Displacing just 385 cubes, this Chevrolet engine combination from Hinkle Performance Engines produces a remarkable 736 hp. The secret is the SB2.2 cylinder heads and a host of surplus NASCAR parts stockpiled by Hinkle as race teams switched engine types.

Displacing just 385 cubes, this Chevrolet engine combination from Hinkle Performance Engines produces a remarkable 736 hp. The secret is the SB2.2 cylinder heads and a host of surplus NASCAR parts stockpiled by Hinkle as race teams switched engine types.

While hot rodding was growing up in the Western United States, starting out on the dusty dry lakes in California and evolving onto quarter-mile dragstrips, a parallel hot rodding movement was growing up in the South, fueled initially by the practicalities of moonshine profits and developing onto the circle tracks of stock car racing. While there were similarities, the Southern boys were building engines and parts to go the distance, with endurance as much a part of the formula as explosive power. The round track racers were developing their own breed of performance parts. NASCAR today remains among the most popular of racing venues, with mega-teams putting vast resources into race car development. Engine programs have always been a big part of looking for the winning edge, and these competitors chew through high-end engine components like nobody’s business.

Hinkle selected a GM Bow Tie block from his stack of former NASCAR goodies to use as the foundation for this build. The Bow Tie is a conventional small-block Chevy layout, but is much beefier than any production block.

Hinkle selected a GM Bow Tie block from his stack of former NASCAR goodies to use as the foundation for this build. The Bow Tie is a conventional small-block Chevy layout, but is much beefier than any production block.

Needless to say, much of that NASCAR pro racing hardware eventually filters out of those secretive racing engine shops and into the secondhand market. With the state of the art constantly changing, yesterday’s parts are of little use to these guys. In NASCAR country, the volume of parts going into those engine programs is essentially matched by the amount of stuff shoved out the back door to make way for the latest hardware. Buck Hinkle, who runs Hinkle Performance Engines with his son, Clark, may never have been involved with the shine-running roots of NASCAR’s early days, but the man can build an engine, and he can drive. Of Buck’s many racing accomplishments, he held the record at his local track, Illiana Motor Speedway in Crown Point, Indiana, in the 100-lap Tony Bettenhausen Memorial Race. Set back at the 1968 race, the record stood for an astonishing 40 years, with Hinkle running a big-block ’64 Chevelle convertible on a ’57 Chevy “Black Widow” chassis.

Similarly, the pistons are NASCAR units, these being billet JE pieces. Buck picked up a pallet of surplus pistons at a local auction at a rock-bottom price. The lot included many sets of pistons that had never been run.

Similarly, the pistons are NASCAR units, these being billet JE pieces. Buck picked up a pallet of surplus pistons at a local auction at a rock-bottom price. The lot included many sets of pistons that had never been run.

The Build

Hinkle is now a regular competitor at the AMSOIL Engine Masters challenge, fielding engines built in their shop in London, Kentucky. For the 2011 event, Hinkle Performance Engines looked to NASCAR hardware to field an entry in the new Xtreme Division of competition. Hinkle had accumulated a vast stock of ex-NASCAR components, and set out to build an SB2.2 Chevy combination based mainly on parts he had on hand. The build started with a GM Bow Tie block, which was required to meet the production base and internal oil pump requirements of the EMC rules. These are dedicated racing blocks, but faithfully follow the original small-block Chevrolet architecture, while the SB2 blocks are made for external dry-sump oiling systems and have an altered lifter bore position. The block was a used race piece, and as such was already beefed for endurance applications, with massive billet four-bolt splayed main caps in all five bearing locations.

Another nod to low parasitic losses and light weight in the piston design is the inboard piston pin boss machined for a .750-inch diameter pin. Buck offset bushed the Carrillo rods to meet the small pin diameter and also dial-in the deck height for the piston/rod/stroke combination.

Another nod to low parasitic losses and light weight in the piston design is the inboard piston pin boss machined for a .750-inch diameter pin. Buck offset bushed the Carrillo rods to meet the small pin diameter and also dial-in the deck height for the piston/rod/stroke combination.

The plan for filling the block centered upon coming up with a combination that would take advantage of some of the high-end NASCAR components Hinkle already had in stock at his shop. Among these were a set of Carrillo connecting rods, and a set of new, in-the-box JE billet pistons. The pistons were built for a small .750-inch piston pin, while the 6.2-inch rods were .866 inch at the small end. This gave Buck the opportunity to adjust the rod length slightly while bushing the rods by offsetting the location. Taking into account the desired crank stroke, the compression height of the pistons and the deck height of the block, the bushings were offset to a finished rod length of 6.175 inches. An Eagle forged crank completed the rotating assembly. To match the rods, the crank was cut down on the rod journals to the 1.88-inch Honda journal diameter of the connecting rods. The crank was finished with a stroke of 3.510 inches, which along with the 4.175-inch bore resulted in the final engine displacement of 385 ci.

The very robust billet-steel splayed main caps were already fitted to the Bow Tie block. Buck Hinkle tells us that upgraded main caps were a routine installation for engines used by professional race teams.

The very robust billet-steel splayed main caps were already fitted to the Bow Tie block. Buck Hinkle tells us that upgraded main caps were a routine installation for engines used by professional race teams.

These internal components, from the small journals and piston pins, to the narrow-section Total Seal ring package featuring .031-inch compression rings and 1.5mm oil rings, are all designed for light weight and low friction. Hinkle found the rings, which work in conjunction with gas ports in the pistons, sealed well. The rods are pin-guided, which means that the running alignment of the piston/rod assembly is maintained by the piston at the pin, rather than at the connecting rod big-end cheeks, as is common with a production engine.

Buck selected his piston and rod combination, and built the engine combination to work around those components. The connecting rods are NASCAR Carrillo units, while the bearings are Speed-Pro.

Buck selected his piston and rod combination, and built the engine combination to work around those components. The connecting rods are NASCAR Carrillo units, while the bearings are Speed-Pro.

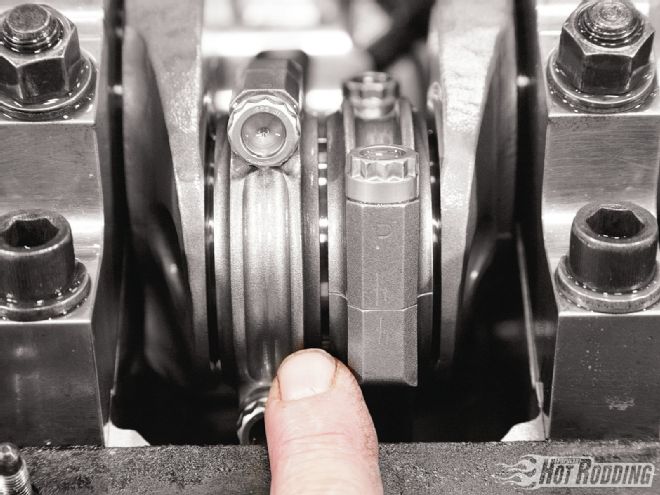

Expanding on the pin-guided assembly, Buck tells us: “It gives you less friction because the rods don’t touch anything; they are just floating on the crankshaft. They don’t touch the side of the crank, and they don’t touch the other rods, because the rods are really narrow. If you look at the side clearance, you have about .100 inch between the side of the rods and the crank, and .100 inch between the rods. You would think the oil pressure would go away, but it doesn’t. It hardly affects the oil pressure if you have the bearings right. The other thing it does, assuming everything is straight as far as machine work, is it keeps the piston exactly centered in the bore as the rod spins around. The rod isn’t pushed to one side by the other rod or the side of the crankshaft. That centers the ring-and-piston assembly as it goes up and down in the bore.”

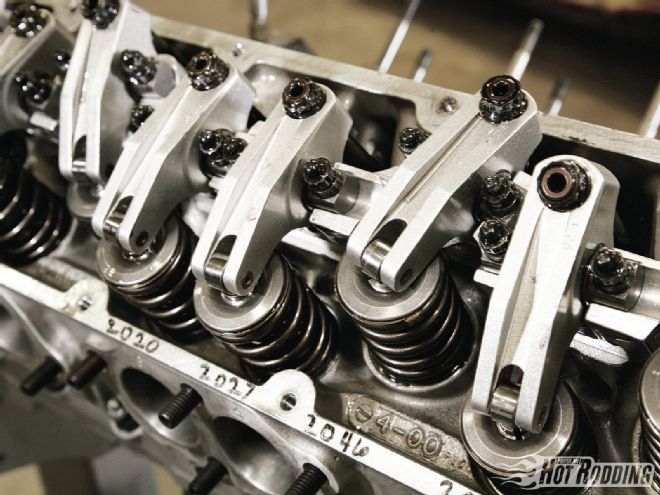

With the bottom end buttoned up with a standard Melling Chevy oil pump and a wet sump oil pan fabricated from a steel dry-sump pan, the rest of the engine combination came down to the cam and valvetrain and top end components. Buck bushed the lifter bores to fit the .875-inch Crower solid roller lifters. These Crower lifters feature a .180-inch offset on the intake side, which helps the geometry by putting the pushrod in better alignment with the rockers. To maintain low-end torque and meet the 7,500-rpm limit of the competition, Hinkle was relatively conservative when ordering the custom COMP solid roller cam. Specs on the cam are 249/253 degrees duration at .050 on a 108-degree lobe separation angle, with .756-inch gross lift delivered by the 1.75:1 T&D rocker arms. Buck relates: “It wasn’t really a big camshaft, but we were trying to get the torque down at the bottom. Everyone said to me that the SB2 doesn’t put out the torque, but I found out different.” The dyno results showed very strong torque right from the bottom of the test range at 3,500 rpm.

Unlike a production engine in which the rod’s big-end cheeks keep the piston aligned in the cylinder bore, the Hinkle engine is piston-guided, using a precision side clearance at the small end of the rod. Buck tells us this arrangement reduces drag and keeps the piston straight in the bore. Note the large side clearance at the rod’s big end.

Unlike a production engine in which the rod’s big-end cheeks keep the piston aligned in the cylinder bore, the Hinkle engine is piston-guided, using a precision side clearance at the small end of the rod. Buck tells us this arrangement reduces drag and keeps the piston straight in the bore. Note the large side clearance at the rod’s big end.

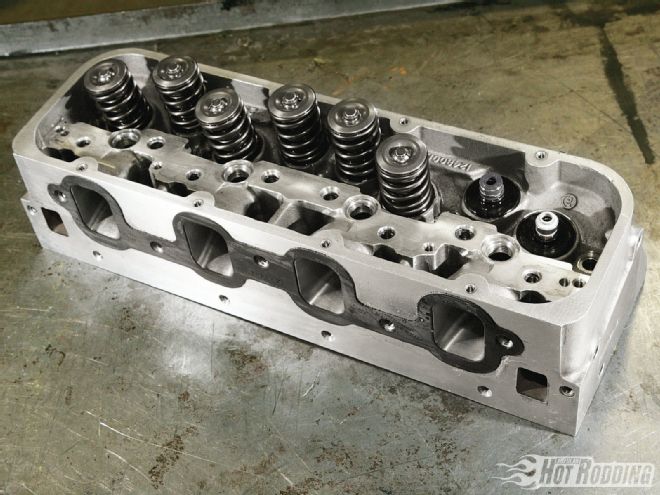

Up top, the cylinder heads are a key component in making serious power. The SB2.2 heads are a purpose-built race head and take advantage of a completely revised port and valve layout compared to a traditional Chevy small-block. These heads are former NASCAR units, and Hinkle Performance has had plenty of experience with the setup, building a number of these engine combinations for customers’ street cars. The heads were ported by Clark, showing 402 cfm on the intake side at just .700-inch lift. Buck explains: “I try to get the flow through the midrange as best I can—that’s where the valve is working the most. We used a 55-degree intake seat, with titanium Del West valves, a 2.160-inch intake valve, and 1.600-inch exhaust valves.” Buck considers the SB2 cylinder head an exceptional piece: “The way the heads flow and the combustion chambers are designed just works. When I dyno test those things they are just a step above any other small-block head you can put on; they just kind of explode with power once they come on.”

The pistons were built with grooves to take a very narrow .031 ring profile, which were filled with a set of Total Seal rings. The narrow rings create minimal drag, and Buck tells us that despite the narrow rings, the oil control and compression seal were exceptional.

The pistons were built with grooves to take a very narrow .031 ring profile, which were filled with a set of Total Seal rings. The narrow rings create minimal drag, and Buck tells us that despite the narrow rings, the oil control and compression seal were exceptional.

Working with the cylinder heads is an Edelbrock single-plane manifold. This top end combination uses a separate valley plate with divorced runners in a separate spider assembly. As with the cylinder heads, Clark handled the porting on the manifold, working the full length of the runners and modifying the plenum form. This manifold is designed for a standard 4150 carb flange, and to run with a 1050 Dominator’s 4500 flange, an adapter from HVH was used. The HVH adapter features a tapered form below the throttle plates that improves the transition beneath the large bores of the Dominator carb.

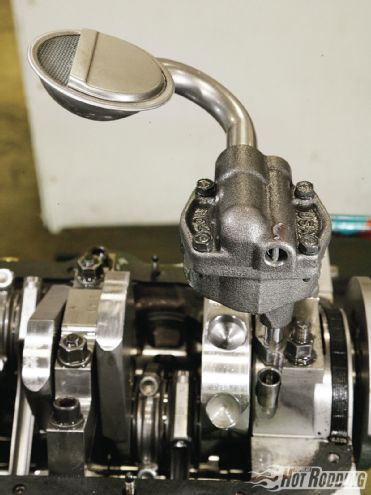

Unlike some of the later dry-sump–only Chevrolet race blocks, the Bow Tie block comes with provisions for a standard small-block Chevy oiling system. The oil pump is a standard Melling replacement.

Unlike some of the later dry-sump–only Chevrolet race blocks, the Bow Tie block comes with provisions for a standard small-block Chevy oiling system. The oil pump is a standard Melling replacement.

Finishing the assembly is a set of Schoenfeld sprint car headers, featuring 1¾ to 1⅞ stepped primary tubes. Buck spoke highly of these headers: “I think Schoenfeld is one of the best header manufacturers in the United States. We use them on all the round track motors around here.” Providing the fire is a complete MSD ignition system, using an MSD billet distributor, a 6A ignition box, and a Blaster II coil along with MSD wires. Buck explains that the MSD ignition components have served him well. “I use the MSD on the dyno and on the cars we run. I’ve never even had a box go bad. I kept it simple with a regular distributor.”

Hinkle’s engine was assembled just in time to make it to the 2011 Engine Masters Challenge competition, with little time for testing. Buck elaborated: “I just got it together and really didn’t have time to try different parts combinations—it was run just how I first assembled it. I did have a few things that could have been tested, like a set of higher ratio rockers, and running even more compression. In the end, I think we missed the tune-up as far as air/fuel ratio on the carb, and it hurt the power output, but it still delivered good power.” With peak power coming in at 736 hp at a reasonable 7,000 rpm, and nearly 600 lb-ft of torque on hand from just 385 cubes, there is little doubt of the power capability of these racetrack engine components.

The real secret to this engine’s outstanding power production are the GM SB2.2 cylinder heads. These are dedicated race castings with a completely revised port and valve layout. Clark Hinkle’s port work put the flow at 400-plus cfm at .700-inch lift.

The real secret to this engine’s outstanding power production are the GM SB2.2 cylinder heads. These are dedicated race castings with a completely revised port and valve layout. Clark Hinkle’s port work put the flow at 400-plus cfm at .700-inch lift.

Where Do I Get Some?

It’s no secret that the big boys in pro circle track racing chew through top-shelf parts like no other group in racing. In fact, as the state of the art or specs change, entire engine programs are liquidated to make way for new parts. Many of the parts used by Hinkle Performance Engines in building this SB2.2 Chevy were scooped up at local auctions, often held in Southern states. The auctions are where some unbelievable bargains can be found, however, items are often sold in bulk lots for local pickup. Much of this stuff is bought by outlet dealers who sell the bulk lots off piecemeal. These sellers and their inventories can be found with a little Google searching with keywords such as “used,” “NASCAR,” “engine,” and “parts.” You may not get rock-bottom auction prices, but the prices are generally a fraction of retail.

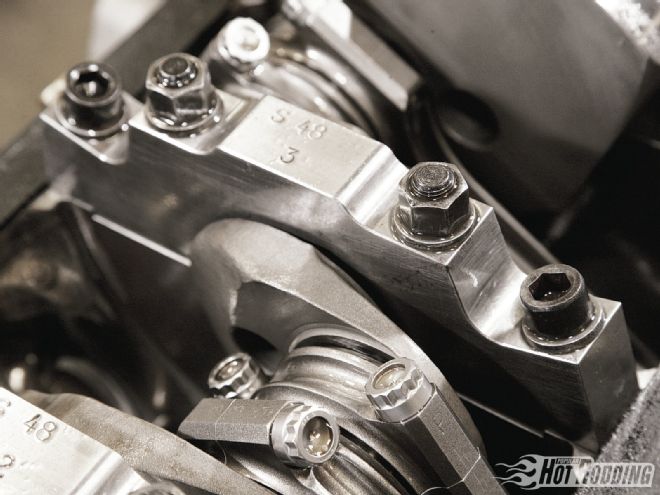

A dedicated rocker arm arrangement is required for the SB2.2 heads, and it is unlike anything you’ll see for a standard Chevy small-block. The rockers come from T&D, with a ratio of 1.75:1. The Hinkle crew also had a set of 2:1 ratio rockers, but time constraints did not allow testing the increased ratio.

A dedicated rocker arm arrangement is required for the SB2.2 heads, and it is unlike anything you’ll see for a standard Chevy small-block. The rockers come from T&D, with a ratio of 1.75:1. The Hinkle crew also had a set of 2:1 ratio rockers, but time constraints did not allow testing the increased ratio.

For those outside NASCAR country, many of these parts filter into more mainstream sales venues, such as eBay.com, or listings on RacingJunk.com. In fact, most racing and enthusiast message boards have parts listing pages where a variety of these parts come up. Enthusiasts can take advantage of a direct pipeline from Roush-Fenway and other top NASCAR teams by checking out the offerings at RoushYatesParts.com. They have stepped up with over 40,000 square feet of warehouse space stocked with inspected and cataloged used racing parts. This huge inventory of used racing parts is listed at very reasonable prices, with shipping available worldwide.