There's an old automotive adage that says when it comes to performance "there's no replacement for displacement." That holds particularly true when the vehicle in question tips the scales at near 3,900 pounds empty like our 2015 ARP/Street Rodder Road Tour 1961 Ford Sunliner. Add to that a trunk full of designer shorts, T-shirts, and the vast array of hair care products required by our Road Tour leader, Jerry Dixey, and it will take some grunt to haul our ragtop over hill and dale.

While we could have stayed with any one of Ford's original FE designs (352- and 390ci versions were available in 1961), we opted to go for something more contemporary from Ford Racing and Performance Parts' (FRPP) crate engine offerings. After all, when you think about it, who knows more about Ford engines than Ford Racing engineers? Each FRPP engine is hand built using the best factory and aftermarket parts, and non-racing versions are covered by a 2/24 (2-year/24,000-mile) warranty. Those with Ford blue blood can certainly find something to their liking in the FRPP catalog as pushrod, Modular, and Coyote engines are available with horsepower numbers ranging from 340 to 600 plus.

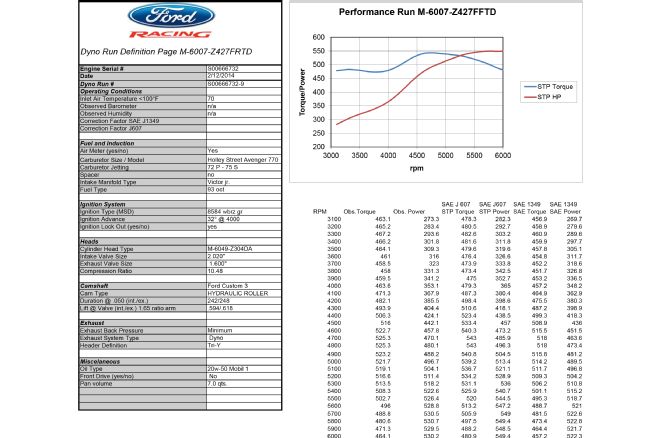

For our needs we chose PN M-6007-Z427FRT—a 427ci small-block that produces maximums of 535 hp at 5,600 rpm and 545 lb-ft of torque at 4,500 rpm. These engines are based on blocks that Ford Racing Engineers designed as replacements for the legendary BOSS 302 and 351 blocks. According to FRPP these new blocks are cast from diesel grade iron and designed with added material in key areas, which makes them far superior to any Ford OE block ever produced. In addition, by maintaining many of the dimensions and features from the original 289-351 blocks, these new BOSS blocks can be used with just about any vehicle that used a Windsor-style engine.

FRPP's new BOSS 302 and 351 blocks are the basis for a variety of crate engines and short-block packages. The smaller blocks are the basis of the original screamer, the 302 (4.00-inch bore x 3.00-inch stroke). Taking a page from the hot rodder's playbook, FRPP bored and stroked the 302 to come up with the 347 (4.030-inch bore x 3.400-inch stroke) and the 363 (4.125-inch bore x 3.400-inch stroke). For those wanting a bigger small-block the BOSS 351 casting is used for the 374 (4.125-inch bore x 3.500-inch stroke) and the 427 (4.125-inch bore x 4.00-inch stroke).

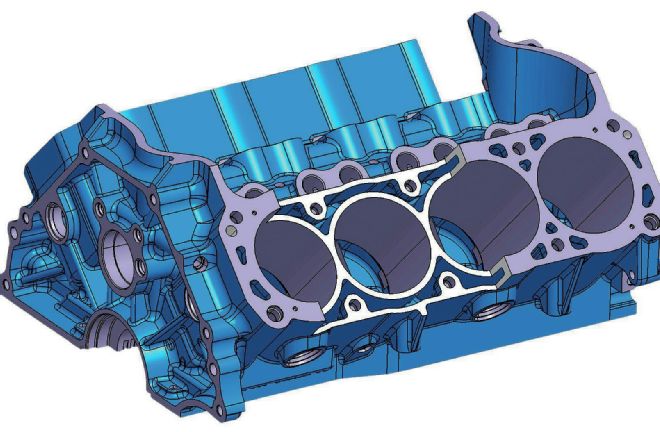

New castings take a monumental commitment of resources. FRPP engineers created cylinder blocks and heads using the latest processes in computer modeling, high-speed machining, and casting simulation. These processes were developed while creating components for the NASCAR racing series and have proven to deliver high-quality components for the track and the street. According to our friends at FRPP, "Every new major component at Ford Racing starts out as a detailed solid CAD (computer aided design) model of the casting. The next step is to add the final machining to the model."

Once the virtual machining is added to the model, it's ready to be used to determine the mass of the component and to perform CAE (computer-aided engineering) analysis. CAE analysis is performed to ensure the component isn't over-designed, which would create unnecessary weight. The analysis is also used to ensure that the component has the required strength and durability for high-performance applications. After the CAE analysis is complete and the results are acceptable, the next step is to ensure the component is feasible for casting. This is done with casting simulation software. The art of making a high-quality casting involves proper metal filtering, keeping metal velocities low, and directional solidification. All of this can be done in the virtual casting world with simulation software.

Creating new molds for a new cast engine component is done on CNC (computer numerically controlled) machines. The same CAD model that was used for the previous simulations is used for the machining, creating an exact copy of the virtual part. Finally liquefied metal is poured into sand cores made from the molds and after cooling, the sand cores are broken off, leaving the high-quality FRPP component."

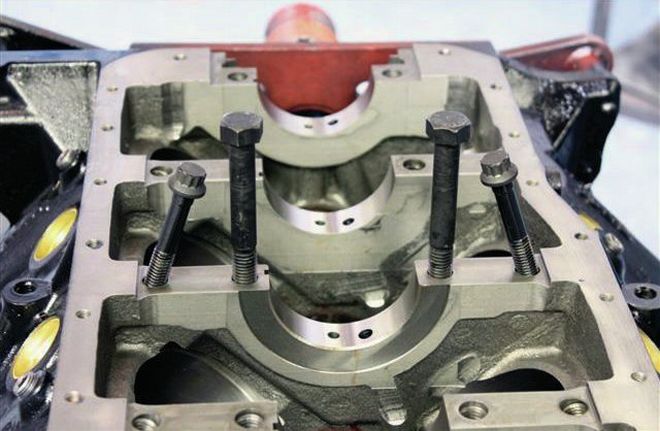

The new BOSS block has a host of refinements—there are splayed, four-bolt caps on mains 2, 3, and 4 (1 and 5 have two bolts); main bearing diameters have been increased to 2.749 inches (the same as the 351C) and the blocks are machined to accept factory roller lifter guides and a lifter guide retainer. The oiling system has been improved with NASCAR-inspired front oil feeds on both lifter galleys. To increase strength additional material has been added to the main bearing bulkheads and to aid cooling the Siamese bores have drilled coolant crossovers.

Although our BOSS 427 makes plenty of horsepower and torque for anyone in their right mind, we've decided to explore the outer limits. The engine for the ARP/Street Rodder Road Tour car will be specially built with lower compression ratio 9.0:1 pistons to go along with the TorqStorm superchargers we will be adding (and yes, that means two of them). Stick around, we guarantee this will be interesting.

Boss Specifications at a Glance:

Displacement (CI): 427

Bore x stroke: 4.125-inch bore x 4.00-inch stroke

Block: Boss 351 9.5-inch deck

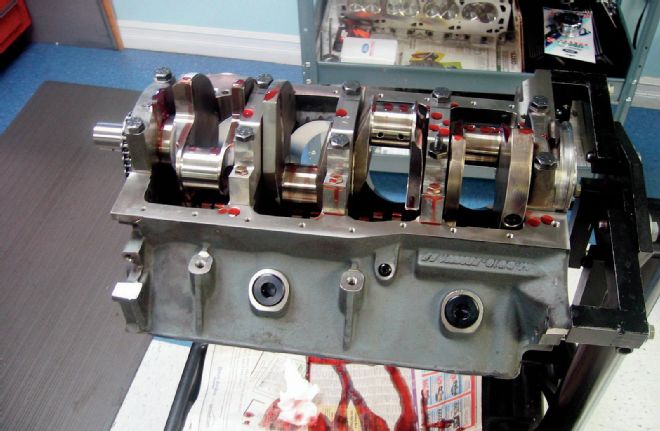

Crankshaft: SCAT

Connecting Rods: SCAT H-beam connecting rods

Pistons: Forged Mahle

Camshaft type: Hydraulic Roller

Camshaft lift: 0.594/0.618 inch

Camshaft Duration (at 0.050 inch): 242 degrees /248 degrees

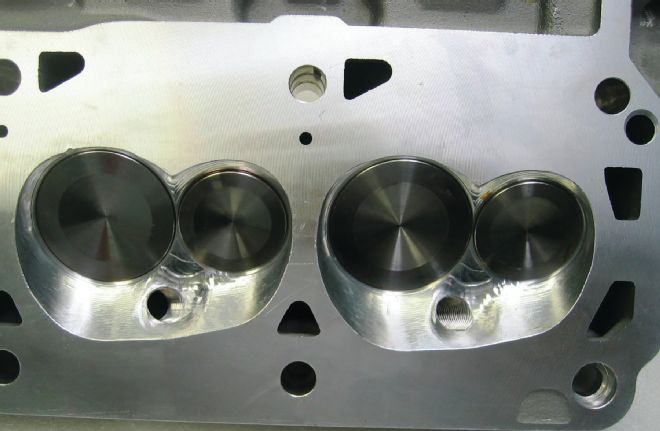

Cylinder Heads (PN M-6049-Z304DA): Ford Racing Aluminum "Z" cylinder heads

Valve size: 2.02 inches intake, 1.60 exhaust

Compression ratio: 10.5:1 (nominal)

Rocker arms: Roller Rockers

Rocker arm ratio: 1.65:1

Vibration Damper: Ford Racing SFI Approved

Valve Covers: Ford Racing cast aluminum black wrinkle finish 427 Cobra Script

Oil Pan: Steel deep rear sump pan with windage tray/scraper—7-quart capacity

The Ford Racing and Performance Parts team spent lots of hours looking through the dyno room window while developing the new BOSS block. We'd say the results were worth it.

Rather than plucking something from the assembly line, FRPP stepped up and designed an entirely new BOSS block.

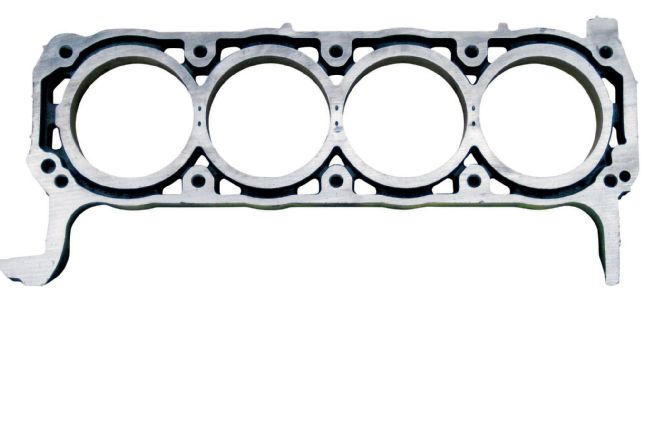

To fit the 4.125-inch cylinders into a relatively compact space and maintain the necessary cylinder wall strength the bores are Siamese.

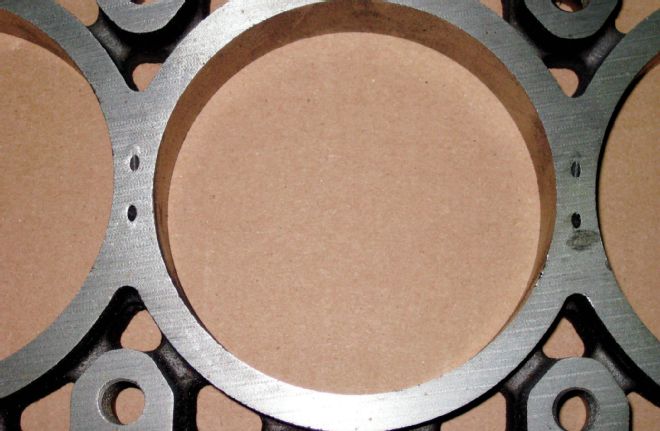

In this slice taken from a production block the coolant crossover passages in the deck can be seen.

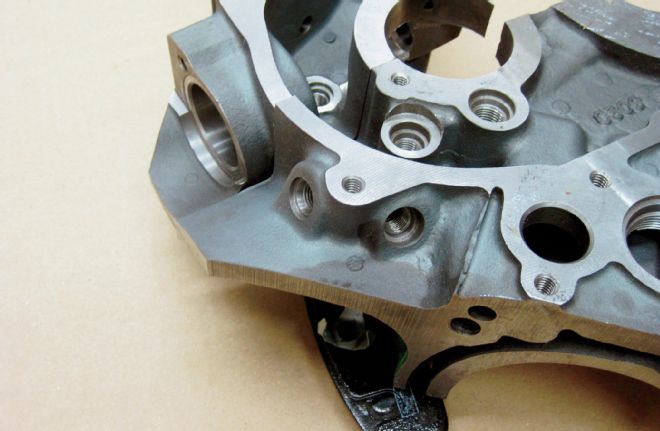

Up front the oil galleys in the block leading to the lifter bores have been redesigned to improve lubrication. Note the threaded galley plugholes.

The forged rods are from SCAT; the custom Mahle pistons feature full-floating pins.

To reduce friction the pistons have been treated with Grafal coated skirts. Normally the compression ratio is 10.5:1—ours will be slightly lower.

Bottom end strength is improved by the use of four-bolt caps on mains two, three, and four and thicker bulkheads in the block (photo by Jay Storer).

SCAT supplies the forged steel crankshaft. Note the motor mount bosses are typical small-block Ford and the soft plugs are the O-ringed, screw-in type.

For a solid bottom end steel main caps are used on the second, third, and fourth main bearings. The high output oil pump will be inside a 7-quart pan.

The new block is immediately identifiable by the Boss 351 cast into it. Timing chains and sprockets are the double-row design, and there are more screw-in soft plugs up front.

Like the production blocks shown here, the BOSS versions accept roller lifters and the sheetmetal spider that keeps them aligned (photo by Jay Storer).

The T6 aluminum cylinder heads are part number M6049-Z304DA. The come with 2.02-inch intake valves and 1.60-inch exhausts. Combustion chambers are 63 cc.

Included in the valvetrain are full roller rockers. These are from COMP Cams.

The New Boss crate motor comes with an SFI approved vibration damper and standard rotation water pump. These engines are internally balanced and require a neutral balance flywheel.

Check out the dyno data for a typical street build with a Victor Jr. intake and 770 Holley Street Avenger.