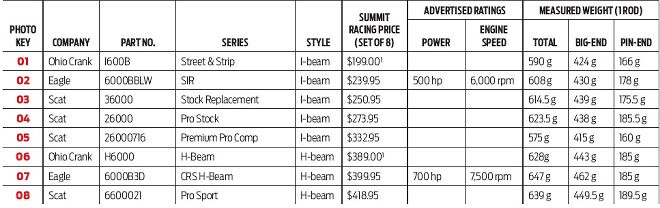

Even for a high-performance, street-engine rebuild, there's just no excuse for messing with old-school factory connecting rods anymore. Aftermarket rod prices have declined, and you can get superior small-block Chevy forged rods that are better than those old stockers in every way: They're lighter, made from better materials, and held together by better bolts. Modern forging and machining techniques now yield closely-weight-matched rods, allowing rod manufacturers to eliminate the cumbersome (and space-consuming) old-school balancing pads found on factory muscle car–era rods. And when purchased as a set, no balancing is needed.

A typical machine shop might charge $230 to $250 to refurbish a set of eight small-block Chevy factory rods for an entry-level hot rod engine. That price typically includes magnetic particle inspection (aka Magnafluxing), installing new quality ARP rod bolts (another $60 or more), resizing the big-ends, and bushing the pin end for floating pins (which, by the way, is the standard method for getting the stockers' center-to-center lengths close on a blueprinted engine). Ideally, none of the rods will be cracked or bent, and the huge balancing pads on the old-school rod will have enough meat to enable weight-matching the set, especially if one of the original rods required replacement. Clearing those potentially huge pads itself requires additional piston clearance, which makes for a heavier, taller piston. The taller pistons, plus the funky nut-and-bolt rods, introduce yet more clearance problems on stroker engines. Get 'er all done, you're still stuck with a 5.7-inch center-to-center stocker, but many engine builders now prefer at least a 6.00-inch rod for use with today's increasingly popular stroker combinations.

Duttweiler Performance checked the big and pin ends on its Sunnen Rod Hone machine. The checking mandrel was set to the minimum spec for the big end and then to the small-block Chevy's 0.927-inch piston pin size for the small end. The big end was checked by rotating the rod around the three-fingered checking mandrel to obtain an overall reading. Only one rod proved out of round.

Duttweiler Performance checked the big and pin ends on its Sunnen Rod Hone machine. The checking mandrel was set to the minimum spec for the big end and then to the small-block Chevy's 0.927-inch piston pin size for the small end. The big end was checked by rotating the rod around the three-fingered checking mandrel to obtain an overall reading. Only one rod proved out of round.

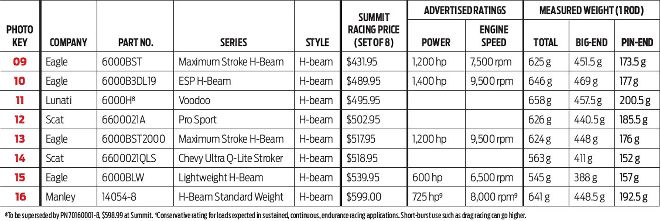

By contrast, aftermarket, entry-level, 6.00-inch rods bushed for floating pins are available for as low as $200 per set, and even trick H-beam rods are offered in a variety of options for less than $600 a set and are, in some instances, advertised as supporting 1,000 hp or more. We know this because we ordered up a representative sampling of 6.00-inch small-block Chevy rods from Summit Racing (thanks, Summit!) and direct-sales outfit Ohio Crankshaft, then measured, analyzed, and photographed the lot with the assistance of Duttweiler Performance, BHJ, and FH Pumps. When all was said and done, we found, in nearly all cases, the rods were accurately machined in critical areas. About the only required end-user rework would be honing the pin end to your preferred pin-clearance specification.

Even if sticking with tried and true 5.7-inch rods, otherwise equivalent rods to those we examined would be slightly cheaper yet. As usual, Summit's pricing is virtually unbeatable, usually much lower than the manufacturers' retail pricing.

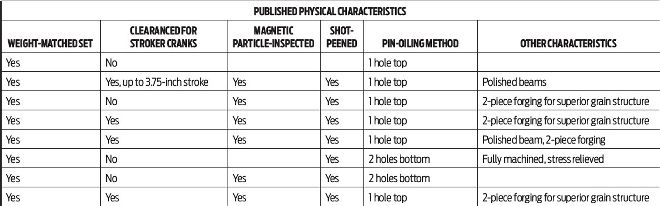

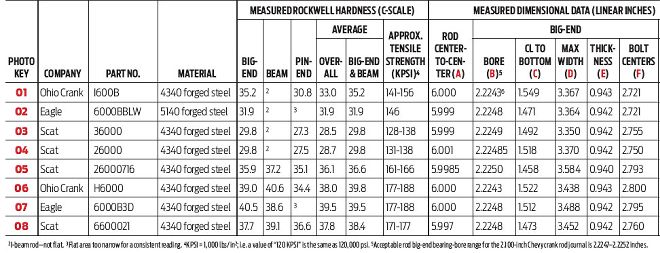

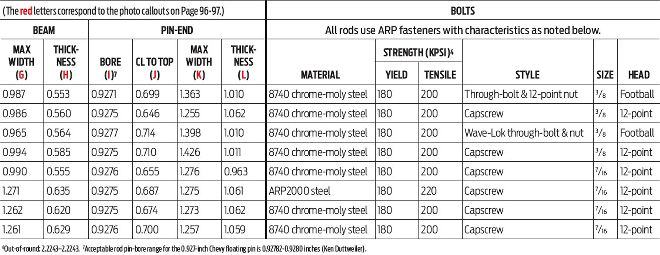

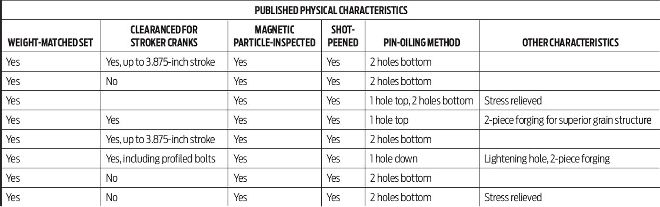

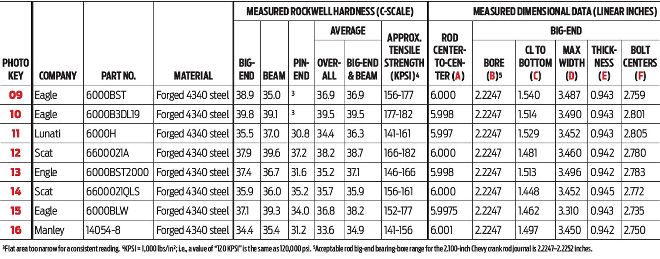

For a detailed breakdown on what we found, see the photos and spec charts on the following pages, followed by a detailed summary of what it all means. The rods on the following pages are presented in order from the least expensive to the most expensive, at the time we priced them from Summit Racing and Ohio Crankshaft. Listed are the basic material and physical configuration of the rods and rod bolts, actual measured dimensional information, and principle manufacturers' published data.

What the Specs Mean

Duttweiler Performance checked the big and pin ends on its Sunnen Rod Hone machine. The checking mandrel was set to the minimum spec for the big end and then to the small-block Chevy's 0.927-inch piston pin size for the small end. The big end was checked by rotating the rod around the three-fingered checking mandrel to obtain an overall reading. Only one rod proved out of round.

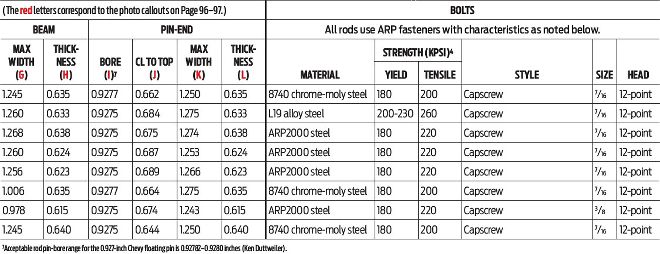

On the previous pages are a bunch of arcane numbers and specs. Here's what they mean. Any red callout letters refer to the specific dimensions listed in the large photo on the opening page and in the charts.

Rod materials: Even at the less-than-$600 level, almost all the rods are made from premium 4340 forged steel, although one entry-level rod is forged from 5140. Either material, when properly prepped and heat-treated, is much better than original small-block Chevy 1053 forged steel rods (or the later powdered-metal design). However, while the four-number steel alloy designator accurately describes the material's basic chemical composition, it does not account for the materials' purity, number of occlusions, or grain structure. There are several different grades of the same alloy; the higher the level, the greater the purity. There is no way for the end user to actually judge the "level" or "quality" of the material short of sectioning the rod and sending it out to a special lab for detailed analysis. According to rod expert Jack Sparks, the grade or purity is one of the main differences between the entry-level rods and the $1,000-plus rods.

FH Pumps' Bob Lucey weighed the rods on its digital Fairbanks scale. The I-beam rods were generally lighter than H-beam rods, but several of the more sophisticated lightweight H-beam rods were lighter than any of the I-beams. The setup here with the pin-end support is for weighing the big end.

FH Pumps' Bob Lucey weighed the rods on its digital Fairbanks scale. The I-beam rods were generally lighter than H-beam rods, but several of the more sophisticated lightweight H-beam rods were lighter than any of the I-beams. The setup here with the pin-end support is for weighing the big end.

Power and rpm capability: Of the rod brands we analyzed, Eagle and Manley are the only manufacturers that publish official claimed power and rpm capabilities. At best, these are only an approximation, with rpm being more critical. Other rod makers maintain that rpm, crank stroke, piston weight, and number of cycles, as factored into a very complex equation, or, better yet, actual physical cycle and bending tests are the only ways to establish a rod's true fatigue life and failure point. That requires very specialized laboratory-quality testing.

Weight: The weight (in grams) is important when balancing the rotating assembly. The manufacturers claim their sets are all weight-matched. We weighed only one individual rod of the same part number. When selecting the rods for your application, note that some rods specifically trade ultimate power capability for less weight.

Rockwell hardness: A material’s Rockwell value roughly correlates to its tensile strength. We tried checking the rods multiple times on both sides of the big end, the beam, and the pinhole, then averaged the results. Unless the I-beam rod’s side-beam area is polished, it is not flat enough to yield a reliable Rockwell number. Likewise, some rods’ pinholes had insufficient flat-surface area to obtain a reading. We found the heat treating for any given rod fairly consistent, although some rods seemed slightly softer at the pin end than on the big end; this may be an actual deformation of the relatively thin surface in the pin area when hit by the Rockwell tester’s diamond tip rather than a true hardness measure. Generally, one would expect less than a one-point variation throughout the entire rod. Jack Sparks says stock-type rods should yield a Rockwell number in the high 20s on the C-scale; entry-level performance rods around 32–36; and higher-end 4340 rods around 38–41.

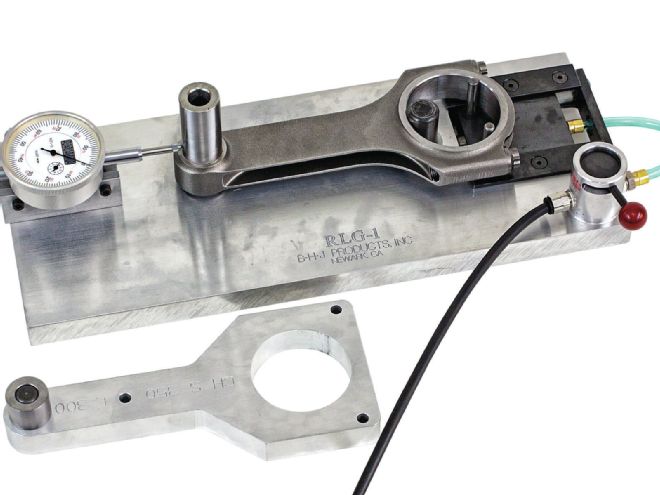

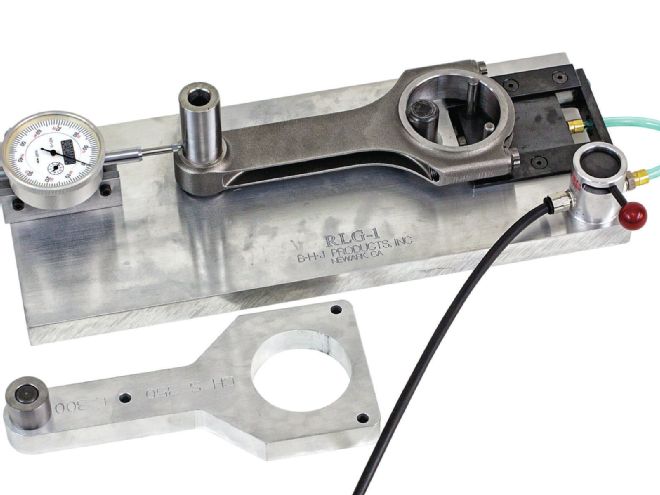

Center-to-center length was checked with BHJ's shop air–powered rod-length gauge (PN RLG-1). The dial indicator is first zeroed using an application-specific length standard or a rod with a qualified length. Rods are checked on the fixture with the wristpin installed (undersize pins are available for press-fit rods). The wristpin is swept past the dial indicator to obtain a plus/minus reading from zero.

Center-to-center length was checked with BHJ's shop air–powered rod-length gauge (PN RLG-1). The dial indicator is first zeroed using an application-specific length standard or a rod with a qualified length. Rods are checked on the fixture with the wristpin installed (undersize pins are available for press-fit rods). The wristpin is swept past the dial indicator to obtain a plus/minus reading from zero.

Bolts: ARP rod bolts were used exclusively on all the rods. This company has a reputation for quality and consistency, and the fact that just about every rod maker uses ARP fasteners to hold the rods together ought to tell you something. There are at least three different levels of ARP bolts, and even the “entry-level” 8740 alloy steel fastener is light years stronger than original factory bolts and even the rod material itself. You rarely see rod-bolt failures anymore if the bolts are properly installed and preloaded. Optional upgraded ARP2000- or ARP L19-alloy bolts generally add about $80 to $90 to an otherwise identical rod set at Summit.

Center-to-center length (A): This is the blueprint length from the center of the big end to the center of the pin end. For these rods, it should be 6.0 inches exactly. Consistent rod lengths are important when decking to minimum to achieve the exact same piston deck height (of course, the crank indexing and stroke as well as the piston pin centerline-to-block deck dimensions must also be consistent). BHJ is not just about torque plates and balancers. It has all sorts of neat machining and checking gauges; we used its connecting rod-length gauge to measure the rods. None of the individual rods we checked were longer than 6.001 inches or shorter than 5.99 inches. We also checked a complete set of identical rods, and as a group, they varied less than 0.003 inch. A high-end ($1,400) set of Crower rods was checked just for kicks and on average they deviated less than 0.001 inch.

The Wilson 2000-series Rockwell tester forces a diamond tip against a flat surface to measure the amount of pressure needed to make an impression on the material. The Rockwell C-scale is used for steel alloys, and the number generated by the impression roughly equates to the material's tensile strength. Most of the rods Rockwelled in the mid-to-high 30s (about 156,000 to 177,000 psi).

The Wilson 2000-series Rockwell tester forces a diamond tip against a flat surface to measure the amount of pressure needed to make an impression on the material. The Rockwell C-scale is used for steel alloys, and the number generated by the impression roughly equates to the material's tensile strength. Most of the rods Rockwelled in the mid-to-high 30s (about 156,000 to 177,000 psi).

Big-end bore (B): This is the rod-journal bore size, which should range from 2.2247–2.2252 inches for the 2.100-inch-od small-block Chevy rod journals. All rods checked were close to the minimum dimension; that's desirable to achieve today's preferred tight bearing clearances. Besides, you can always hone the journal if necessary. Only one rod was actually out of round.

Big-end centerline to bottom (C): This is both an indication of material thickness at the bottom of the rod and how well it might clear the oil pan or bottom of the cylinder in a critical stroker application. A thicker rod made from the same material should be stronger, but it's also heavier and takes up more space. None of the rods have old-school big balancing pads.

Big-end max width (D): This is the widest part of the big end, generally from the outside of one bolt boss to the opposite boss. Wider means stronger, but added material adds weight, and in some cases, there may be less clearance to the pan rails. In the same vein, capscrew rods have more clearance and offer better load retention than nut-and-bolt rods.

Big-end thickness (E): This the fore-and-aft rod width as viewed from the side when installed on the journal. A thicker rod should have less side clearance. We found nearly all rods to be fairly consistent, at about 0.942–0.943-inch thickness. One ultralightweight Scat rod was slightly thinner.

Rod bolt center-spacing (F): Ken Duttweiler says that if the rod bolts are spaced more widely, given the same bolt and similar parent material, increased spacing should make for a stronger rod overall (but again, slightly heavier).

Rod beam max width (G): This is the rod's max width. I-beam rods have a narrower width than H-beam rods. Within a given rod crosssection (H- or I-beam), thicker generally means stronger if the material strength and hardness is the same--but that means it's also heavier.

Rod beam thickness (H): This value is the beam thickness as viewed from the side. I-beam rods are thinner than H-beam rods.

Pin-end bore (I): Duttweiler likes to see 0.92782–0.9280 inches with a 0.927-inch floating pin. We found all the bores undersize, which at least lets the builder hone to his preference.

Pin centerline to top (J): This references material thickness and how far above the pin centerline the rod extends, offering an indication of how much clearance above the rod is required when ordering custom pistons. None of the rods had balancing pads, which means any custom piston can be shorter and lighter.

Pin-end max width (K): Again, this indicates material thickness and required piston clearance. In the case of unpolished I-beam rods, this includes any forging flash. You could gain a little clearance here by polishing the rod.

Pin-end max thickness (L): This provides a clue as to whether the rod will fit between the piston's inner pin bosses.

Pin oiling method: Floating pins require pin oiling. There are two methods: one hole drilled from the top down, or two drilled on each side from the bottom up. There is no consensus on which is better. Lunati covers its bases by drilling all three holes.

HRDP-121200-CONROD-096-103-

HRDP-121200-CONROD-096-103-

HRDP-121200-CONROD-096-103-

HRDP-121200-CONROD-096-103-