When 532 ci, 786 hp, and 9-second e.t.'s in a full-weight street car just won't cut it anymore, there's only one reasonable solution. Extra cubes? Too boring. More cam and rpm? Too incremental. A 600hp hit of nitrous? Too easy. At this level, any aspiration of doubling or tripling horsepower output requires transcending the barriers of natural aspiration in favor of forced induction. That's precisely why we decided to hang a pair of 88mm turbochargers off of our trusty big-block Ford. With the preliminary turbo fabrication complete, it's time to build the bulletproof short-block that will hold it all together, and Ford Racing's A460 block is the perfect tool to encase it in. The goal is to make 1,500 hp and run 7.90s in the quarter-mile on a low-boost, pump-gas tune with enough psi left in the tank to crank it up to over 2,000 hp on VP Fuel's Q16.

Back in the June '09 issue, we enlisted the School of Automotive Machinists (www.SAMRacing.com) to build a 532ci big-block Ford for our '93 Mustang project car. Based on a factory 460 block, the combination produced 786 hp thanks to a set of Kaase P51 cylinder heads, an Edelbrock Victor intake manifold, a Holley 1,150-cfm Dominator carb, and a big COMP solid-roller camshaft. After reaching our goal of consistently running high 9-second quarter-miles at over 140 mph, the car started feeling way too slow. In fact, it felt slow after about a half-dozen passes, and watching the occasional small-block car run neck-and-neck with us didn't do much for the ego. As luck would have it, we crossed paths with a local Outlaw 10.5 racer looking to unload his Garrett GT47 88mm turbos for the latest and greatest huffers on the market. We had to buy them, and even though it's been several years since we retired the Fox Mustang from PHR's project car stable, we've been working behind the scenes to throw some positive manifold pressure at it all along.

Understandably, cranking out thousands of horsepower may seem cuckoo, but our target horsepower goal is actually quite pedestrian in the world of twin-turbo big-blocks. Massive cubic inches and cylinder head airflow provide the capacity and unhindered airflow necessary to produce incredible horsepower at relatively low boost pressure. In the ranks of Outlaw 10.5 drag racing, twin-turbo big-blocks measuring 540 to 565 ci easily crack 2,900 hp at 30 psi of boost. In fact, in their past lives our used turbos powered both a third-gen Camaro and a Chevy II to 6.60s in the quarter-mile. For comparison sake, a dinky four-banger can barely hit 550 hp at a similar boost level. Quite frankly, we don't have enough rollcage or enough driver skill to max out the 88mm turbos, so our plan is to limit the boost to a more manageable 15-20 psi, which should be enough to hit our power.

Prepping For Boost

To simplify the turbo big-block build, we will carry over as many parts from our old 532 as possible. Displacement will stay in the 532 to 547ci range, and although we considered retaining the production block, after working out the math it just didn't make any sense. Unlike its small-block Windsor relative, the factory 429/460 block is one stout piece of hardware. Reigning Engine Masters champ Jon Kaase tells us that he's been running a production-block–based 521ci test mule for years that's still holding up after thousands of pulls at 900 hp. In boosted applications, factory 460 blocks have been known to survive at 1,500-plus horsepower when upgraded with four-bolt main caps and filled with Hard Blok. Nevertheless, these upgrades can cost over $1,000, and at the end of the day you're still stuck with a production block that's prone to flexing and eating up main bearings.

By spending money on hardware instead of labor costs, aftermarket blocks like Ford Racing's A460 offer far more value for the dollar with features that an upgraded production block simply can't match. Not only is the Ford Racing block cast from a more durable iron alloy, it also boasts nodular four-bolt main caps, a priority main oiling system, beefier main webbing and oil pan rails, and casting reinforcements. Of particular importance in a boosted application is the A460 block's solid deck surface and 18-bolt cylinder head configuration, which substantially increases cylinder seal under boost. Brute strength aside, the Ford Racing block's siamesed bores can accommodate up to a 4.600-inch bore diameter. Matched with a max stroke capacity of 4.500 inches, the A460 block can be built as large as 598 ci.

Over the next several months, we will outline the build of our turbo big-block Ford in multiple installments as the crew at the School of Automotive Machinists works their magic once again. Stay tuned as we tackle the short-block build, top end assembly, fuel system setup, turbo layout, and dyno testing. In the meantime, here's a side-by-side comparison of the Ford Racing A460 block with a production 460 block. The differences are staggering to say the least, and it sure makes us glad that we decided to do things right the first time!

By the Numbers Ford Racing A460 Block

PN: M-6010-A460 Price: $2,529 Material: cast iron Maximum bore: 4.600 inches Maximum stroke: 4.500 inches Maximum displacement: 598 ci Deck height: 10.322 inches Main bearing bore: 3.1922 to 3.1930 inches Cam bearing bore: 2.2495 to 2.2505 inches Lifter bore: .8752 to .8767 inch Main caps: splayed 4-bolt nodular iron on 2, 3, and 4 Oiling: priority main, wet sump Weight: 276 pounds

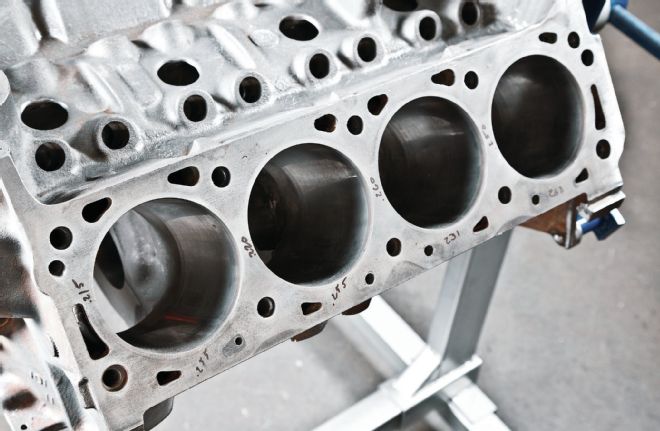

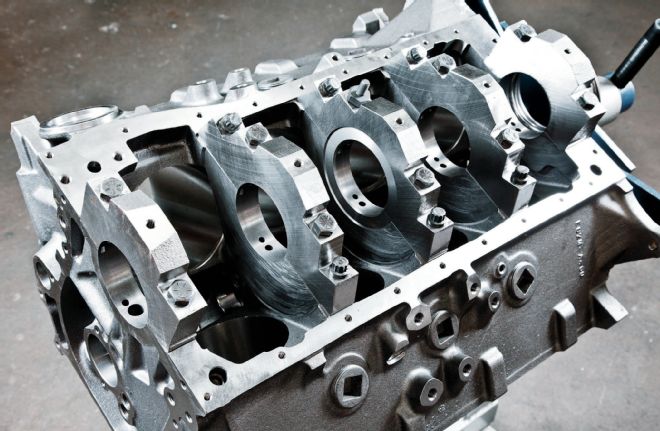

1. Ford Racing's A460 block provides just the beefcake we need to make over 2,000 hp. It comes rough bored to either 4.340 or 4.490 inches, and thanks to siamesed bores it can accommodate up to a 4.600-inch max bore. While some production blocks can handle up to a 4.500-inch bore (.140 over), most are limited to a 4.440-inch (.080 over) maximum bore diameter.

2. One of the most noticeable additions to the Ford Racing block (top) are its two additional head bolt provisions on the top and bottom of each cylinder, which aren't present on the production block (bottom). Although not entirely necessary in a naturally aspirated application, having 18 bolts anchoring each cylinder head instead of just 10 increases the clamping load and provides extra insurance against blown head gaskets in a forced-induction combo.

3. An unexpected yet very welcome feature of the Ford Racing block (top) is its solid deck design. The large water jacket openings in a production 460 block (bottom) can make the deck surface prone to distortion under high boost conditions. On the other hand, Ford Racing has press fit steel inserts into the water jacket openings to substantially increase deck surface rigidity. Even with aftermarket blocks, this isn't a common feature.

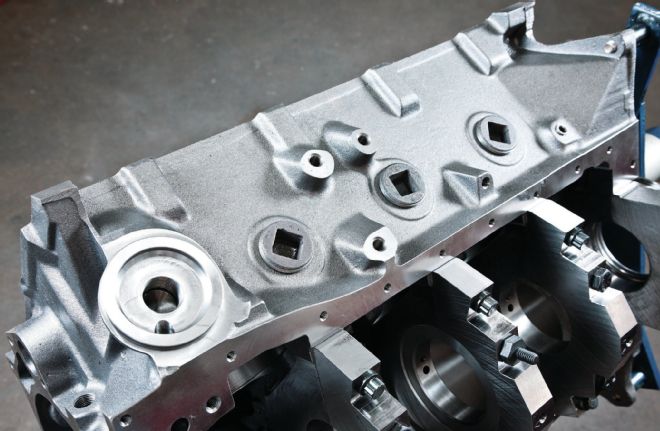

4. To the naked eye, the lifter valley area of the Ford Racing block looks very similar to a production block, but the casting material is much thicker. This ties each bank of cylinders more rigidly together.

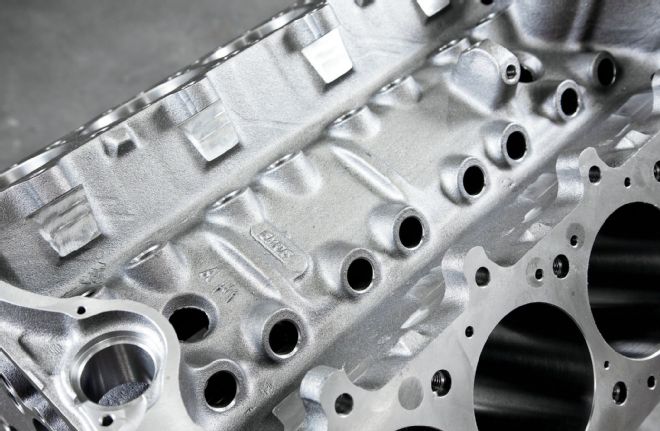

5. A series of divots and indentations run the length of the factory block (bottom). On the Ford Racing unit, all the divots have been filled in to increase strength. Additionally, strengthening ribs run front to back, and the motor mount bosses have been reinforced as well. The Ford Racing block also includes threaded core plugs, which make it much easier to drain coolant from the block for servicing.

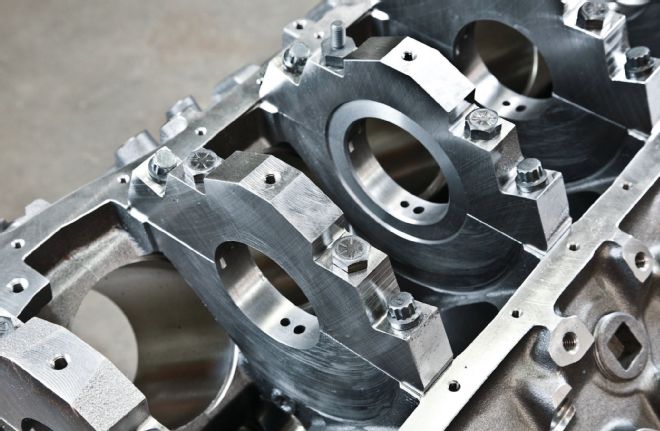

6. The outer bolts on the Ford Racing block's four-bolt main caps (top) anchor into beefy main webbing. Installing four-bolt caps on a production block (bottom) requires drilling and tapping into the narrow factory webbing.

7. Thin, concave sections of the oil pan rail on the production block (bottom) provide little support for the cylinder bores. This area is critical to overall durability, as it ties the cylinders, the main bearing bulkheads, and the bottom of the block together. On the Ford Racing block (top), the pan rails are much thicker and have been completely filled in.

8. The main bearing bulkheads on a production block (bottom) get very thin near the cylinder bores. This scalloped shape can potentially compromise crankshaft support under extreme loads. In contrast, the Ford Racing block (top) is built like a tank.

9. The Ford Racing A460 block incorporates one oil galley for the mains and rods, and one oil galley on each bank of cylinders, for a total of three. Routing oil to the mains first significantly reduces the potential for smoking a bearing. In contrast, a production 460 block has just one oil galley for each bank of lifters, for a total of two. Oil is first routed to the lifters then gravity fed to the mains.