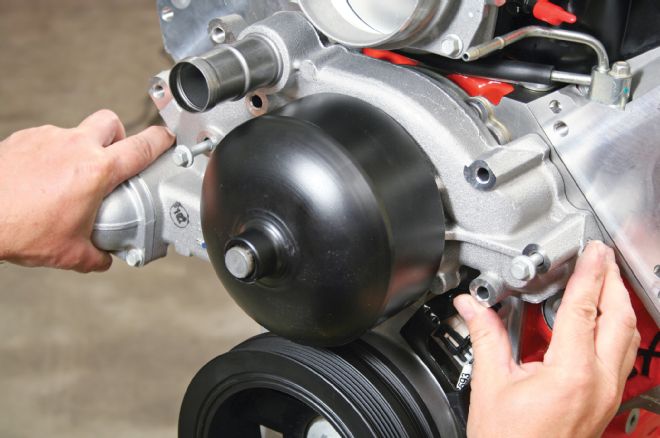

21. There are several water pumps from GM that fit LS engines, each designed for different vehicle applications. Lucky for us, the LS3 and LS7 water pumps are essentially the same, so we grabbed part number 89018052 from the GMPP catalog and bolted it on the engine.

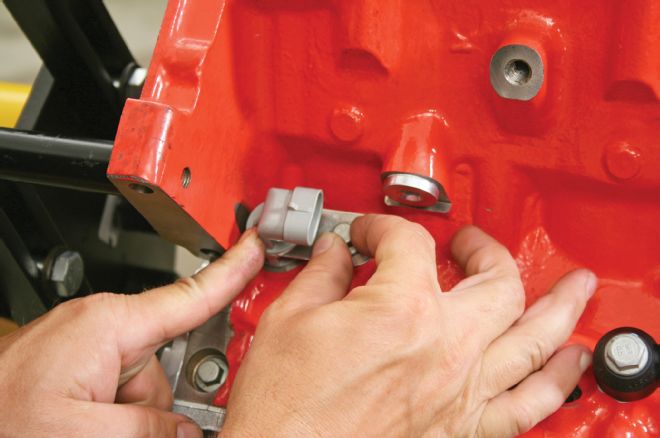

22. We’re down to the final details on the assembly, installing myriad sensors around the engine, including the crankshaft position sensor, shown here.

23. Here’s the assembled 454 engine. We like the classic Chevy orange color of the engine block, even if it reminds us the iron block is heavier than an aluminum block. Then again, with almost 600 naturally aspirated horsepower, those extra pounds won’t be felt.

24. At Jim Kid Motorsports, our project engine made 584 horsepower and 594 lb-ft of torque, but that was made through LS7 exhaust manifolds. They won’t fit the Gen 5 Camaro chassis, so we’ll have to go with aftermarket headers—a modification that will definitely add even more power.

25. Time and money are all that are keeping us from lowering the stock LS3 out of our Camaro SS project car and shoving in the new 454 (but we’re working on it).

The ZL1 Pump

Just as we finished our LSX 454 engine project, we found out that GM Performance Parts was releasing the fuel pump from the 2012 Camaro ZL1 (PN 19258436). It’s an in-tank pump that delivers 250 lph at 65 psi. That’s good enough, they say, to support at least 600 horsepower. And with the ZL1 being supercharged, it’s definitely a great choice for power-adder combinations.

The ZL1 fuel pump module incorporates a twin-pump design and is pulse-width modulated, directed by a fuel pump controller for more precise fuel delivery that eliminates the need for a conventional pressure regulator. Components of the kit include the fuel pump/sender assembly, a fuel pump seal, and instruction sheet. We can already think of a million uses for this part, starting with our LSX 454 project engine.

Engine Dyno-Testing Results (SAE Correction) RPM LB-FT HP 2,800 471 280 2,900 480 296 3,000 483 311 3,100 488 323 3,200 496 334 3,300 500 359 3,400 511 366 3,500 520 370 3,600 526 378 3,700 531 385 3,800 538 399 3,900 544 408 4,000 550 419 4,100 558 432 4,200 562 450 4,300 570 462 4,400 578 475 4,500 584 488 4,600 589 499 4,700 593 503 4,800 594 522 4,900 580 486 5,000 565 508 5,100 543 527 5,200 532 531 5,300 530 540 5,400 527 544 5,500 520 550 5,600 516 551 5,700 515 555 5,800 518 560 5,900 518 565 6,000 516 577 6,100 509 580 6,200 505 584 6,300 500 580 6,400 498 572