Editor’s Note: We wanted to step out of our comfort zone just a little, and dive into a build that we wouldn’t normally highlight for you guys. We try to keep the majority of our edit focused on the street-performance arena, so when we got a call from Rich Nedbal inquiring if we would like to cover the build of a blown, Methanol-injected race Hemi, we were more than enthusiastic.

Originally, our block was used in a 900-horsepower N/A build. It features 41⁄2-inch cylinder bores and a non-raised camshaft journal. It’s also a “water block” which is a requirement for longevity of this build.

Originally, our block was used in a 900-horsepower N/A build. It features 41⁄2-inch cylinder bores and a non-raised camshaft journal. It’s also a “water block” which is a requirement for longevity of this build.

We’re sure you already appreciate the horsepower advantages that Chrysler has bequeathed to us. The founding father of this advantage is the second-generation 426 Hemi. Sure, the Hemi started it all back in the 1950s, and the new Hemi is a very impressive engine, but look at a Top Fuel or Top Alcohol Dragster and you’ll see a second-generation Hemi.

Several years ago, I built a normally aspirated version of this legendary engine, called the Pump Gas Hemi. With that engine in a race car, I won the 2010 NHRA ET finals in Division 7. The objectives at that time were to build a very reliable, low-maintenance Hemi in the 900-horsepower range. It performed as designed, with mid 7-second e.t.’s, and no breakage in over 300 passes. But to run in the relatively new Top Dragster class, the car needs to be running 6-second e.t.’s. The math said that we would need close to 1,500 horsepower. Was this possible without compromising reliability? 1,500 horsepower is very achievable, without going to the extremes that would be required by classes such as Pro Mod or Top Alcohol.

Nitrous is the fastest, easiest, and least expensive way to gain 200-400 horsepower, but the Top Dragster Class is basically a high-speed bracket class that requires consistency. It’s hard to maintain consistent e.t.’s as the nitrous bottle’s pressure drops. Also, at this power level, the bottle would only last for a few passes. It’s great for heads-up racing, but dubious for e.t racing. Our next idea was forced induction. Even though centrifugal superchargers such as a Pro Charger are very impressive technically, what looks more natural in a dragster than a Roots-style blower sitting on a Hemi? So we found a used Mooneyham 10-71 that fit the bill, and the math says we’ll only need about 10 pounds of boost to get the target horsepower.

What parts can we keep from the pump-gas engine?

The 4340 forged crankshaft has a 41⁄2-inch stroke with 2.200-inch rod journals. It’s more than capable of handling the power. The only change was to add a second keyway slot for the blower hub. The small journals, along with the smaller big end of the connecting rods, means no additional clearancing of the block is required for the larger stroke, and there are no rod-to-camshaft clearance issues.

The 4340 forged crankshaft has a 41⁄2-inch stroke with 2.200-inch rod journals. It’s more than capable of handling the power. The only change was to add a second keyway slot for the blower hub. The small journals, along with the smaller big end of the connecting rods, means no additional clearancing of the block is required for the larger stroke, and there are no rod-to-camshaft clearance issues.

It’s an aluminum block from World Products, with a 41⁄2-inch bore and non-raised camshaft journal. With bushed lifter bores and enhanced oiling already integrated, nothing needs to change here. Many alcohol engines use a solid, Siamese-bore block, but since the Top Dragster Class is really a high-speed bracket class, where hot lapping is likely, we’ll stay with a water-cooled block.

The existing crankshaft is a 4340 forged piece from Crower, with a 41⁄2-inch stroke and 2.200-inch rod journals. It’s more than capable of handling the horsepower. The only change is that we need to add a second keyway slot for the blower hub. The 2.200-inch rod journals, along with the smaller big end of the steel rods, means no additional clearancing of the block is required for the larger stroke, and there are no rod-to-camshaft clearance issues.

The connecting rods from Crower are billet steel and measure 7.100 inches. The bearings are coated pieces from Calico. If we wanted to run a lot of rpm or run the boost into the stratosphere, we’d use aluminum rods since they cushion the bearings. But at a projected peak of only 7,000 rpm, and since we’re only using 10 pounds of boost, we’d rather not have to worry about the unpredictable life span of an aluminum rod. Rod bolts are unbelievably strong AMS5834 (Aerospace Material Standards) material. We like coated bearings, and used both normal and X bearings, (which are .0005 inch thinner), to allow for the extra coating thickness. That way you can mix and match to get the proper bearing clearances.

The connecting rods are by Crower and measure 7.100 inches. The bearings are coated pieces from Calico. The rod bolts are unbelievably strong AMS5834 (Aerospace Material Standards) material. We used bearings, which are .0005 inch thinner, to allow for the extra coating thickness.

The connecting rods are by Crower and measure 7.100 inches. The bearings are coated pieces from Calico. The rod bolts are unbelievably strong AMS5834 (Aerospace Material Standards) material. We used bearings, which are .0005 inch thinner, to allow for the extra coating thickness.

The N/A engine had a 10.7:1 static compression ratio. This is too high for a blown gasoline-fueled engine, but it’s perfect for alcohol (Methanol). Methanol will allow us to keep the compression ratio we already have. It will run cooler (when hot lapping), and will net a nice increase in horsepower with no other changes. Sure, there as some drawbacks to Methanol, but how much of what we have heard is myth versus reality? Later we’ll explore what it really takes to run methanol.

We are using pistons from Diamond Racing, and the final compression ratio will be 10.7:1. If we were starting from scratch, we would have ordered these pistons gas ported, but we’re reusing what we had from a previous build. Blown engines like gas porting to help with the ring seal, and it helps minimize blow-by. This is more critical with Methanol, as alcohol engines have a tendency to “milk the oil.” But lateral gas ports can be added, and while we’re at it, we’ll have Angie at Mopar Engines West coat the pistons as well.

If ordering new pistons was an option, we would probably move the rings lower on the piston, and might even use thinner rings to decrease friction. But since the pistons were already cut for 1⁄16, 1⁄16, 3⁄16-inch rings, we’ll use them as is. To help with blow-by, we’ll change to a ring set from Total Seal that consists of a gapless tool-steel top ring, Napier second, and a standard tension oil ring. Because of the wristpin location and the longer rod, we have to use an oil support ring too.

The pistons are from Diamond Racing, and the final compression ratio will be 10.7:1. We’re reusing what we had from a previous build. Lateral gas ports were added, and Angie at Mopar Engines West coated the pistons as well.

The pistons are from Diamond Racing, and the final compression ratio will be 10.7:1. We’re reusing what we had from a previous build. Lateral gas ports were added, and Angie at Mopar Engines West coated the pistons as well.

Foot note: Jumping ahead to the third article in this series, after testing this engine on the dyno and making several test-and-tune passes at the track, the amount of blow-by into the puke tank is minimal (about a tablespoon per pass), and the oil shows no sign of milking.

What is exotic are the head studs. We wanted to upgrade the head studs, since this block uses stock 7⁄16-inch diameter studs. ARP doesn’t sell a 7⁄16-inch upgrade kit, but you can buy each stud individually from ARP’s special division. The studs in the original Hemi kit have a tensile strength of 190,000 psi. We upgraded to studs made from L19 material, which increases the tensile strength to 260,000 psi.

Stage-V Millennium heads are great Hemi heads, which can flow over 500 cfm after CNC porting. They typically use the 10-bolt intake pattern, which allows opening the ports to massive levels. Normally, this head design requires using a custom intake manifold. But when this engine was originally built for use with pump gas, we wanted to leave the manifold options open. So we ordered the heads with the more typical 16-bolt pattern to alleviate spending a lot of money for a custom sheetmetal intake. We also ordered Stage-V’s additional spacer plates so that almost any intake manifold can be used. This sacrifices potential maximum performance, but it was a compromise we were willing to live with. The pump gas version used an Indy 4500-series manifold with a single 4500-style throttle body. The stainless steel valves are Ferrea, the springs are Pacaloy, and the retainers and locks are from Manley. These are great parts, but nothing you would consider exotic.

Stage-V Millennium heads can flow over 500 cfm after CNC porting. They typically use the 10-bolt intake pattern, but we ordered the heads with the more typical 16-bolt pattern. This mandated ordering additional spacer plates, so almost any intake manifold can be used.

Stage-V Millennium heads can flow over 500 cfm after CNC porting. They typically use the 10-bolt intake pattern, but we ordered the heads with the more typical 16-bolt pattern. This mandated ordering additional spacer plates, so almost any intake manifold can be used.

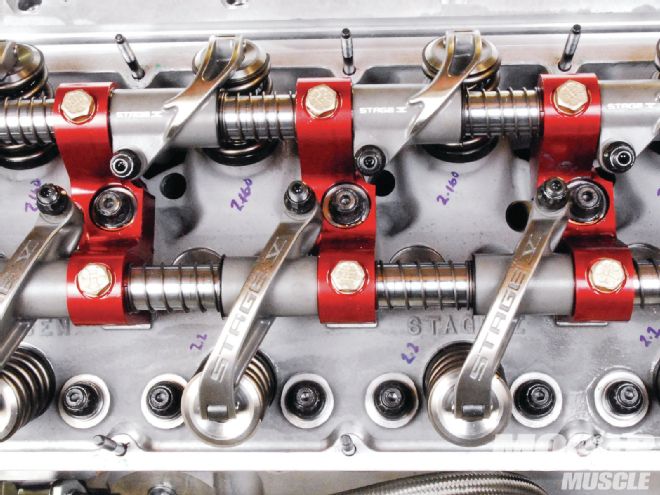

Hemi engines are notorious for working the valvetrain hard, so there are no cutting corners here. Stage-V provided the stainless-steel roller rockers and special stands for their Millennium heads. These rockers provide oil directly to the pushrod cups, so oiling through the pushrods is not required. Rocker shafts are upgrades (thick wall) from DeChellis Machine, and the camshaft and lifters are from Comp Cams. Camshaft specs are 280/288-degrees duration at .050 inch, with .720-inch lift at the valve, and a 112 lobe separation angle. This is the same camshaft that was used when the engine was normally aspirated, and it doesn’t really stress the valvetrain. The Pacaloy 1247 valvesprings have pressures of 300 pounds closed, 730 pounds over the nose, and are set at 2.075 inch installed height. These will hold things stable to over 8,000 rpm.

Stage-V provided the stainless-steel roller rockers and special stands for Millennium heads. These rockers provide oil directly to the pushrod cups, so oiling through the pushrods is not required. Rocker shafts are upgrades (thick wall) from DeChellis Machine, and the camshaft and lifters are from Comp Cams.

Stage-V provided the stainless-steel roller rockers and special stands for Millennium heads. These rockers provide oil directly to the pushrod cups, so oiling through the pushrods is not required. Rocker shafts are upgrades (thick wall) from DeChellis Machine, and the camshaft and lifters are from Comp Cams.

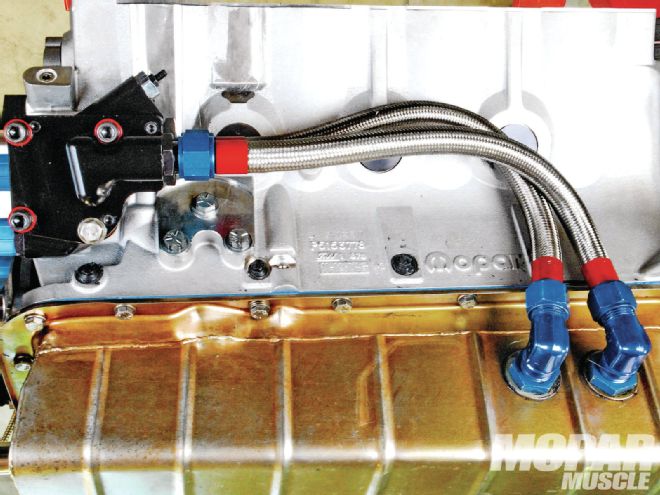

The oiling system is a 10-quart pan with a dual line and a swing-arm pickup, feeding a high-volume Titan pump and remote two-quart Wix oil filter.

The oiling system is a 10-quart pan with a dual line and a swing-arm pickup, feeding a high-volume Titan pump, and a remote two-quart Wix oil filter. Here’s a tip for you: If you pay attention to how you route the oil lines, you can consistently keep oil in the pump. That way, there are no dry starts.

The oiling system is a 10-quart pan with a dual line and a swing-arm pickup, feeding a high-volume Titan pump, and a remote two-quart Wix oil filter. Here’s a tip for you: If you pay attention to how you route the oil lines, you can consistently keep oil in the pump. That way, there are no dry starts.

This is a 16-bolt EFI manifold from Indy Cylinder Head. This engine will be injected, and we will be running injectors both above and below the blower. Injecting below the blower adds difficulty in regards to plumbing and tuning, but it pays dividends. It’s a world of difference on a street engine because of improved drivability. But, even on a race engine, it helps minimize distribution differences, and it increases charge density. The injected methanol that doesn’t go through the blower cools the intake charge rather dramatically. It’s like nitrous without the bottle.

The manifold is from Indy Cylinder Head. The engine features injectors both above and below the blower. This helps minimize distribution differences and increases charge density because the injected Methanol that doesn’t go through the blower cools the intake charge dramatically. Each injector flows 125 lb/hr for a total of 250 lb/hr per cylinder.

The manifold is from Indy Cylinder Head. The engine features injectors both above and below the blower. This helps minimize distribution differences and increases charge density because the injected Methanol that doesn’t go through the blower cools the intake charge dramatically. Each injector flows 125 lb/hr for a total of 250 lb/hr per cylinder.

Roots blowers displace a fixed volume of air per rotation, so a 572-inch Hemi is technically a little too large for a blower rated at 10-71. But we don’t need much boost to meet the goal, and we’re willing to overdrive it if need be. Besides, we already had the blower.

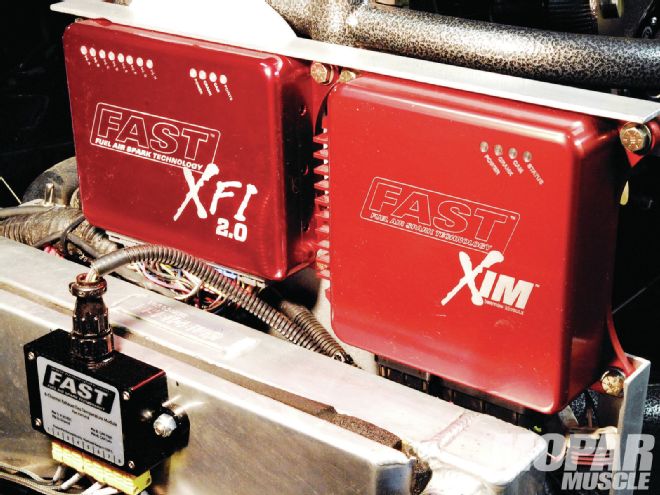

We chose the FAST XFI system with internal data logging. The internal data logging is needed, since there’s no way to carry a laptop in the dragster. The data log function is critical to view what the engine was doing during the pass, and see the actual A/F ratio every 1⁄10 second. There’s just no better way to tune an engine.

We chose the FAST XFI system with internal data logging. With this setup, we see the actual A/F ratio every 1⁄10 second. There’s just no better way to tune an engine.

We chose the FAST XFI system with internal data logging. With this setup, we see the actual A/F ratio every 1⁄10 second. There’s just no better way to tune an engine.

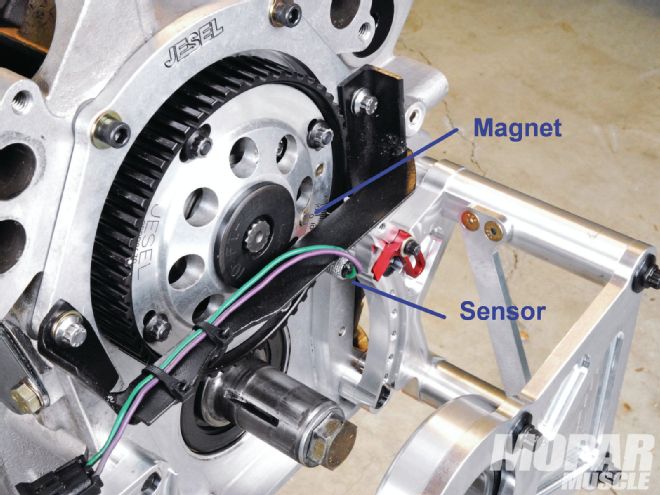

Since this engine doesn’t use a distributor, we used the FAST XIM ignition controller to drive the eight ignition coils. A distributor would work fine, but we did this to show that it could be done, and to minimize the electrical noise that could be created by the sparks inside the distributor cap. Sequential fuel injection and coil-near-plug operation both require a cam sensor, which was easy to acquire with the exposed Jesel beltdrive. This would also be a good test to see if the standard MSD LS-style coils have enough energy to fire the super-rich Methanol charge under boost conditions.

Methanol is almost an ideal race fuel since it carries some oxygen and cools everything it touches. About the only drawback is that it’s corrosive. This has to be considered, since contamination of fuel systems cannot be taken lightly. But if you do your homework, you can learn to not only live with it, but love it. Here are some characteristics and considerations:

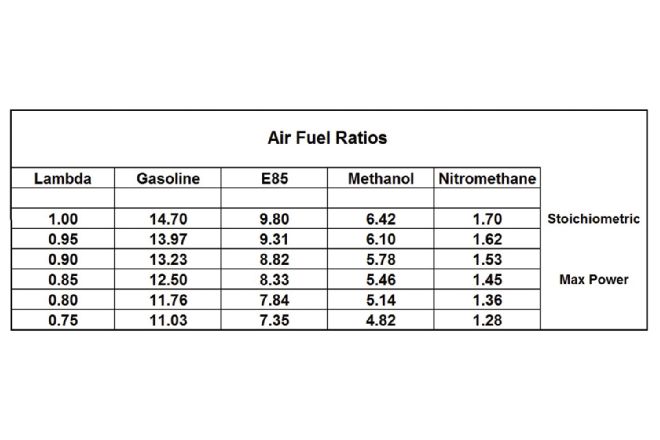

Here’s a chart to help explain the Stoichiometric A/F ratios and maximum power points for different fuels. Stoichiometric is the theoretically ideal air-to-fuel ratio, or as a scientist would call it, Lambda 1.0. Lambda 1.0 is the air/fuel ratio for engines that are running well under low to moderate loads, such as when cruising. But for maximum power, you have to be on the rich side of Stoich, usually 80 to 85 percent. The A/F fuel ratio for a normally aspirated Methanol engine under full load is around 5.4:1. Maxed-out blown alcohol engines often run all the way down to 4:1. We will use EGT sensors on the dyno to help decide what A/F ratio will be best for this engine, but our initial target will be 5:1.

Here’s a chart to help explain the Stoichiometric A/F ratios and maximum power points for different fuels. Stoichiometric is the theoretically ideal air-to-fuel ratio, or as a scientist would call it, Lambda 1.0. Lambda 1.0 is the air/fuel ratio for engines that are running well under low to moderate loads, such as when cruising. But for maximum power, you have to be on the rich side of Stoich, usually 80 to 85 percent. The A/F fuel ratio for a normally aspirated Methanol engine under full load is around 5.4:1. Maxed-out blown alcohol engines often run all the way down to 4:1. We will use EGT sensors on the dyno to help decide what A/F ratio will be best for this engine, but our initial target will be 5:1.

All of the fuel system components must be alcohol compatible. That should be obvious, but even the normal stainless steel braided hose is still just rubber hoses with a braided cover. You need to use hose that is rated for alcohol, such as Earl's PTFE-lined Ultra-Flex, and all fittings must be anodized. The fuel pump must be up to the task of not only the higher fuel pressure needed for EFI (greater than 43 psi), but also the higher volume requirement (2:1). Fuel filters cannot contain a paper element when using alcohol. Once complete, an alcohol fuel system will last for years. As an additional precaution, many racers add a lube to the Methanol, which coats aluminum surfaces. But some Methanol blends come with this additive already blended in.

As already stated, Methanol is a great fuel. If you didn’t change anything else, you would pick up about 10 percent in horsepower, and also gain consistency at the track. It has a very high latent heat property, which means it evaporates very quickly, and thereby cools everything it touches. This increases charge density and makes the engine less susceptible to detonation and environmental changes.

Sequential injection and coil-near-plug operation both require we use a cam sensor. This is easy to access with the exposed Jesel beltdrive.

Sequential injection and coil-near-plug operation both require we use a cam sensor. This is easy to access with the exposed Jesel beltdrive.

But your engine will consume twice as much as compared to traditional fuel. With a carburetor, this means you need to run huge main jets, which usually results in very rich idle conditions. With EFI, this can be controlled so that overly rich conditions don’t occur. Methanol engines are known to “milk the oil” (excess Methanol actually gets into the oil pan and makes the oil look like chocolate milk), but EFI can minimize that characteristic.

Methanol is very forgiving in regards to tuning. It has a much wider air to fuel ratio (A/F) range than gasoline. With a blown gas engine, the tune must be dead on, and would use a very high-octane (read: expensive) fuel. Methanol tolerates being on the rich side, and since it doesn’t produce carbon, it won’t foul plugs. You also won’t find an Octane rating for methanol, because of its different characteristics. Try building a blown gas engine that starts with a 13.0:1 static compression ratio. It’ll detonate and destroy itself during the first pass, but this is a normal, static compression ratio for a blown alcohol engine. Dynamic compression ratios with a boosted alcohol engine approach 30.0:1. So we have to change how we think about Octane and compression ratios when using Methanol.

For what it’s worth, many racers with a blown, alcohol engine don’t even know what their A/F is, since the only way to measure it mechanically is to weigh the fuel and the air (hard to do during a race). But a modern wideband O2 sensor works great to about 3:1 and it comes free with EFI. Wideband O2s are becoming more common in the racing world, but just like anything else, change takes time.

This is only the first of a three-part series that will show you exactly what goes in to building an injected and blown Hemi. This first installment covered the objectives, component selection, and design considerations. The second installment will cover the machining and assembly procedures, and show the differences from a “normal” street Hemi. Finally, in the third installment, we get this beast on a dyno, make some pulls, tune it, drop it in a car, and make some runs.

So we have our targets, and we have a handle on the rather interesting characteristics of Methanol as a fuel. Next month we’ll build this beast and see some special assembly techniques.

PRICE TAG

Part

Manufacturer

Part Number

Approx Cost

Block

World

088515-4500

$5,000

Heads

Stage-V

S-M2000H

$4,200

Crankshaft

Crower

95168

$1,500

Rods

Crower

B93911B-8-UPG

$1,600

Pistons

Diamond

Custom

$1,600

Coated Main Bearings

Fed Mogul

142M1

$150

Coated Rod Bearings

Calico/Clevite

CB743HN

$150

Cam Bearings

Dura-Bond

PDP-17T

$50

Camshaft

Comp

24-000-9

$380

Cam Drive

Keith Black

63107A +

$1,000

Lifters

Comp

829-16

$470

Rocker Arms

Stage-V

IR-417N3/ER-cus

$1,700

Rocker Shaft Supports

Stage-V

S-M2000ST

$900

Rocker Shafts

Dechellis Machine

I45-HB/E45-HA

$500

Pushrods

Smith Brothers8

NH314-CB

$300

Adjuster studs and nuts

Manton

Stud# 823, Nut# 851

$200

Oil Pump

Titan

426 drag

$800

Intermediate Shaft

Milodon

21525

$140

Oil Pump Internal Pickup

Milodon

21330

$130

Oil Pan

Milodon

31160

$375

Blower

Mooneyham

10-71

$2,500

Manifold

INDY

426-BM

$1,250

ECU

FAST

30-1004

$1,900

Harnesses

FAST

30-1100/1200

$600

Injectors

Lucas

621061

$880

XIM coil controller

FAST

30-1311

$600

Cam Sensor

MSD

2346

$80

Coils

AEM

30-2853

$640

Plug Wires

MSD

Custom

$150

Plugs

Champion

N59YDR

$40

Main Stud Kit

ARP

145-5602

$115

Rod Bolts

Crower

AMS5844

$400

L19 Head Studs

ARP

Special

$590

Valve Covers

Keith Black

53097FHA-1

$650

Water Pump

Meziere

WP337S

$430

Crank Support Cradle

RCD

202600-0004

$800

Total

$30,270