Maximizing bang for the buck comes down to making the most of a given combination of parts. When it’s done right, the engine will throw down power numbers that belie its modest parts list, packing a heavyweight punch in an unassuming package. This small-block Mopar from SKMFX Engines is a testament to that ideal, with righteous output from commonplace parts. This engine was built for competition in the Street Division of our annual engine building competition, the AMSOIL Engine Masters Challenge. Jesse Robinson and his teammates from SKMFX Engines assembled this bullet as a backup engine to compete in place of their big-block, which was held up by part delivery delays. The stout output from this very basic production-based combination was impressive.

Starting with a production Chrysler 360 LA-Series small-block, the bottom end was filled with basic parts that are more than up for performance use. An Eagle stock-stroke crank is spun by stock-length Scat I-beam rods, with KB Icon forged pistons providing the shove. The block received a partial fill in the water jackets to better support the cylinder walls.

Starting with a production Chrysler 360 LA-Series small-block, the bottom end was filled with basic parts that are more than up for performance use. An Eagle stock-stroke crank is spun by stock-length Scat I-beam rods, with KB Icon forged pistons providing the shove. The block received a partial fill in the water jackets to better support the cylinder walls.

Basic Bottom End

SKMFX started with an ordinary production “LA-Series” Mopar 360 block, and proceeded with a bottom end build that would be typical of any budget street effort. The block received basic prep, including a .060-inch overbore, line honing, and decking. Robinson also added a short fill to the water jackets: “I’m a big believer in the short fill, and I like what it does to the water and oil temperatures. The exposed cylinder ends up at about 4 inches, and it stiffens the cylinder walls considerably,” Robinson says. The block also had the main oil feeds enlarged to 9⁄32 inch, but was otherwise stock in terms of the lubrication system.

Filling the block is a rotating assembly based on the stock 360’s 3.58-inch stroke. Rather than using the stock cast-iron crank, Robinson selected an Eagle 4340 steel crank. “This crankshaft is a good value for the price at under $600,” he says. “One of the major hiccups with the 360 is the external balance. A few years ago, I had a stock 360 crank internally balanced and it cost as much as this Eagle crank because it took six slugs of Mallory metal to balance it. At that point it makes sense to move to the steel.” The rods are a set of Scat I-beams in the stock 6.123-inch length. Robinson explains this choice: “I don’t like the H-beams for many applications; they are just too heavy. These Scat I-beams are just a beautiful set of connecting rods, and a great value for the money.” Filling the cylinders is a set of KB Icon pistons and Perfect Circle rings. The internal parts combination seemed to follow the theme of budget-oriented replacement parts that are proven durable in a high-output application.

The stock production main bearing caps were retained, though high-strength ARP main studs provide extra clamping. Jesse Robinson from SKMFX tells us the factory 3.58-inch stroke is far easier on the bottom end assembly than a long-armed stroker.

The stock production main bearing caps were retained, though high-strength ARP main studs provide extra clamping. Jesse Robinson from SKMFX tells us the factory 3.58-inch stroke is far easier on the bottom end assembly than a long-armed stroker.

Topping It For Power

The KB icon pistons are wrapped with a conventional Perfect Circle 1⁄16-1⁄16-3⁄16 ring pack. The most exotic part of the ring package is the Napier-faced second ring, which aids in oil control. Bearings are coated Clevite pieces.

The KB icon pistons are wrapped with a conventional Perfect Circle 1⁄16-1⁄16-3⁄16 ring pack. The most exotic part of the ring package is the Napier-faced second ring, which aids in oil control. Bearings are coated Clevite pieces.

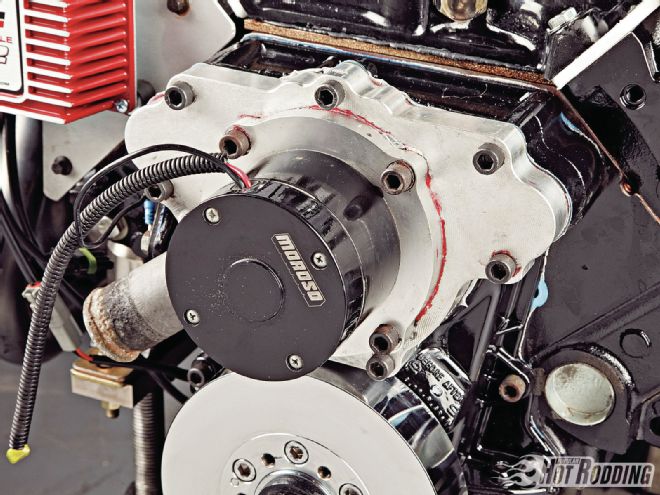

A similar approach followed up to the top of the engine with the EngineQuest Iron Magnum 318B cylinder heads. These heads are designed as production replacement units for the OEM Mopar Magnum heads, but are revised with the earlier “LA-Series” intake manifold bolt angle. The castings are significantly improved compared to the factory units with both durability and performance in mind. Robinson’s experience with the EngineQuest cylinder heads has been overwhelmingly positive: “I started using EQ heads on Chevrolets, using their Vortec heads on 350 and 383 Chevys, and the results were never disappointing. I started to experiment with the Dodge heads, and again they produce very good power.”

The EQ heads on this particular engine were the subject of considerable development work at SKMFX. Robinson explains: “I got to work pretty extensively in the cylinder heads. I got away from the factory 8mm stem valves, and went to 11⁄32-inch because it opens up far more selection in off-the-shelf valves. I went with Manley Severe Duty intake valves in a 2.08-inch diameter, with a 5.250-inch length. A part of the puzzle that predicated how I built the heads was coming across a set of secondhand unused T&D rockers. I put the bedplate on the Magnum pedestals, and selected the valve length to best suit the geometry with the rockers. These EQ cylinder heads are nice to work with, having plenty of metal for porting. I put them on the CNC mill and wrote a program to open the bowl out to a venturi shape, and with this mod alone the port went to 273 cfm. I put the valve job on it and hand-blended the machine work, and then put it on the CNC again to open up the intake side of the port. After hand-finishing the port work and many trips from the cutting bench to the flow bench, I ended up with 300 cfm at .600-inch lift.”

The EngineQuest cylinder heads were the subject of an impressive development effort. Robinson wrote a CNC program to cut the bowls and port runners, and hand-finished the ports and chambers. Final combustion chamber volume measures 59 cc.

The EngineQuest cylinder heads were the subject of an impressive development effort. Robinson wrote a CNC program to cut the bowls and port runners, and hand-finished the ports and chambers. Final combustion chamber volume measures 59 cc.

On the camshaft, the custom COMP hydraulic roller cam actually uses slightly less duration on the exhaust side than on the intake. Part of this is because of the very high exhaust flow from the EQ heads. “The exhaust side has very high flow; it can get to around the 200-cfm level with very little work. I found on the other EQ head builds and the W2 head builds I’ve done in the past, that I’m over-exhausting the engines. My VE numbers will be over 100 percent from the bottom of the pulls to the top, and the power doesn’t really correspond with those kinds of efficiency numbers, so I’m led to believe that I’m blowing everything out the exhaust. I took one stab at the camshaft, and I don’t think I was too far off the mark, since on my dyno the engine was producing over 510 lb-ft of torque at the peak.” The cam features 246/244 degrees duration, using the more aggressive COMP SPTK lobes on the intake side, and the milder HRR lobes on the exhaust. Lift is .648 inch with the 1.5:1 ratio rockers, while the lobe separation angle is 106 degrees. The cam was installed at an intake centerline angle of 102 degrees.

A characteristic of the Magnum-style heads is outstanding exhaust flow. Robinson relates that there is a danger of over-scavenging the engine. With the exhaust flow in mind, the cam was spec’d with a milder lobe and less duration on the exhaust side.

A characteristic of the Magnum-style heads is outstanding exhaust flow. Robinson relates that there is a danger of over-scavenging the engine. With the exhaust flow in mind, the cam was spec’d with a milder lobe and less duration on the exhaust side.

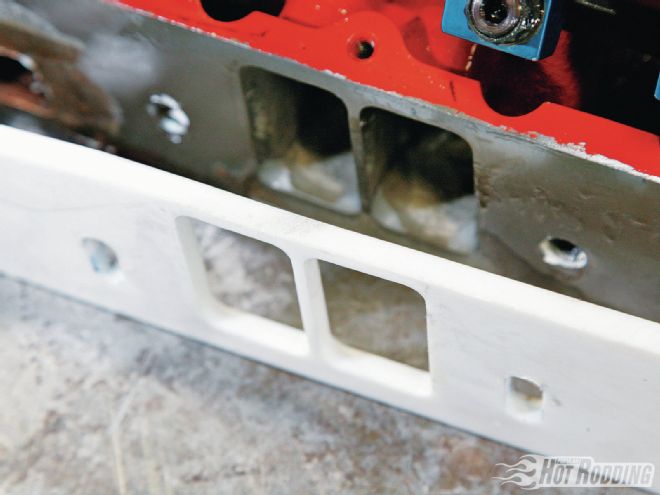

The engine uses a Weiand X-celerator intake manifold, but Robinson tells us that he thinks there was room for improvement in the induction. “It was the only manifold I had at the time, and I figured I would just put it on if the output looks like it is within reason. I had the heads flowing around 300 cfm, and with the intake on it the intake port flow dropped to around 230 cfm. I experimented with custom runner extensions in the plenum, but they ended up hurting power everywhere. I actually cut them back out, and put in much more conservative extensions.” Topping the manifold is a Holley 750 HP. Robinson spoke highly of this unit: “What can I say about the Holley HPs? The 750 HP seems to be the one to buy if you want to have just a spectacular carburetor out of the box. I did not modify it; I just calibrated the air bleeds and jetting.”

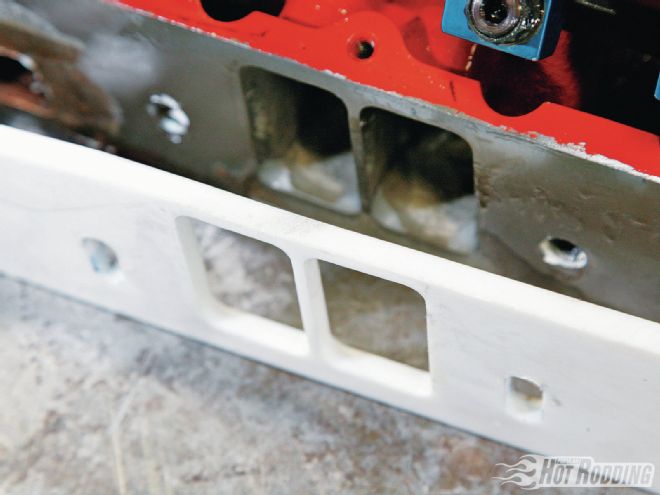

As run in the competition, the intake ports posted a peak flow of 300 cfm at .600-inch lift. A thick Teflon intake gasket was CNC cut at SKMFX to insulate the induction system from engine heat.

As run in the competition, the intake ports posted a peak flow of 300 cfm at .600-inch lift. A thick Teflon intake gasket was CNC cut at SKMFX to insulate the induction system from engine heat.

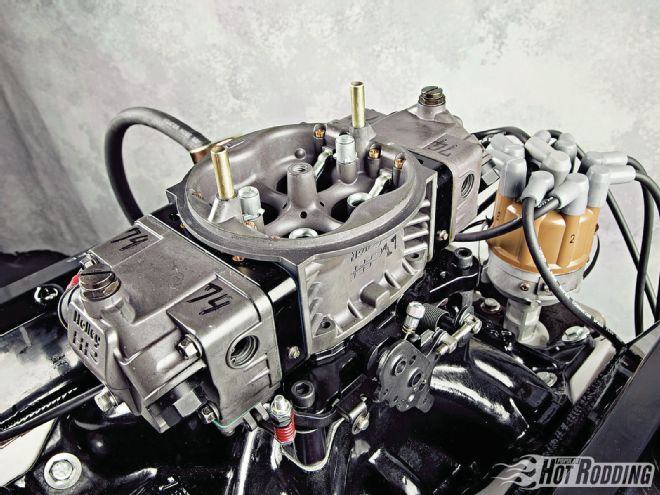

Taking advantage of a production oddity, the engine is fitted with a factory Chrysler Lean-Burn distributor. These distributors featured no advance curve or vacuum advance. As Robinson puts it: “Coupling the locked-out production distributor with the programmable curve of a MSD 6AL2, is a match made in heaven.” Rounding out the engine package is a pair of Schoenfeld stepped headers with 1⅝- to 1¾-inch primary tubes. Up front, a CAT crankshaft damper handles the vibes, while a custom billet water pump housing crafted at SKMFX accepts a Moroso big-block Mopar electric water pump.

Providing the air/fuel mixture is a Holley 750 HP-Series carb. Robinson tells us these are outstanding carburetors at this power level and displacement. The carb was run as-delivered with the exception of routine calibration changes.

Providing the air/fuel mixture is a Holley 750 HP-Series carb. Robinson tells us these are outstanding carburetors at this power level and displacement. The carb was run as-delivered with the exception of routine calibration changes.

At the AMSOIL Engine Masters Challenge, Robinson and the SKMFX team put on a very respectable performance with their budget combination, showing a peak of 515 hp in qualifying with their stock-stroke iron-headed Mopar, while running on VP100 fuel. What was even more impressive was the very fat torque curve, exhibiting over 400 lb-ft at just 2,500 rpm, with max torque swelling to 495 lb-ft at a 4,800-rpm peak. These would be decent numbers for a mildly built stroker combination, and the output is exceptional for an engine with production-style heads. As Robinson explained: “I’ve done a few stroker 408s, and you need a lot of cylinder head for that engine. Most guys don’t have that budget, and with budget cylinder heads I like the power curve of the smaller stock-stroke engines.” Thinking about how sweet an engine with this power curve would run on the street, we can’t argue with that point.

A nice custom touch on this engine is the SKMFX-fabricated billet electric water pump housing. The housing accepts a compact Mopar big-block electric water pump.

A nice custom touch on this engine is the SKMFX-fabricated billet electric water pump housing. The housing accepts a compact Mopar big-block electric water pump.

Heads For Power

The ignition system on the small-block Mopar was primarily made up of MSD components, with the exception being a rebuilt factory Chrysler Lean-Burn distributor, which has no timing advance. The MSD 6AL2 handled the ignition curve.

The ignition system on the small-block Mopar was primarily made up of MSD components, with the exception being a rebuilt factory Chrysler Lean-Burn distributor, which has no timing advance. The MSD 6AL2 handled the ignition curve.

EngineQuest Magnum Heads

The EngineQuest (EQ) cast-iron Magnum cylinder head is an iron replacement head that delivers a surprising punch at an affordable price. These heads offer an improved alternative to stock with better flowing intake and exhaust ports for enhanced horsepower and torque. The castings feature a 172cc intake runner volume, with 62cc combustion chambers. The heads are cast in Australia, using a casting technique that produces an exceptionally smooth port surface for more flow and power. Used in box-stock form, these heads offer superior quality at an affordable price with no additional machining, porting, or polishing required.

The EQ Magnum cylinder heads are available for both the factory LA-series and later Magnum Mopar small-block engines. EQ’s part number CH318B head is machined with the LA-series–style intake pattern, while EQ’s part number CH318A features the vertical ’92-04 Magnum intake pattern. Both cylinder heads are built to accept the OEM Magnum-style valvetrain and rockers.

Besides the improved ports and flow, EQ has improved on the factory Magnum design with a thicker deck for added strength, added hardened exhaust seats for greater resistance to cracking, and redesigned the water flow system for improved thermal conductivity. With CNC-machined guides and seats, a superior port finish for increased flow, and a three-angle valve seat, EQ’s cylinder heads offer the best of both worlds—OE fit and greatly improved durability and performance. Each head is individually subjected to a rigorous 25-point inspection to ensure a quality product. For more information about EQ’s Magnum cylinder heads, phone 800-426-8771 or visit www.EngineQuest.com

For a largely production-based engine configuration, this small-block Mopar delivered healthy output, posting 515 peak horsepower at 6,000 rpm, while 495 lb-ft of twist was recorded.

For a largely production-based engine configuration, this small-block Mopar delivered healthy output, posting 515 peak horsepower at 6,000 rpm, while 495 lb-ft of twist was recorded.

By The Numbers

371ci Mopar Small-Block

Bore:

4.060 inches

Stroke:

3.58 inches

Displacement:

371 ci

Compression ratio:

11.3:1

Camshaft:

COMP Cams hydraulic roller

Camshaft duration:

246/ 244 degrees at .050-inch tappet rise

Valve lift:

.648 inch

Rocker ratio:

T&D 1.5:1 ratio

Piston rings:

Perfect Circle 1⁄16-1⁄16-3⁄16

Piston:

KB Icon

Block:

Mopar 360 LA, production

Crankshaft:

Eagle

Rods:

Scat I-beam

Cylinder head:

EngineQuest Magnum

Intake valve diameter:

2.08

Exhaust valve diameter:

1.60

Intake manifold

Weiand

Carburetor:

Holley 750 HP

Header:

Schoenfeld stepped primary

Ignition:

MSD 6AL2

Damper:

CAT

Fuel:

VP Racing VP100

At the 2011 AMSOIL Engine Masters Challenge, the SKFMX crew included Jesse Robinson, Joe Rutters, and Ron Maclean.

At the 2011 AMSOIL Engine Masters Challenge, the SKFMX crew included Jesse Robinson, Joe Rutters, and Ron Maclean.

RPM TQ HP 2,500 401.5 191.1 2,700 408.4 202.1 2,900 426.2 235.3 3,100 429.6 253.6 3,300 430.8 270.7 3,500 425.3 283.4 3,700 431.3 303.8 3,900 444.9 330.4 4,100 461.2 360.0 4,300 473.9 388.0 4,500 486.1 416.5 4,700 493.7 441.8 4,800 495.0 452.4 4,900 494.3 461.1 5,100 491.9 477.7 5,300 485.9 490.4 5,500 480.7 503.4 5,700 470.9 511.1 5,900 458.4 515.0 6,000 450.9 515.1 6,100 441.5 512.7 6,300 424.1 508.7 6,500 402.9 498.6