There are few things that make a street rodder’s life more miserable than a car that runs hot. A cooling system that belches steam like a locomotive or pukes the proverbial green river of death is not only annoying but is sure to shorten engine life and pretty much put the kibosh on any long-range traveling plans you may have.

To keep the 409 in our Road Tour ’55 Chevy cool, we had Joe Shinliver of Woody’s Hot Rodz install an aluminum, triple-pass, cross-flow radiator from Don Armstrong’s U.S. Radiator.

To keep the 409 in our Road Tour ’55 Chevy cool, we had Joe Shinliver of Woody’s Hot Rodz install an aluminum, triple-pass, cross-flow radiator from Don Armstrong’s U.S. Radiator.

When it comes to our Road Tour cars we simply can’t afford downtime that results from overheating problems, so to eliminate any possibility of engine temperature issues we routinely turn to Don Armstrong of U.S. Radiator. The company has been in business for over 50 years, and Armstrong has been there for 40 of them. He began as a delivery driver, worked in every facet of the operation, and now owns the place. Today under his leadership the company produces over 400 different radiators.

While Armstrong has years of experience and does constant research to stay up with the latest cooling system technology, he has one other unique asset—he’s a hard-core hot rodder who understands the challenges of keeping them cool. As he explains it, the core design not the material had the greatest effect on temperature drop.

U.S. Radiator has a radiator for virtually any application; this is an aluminum down-flow for a ’32 Ford.

U.S. Radiator has a radiator for virtually any application; this is an aluminum down-flow for a ’32 Ford.

While all radiator cores might look the same they perform vastly different based on tube spacing and fins per inch. The heat transfer points of a radiator are where temperature is actually allowed to leave the radiator and that occurs where the fins are bonded to the tubes. The more transfer points a radiator has the greater the temperature drop will be between the inlet and outlet. For comparison a ’60s-style core typically had tubes spaced 1/2-inch apart, that is 1/2-inch of fin between the tubes. By going from a two-row radiator to a four-row core design we were able to double the heat transfer points, which resulted in a 15-20 percent increase in temperature drop without changing the other variables, such as air or coolant flow.

U.S. Radiator offers four distinct core designs, the Standard that is found in most OEM-style radiators, the High Efficiency aluminum with 20 percent more heat transfer points, the High Efficiency copper/brass with 20 percent more heat transfer points, and the Optima copper/brass that uses 1/4-inch tube spacing with 1/4-inch fins that provides 40 percent more heat transfer points

Everything is built in-house at U.S. Radiator. These are the headers that are attached to the cores. Note they accept three rows of tubes.

Everything is built in-house at U.S. Radiator. These are the headers that are attached to the cores. Note they accept three rows of tubes.

Radiator materials have created quite a bit of controversy. In the ’80s, the Japanese came out with a core design in response to the need to downsize radiators that have become the standard in the industry because it was efficient enough to allow the re-introduction of aluminum (a less-efficient heat transfer material) at the OE level. By changing the tube spacing to 3/8-inch, a core design referred to as High Efficiency in the industry, more tubes or water passages and fins were allowed across the face of a core with a specific width in inches. The design was simple enough but proved to be very efficient in that more heat transfer points created greater temperature drop inlet to outlet. It should be pointed out that the move to aluminum radiator construction was purely financial. The raw materials necessary to build a radiator are purchased by the pound and a finished aluminum radiator weighs about 25 percent of a copper/brass unit (dollars per pound being almost equal at that time). The result was a huge financial savings for the car companies.

When it comes to the difference in performance between copper/brass and aluminum radiators you may find the tests by U.S. Radiator surprising. They found that temperature drops at all operating ranges was virtually the same, with a slight advantage going to the copper/brass unit. But consider this: the thermal conductivity or heat transfer rate of copper is 92 percent versus aluminum at 49 percent. However, the copper fin is bonded to the tubes or water passages using lead solder, which is very inefficient and slows the heat transfer rate to just slightly better than that of aluminum. This can be a disadvantage if the bonding process doesn’t allow the copper fin to touch the brass tube and why not all copper/brass cores of similar design but different manufacturers transfer heat equally. Copper/brass radiators because of their weight and durability have been around a long time and are easily disassembled and reassembled for cleaning purposes. Not the case with aluminum unless speaking of the OE version that comes with crimp-mounted plastic tanks. As a result the life expectancy of the aftermarket aluminum radiators will be far less than that of copper/brass.

These are tubes for a copper/brass radiator. They are pre-coated with a thin layer of solder.

These are tubes for a copper/brass radiator. They are pre-coated with a thin layer of solder.

The Triple flow Option

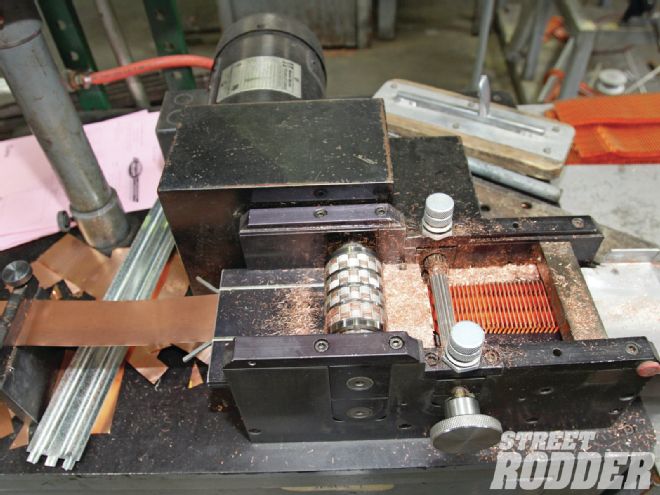

This machine turns sheets of copper into the fins that will be placed between the tubes. The fins actually have tiny louvers to increase efficiency.

This machine turns sheets of copper into the fins that will be placed between the tubes. The fins actually have tiny louvers to increase efficiency.

This unique design re-routes the coolant back and forth through the radiator core multiple times. As a result, the coolant travels further through the core and is exposed to more airflow and coolant temperature can be dropped 15-20 percent.

Cooling System FAQs Courtesy of U.S. Radiator

Q What are recommended engine-operating temperatures?

A Most hobbyists aren’t concerned with fuel efficiency so our recommendation would be 175 to 195 degrees F. Higher operating temps will burn fuel more efficiently but the increase in operating pressure and metal distortion can easily create problems over time.

Q Do you recommend internal or external transmission coolers?

Tanks are also stamped in-house.

Tanks are also stamped in-house.

A External transmission coolers are preferred to keep unnecessary heat out of the radiator.

Q How does radiator core thickness effect cooling?

A An increase in thickness over a stock application allows for greater fin bond surface and therefore greater temperature drop. When going from a two- to a four-row, for example, you double the fin bond or heat transfer points. The increase however isn’t one to one because the transfer efficiency of the trailing rows is adversely affected by the increase in air temperature from the previous rows and the decrease in air velocity caused by the increased thickness.

Q Do you recommend mechanical or electric fans?

This is just a small sample of the variety of tanks kept on hand. Note the rolls of raw material in the background.

This is just a small sample of the variety of tanks kept on hand. Note the rolls of raw material in the background.

A We always say, why rely on another operating system if you don’t have to? Mechanical fans turn when the motor turns. However, we highly recommend a shroud properly fitted to the fan and radiator. The only time you really depend on a fan is at idle or low speed where there is little or no air flowing through the grille. Shrouds are necessary to maximize the amount of ambient air being pulled through the grille and radiator. For the record, proper fan and shroud alignment should be leading edge one-third in and trailing edge of the fan two-thirds out. The airflow off the back of the fan deflects at about a 45-degree angle when set this way. When the blade extends further into the shroud the air off the back of the blade flows straight back into the block and decreases the airflow efficiency by about 15 percent.

That being said, if an electrical fan is the only way to go then by all means place it on a shroud that covers the entire core. We often see an electric fan attached directly to the core and the only thing this does is waste the rest of the core surface when you need it the most. A 16-inch electric fan attached to a core only cools a 16-inch circular section of that core. Where space is an issue, U.S. Radiator offers a 3/4-inch-deep aluminum shroud that enables adequate airflow over the entire core and when combined with a thin-line electric fan results in a total depth of 2-3/4 inches.

Shown here is a tank for an aluminum radiator. Note the baffle as this one is for the Triple Flow option.

Shown here is a tank for an aluminum radiator. Note the baffle as this one is for the Triple Flow option.

Q How much pressure should the cooling system be under?

With the fins and tubes in a fixture the headers are installed.

With the fins and tubes in a fixture the headers are installed.

A Cooling system operating pressures are largely determined by water pump operating pressures and we prefer to keep it under 1 pound. We all know by increasing the system pressure by 1 pound we increase the boiling point by 3 degrees, so by running a 12-pound cap our water won’t boil until it gets to 248 degrees F, and an engine that wants to run at 248 degrees F will open that cap up long before it gets that hot. To deliberately increase the operating pressure to increase cooling is redundant in my opinion and again only points out the need for more efficient heat transfer.

Keep in mind, pressures will increase in the system just after turning off the engine as the coolant absorbs existing engine heat but can’t move through the radiator to dissipate it. The resulting increase in pressure pushes coolant past the cap and hence the need for a coolant recovery system. Once the coolant in the idle engine starts to cool, a vacuum is created and another valve in the cap opens and prevents the radiator from collapsing a top tank but more importantly returns the coolant to the radiator so no outside atmosphere or air (contamination) enters the sealed system. Unfortunately most aftermarket recovery tanks are smaller than the needed capacity and that varies with cubic inches and size of the engine.

Once the header is in place this roller is used to make sure the openings in the ends of all the tubes are uniform.

Once the header is in place this roller is used to make sure the openings in the ends of all the tubes are uniform.

Q How is the size of radiator determined?

Clamped in a fixture, the core assembly is sent through an oven, which melts the solder on the tubes securing them to the fins.

Clamped in a fixture, the core assembly is sent through an oven, which melts the solder on the tubes securing them to the fins.

A There are formulas to determine appropriate radiator size based on engine heat output (operating Btu’s) and radiator heat transfer rates (also stated in Btu’s). They can be found in any engineering handbook but my recommendation to a hobbyist is to put in the most efficient radiator that fits the hole or intended application, up to a four-row copper/brass or two-row aluminum core. I think everyone knows by now that copper/brass units use 1/2-inch tubes while aluminum uses 1-inch tubes. That way the thermostat or lower limit control can maintain the lowest temperature you’ve determined best for all driving conditions.