The guru of all gurus in carburetor function was without a doubt an obscure Dutch-Swiss dude named Danny. OK, his full name was Daniel Bernoulli and it’s possible you may have heard of him. Besides being an uber-smart mathematician/statistician/physicist/author, he put into words the theory of why carburetors work. Of course, unless you are also an über-smart physicist, you might not get all the little details and decipher the squiggly lines in his writing. That means that when it’s time to bolt a brand-new, shiny fuel mixer on your bitchin 383 with double hump heads and three-quarter race cam, you’re better off talking with the tech guys at the company you bought it from in order to get it running to the best of its ability. PHR recently spoke with the top techies at Holley, Quick Fuel Technology, and Edelbrock in order to glean their most helpful hints and help you avoid the most common mistakes. In no particular order are the most common problems and suggested solutions.

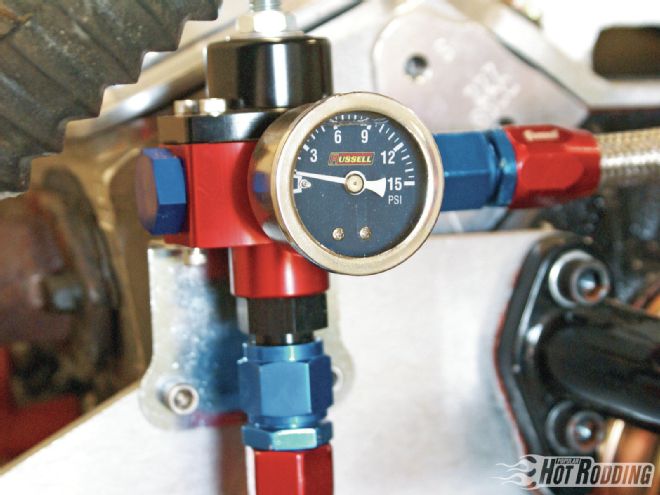

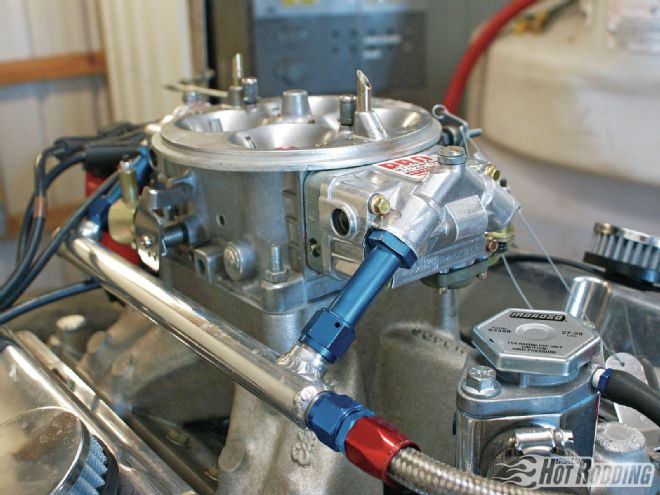

Number One: Incorrect Fuel Pressure

Surprisingly, the most common problem with getting a carb working right is not having the correct fuel pressure. Quick Fuel Technology tech expert Zach Baker says: “These carbs are designed to run at 6.5 psi. You might be able to get away with 7, but we’ve had a rash of pumps that do 8 or 9 pounds, which is great from a volume standpoint of getting fuel to the front of the car, but the carburetor’s not going to be happy there so you have to run a fuel pressure regulator and a lot of people just don’t.” The head of Edelbrock’s tech department, Dave Stinson, recommends a regulated pressure of 5 to 5.5 psi on their carbs, with a max of 6.5 psi.

Number Two: Wrong Carb Size

Choosing a 1,050-cfm Dominator for a 327-cube engine might impress the guys at the local car show, but it is a surefire recipe for a poor-running engine, unless it’s designed to turn 9,500 rpm. Kevin Baker: “If you’ve got a 500ci engine and all you’re going to do is fire it up, back it out of a trailer, and cruise it down to the Dairy Queen to light the tires off, you don’t need a 1,000-cfm carburetor to do that. A smaller carburetor will drive better.” Also, there is no truth to the myth that you can jet a carb from a 750 to an 850, or anything like that. The sizing is determined by the airflow through the venturi, boosters, and baseplate, not the fuel jets.

Number Three: Wrong Carb Design

Typical four-barrel carburetors are set up as either square-bore or spread-bore design. The square-bore carbs have equally spaced and sized throttle bores while spread-bore carbs have two smaller primary bores and two larger secondary bores. As you may know, or would expect, there are intake manifolds designed for each of these. Adapters are available to allow cross breeding of square-bore carbs to spread-bore manifolds, and vice versa. Edelbrock’s Stinson says: “If the customer has a spread-bore like a GM intake that a Q-jet came off of, we’d recommend a number 2697 adapter kit.” It’s important to know that if you have a car with a low, flat hood, you may need to check hood clearance.

Number Four: Let Your Buddy Tune Your Carb

He may be just as excited as you are with your new purchase, but before you let him loose with a box of jets and a flat-blade screwdriver, note how good his car drives and how long it took him to get it that way. He may indeed be an expert, but odds are slightly against it. A quick telltale sign of whether he knows his stuff is whether or not he has a full box of assorted jets, air bleeds, squirters, pump cams, vacuum gauge, and diaphragms and if he knows what the heck they are. If he’s only messed with Holley-style jets, he might not know what to do with Edelbrock-style metering rods.

Number Five: Jump In & Make Big Changes

You may have decided that your buddy doesn’t know squat and you have a better chance of getting it right. Good for you! Now don’t blow it by thinking that jetting the carb the same as the guy in your car club who “runs real fast” will make your ride fly. Slow down and RTFI (that’s Read The Friendly Instructions.) It goes against car-guy mantra but instructions are not meant to be thrown away. They have (and we’ve read them all) very good details on how to get your carburetor running well. Once you’ve read them, go online and search the manufacturer’s websites for tech info and tuning instructions. Edelbrock.com and HolleyTV.com both have an amazing series of carburetor short movies showing everything from basic installation, to jetting, to advanced tuning techniques.

Number Six: Neglect Vacuum Hookups

Often, factory engines are designed with what appears to be a spaghetti factory for vacuum lines. Some of those are critical, and some aren’t. Either way, mark every single one of them prior to removing your old carb, and look at their function. Keep an eye out for which vacuum lines use ported (to distributor) vacuum and full manifold vacuum. On the other end of the spectrum, if the car is destined for racing only, QFT’s Zach Baker says: “I see people run PCV valves on motors that have huge-by-large camshafts in them. They just don’t work that well. It’s an emissions piece and not a performance piece.” Look for an alternate means of removing crankcase pressure.

Number Seven: Wrong Engine Combination

While not technically a carburetor problem, choosing the wrong camshaft, intake, compression, or exhaust will often result in the car owner pointing the finger at the new shiny thing on top that’s easy to get to and adjust. No amount of carb tuning can fix a poor engine combination. The best you can hope for is masking the problem slightly. The best fix is a preemptive one. Call the tech lines for the carb and cam companies to be sure the combination is copacetic.

Number Eight: Incorrect Ignition Advance

Again on the edge of being called a “carb” problem, but what we’ve learned is that most carb problems aren’t really carb problems at all. If there is insufficient ignition advance, a carb will act lazy and rich, often leading to the tuner leaning out the idle mixture as a bandage when correcting the timing will result in a much better fuel and power curve.

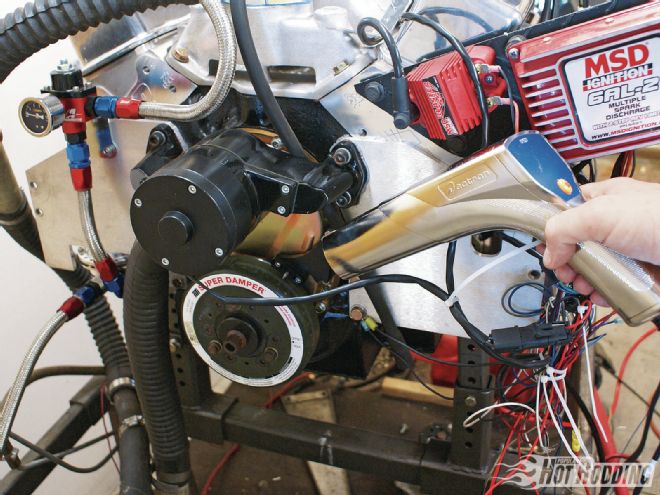

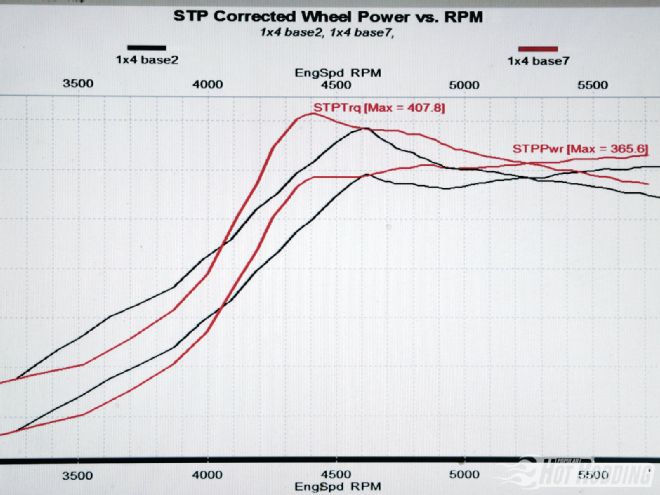

Number Nine: Don’t Use A Dyno To Power Tune

Seat-of-the-pants tuning—and even dragstrip tuning—can only get you so close to the optimal power on a street car. If you want to get the most out of your street car and you don’t mind spending a few hundred dollars on dyno time, a chassis dyno (go eddy current, not inertial—we like SuperFlow or Mustang) will get you maxed out. Make sure they have a wideband air/fuel ratio data logger and someone with a good track record of dyno tuning carbs. In this Westech dyno session of the ’75 Laguna project car with the original solid-roller 408ci small-block, we gained 12 rear-wheel horsepower by checking and adjusting the throttle linkage for max opening, then leaning it out four secondary jet sizes to put us at a solid 12.8:1 air/fuel ratio.

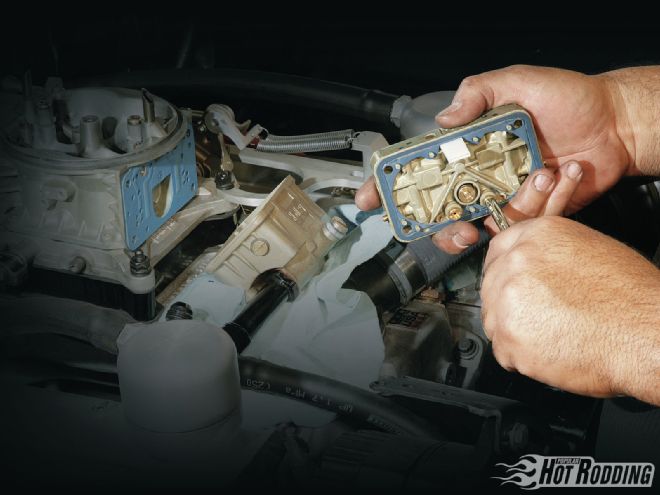

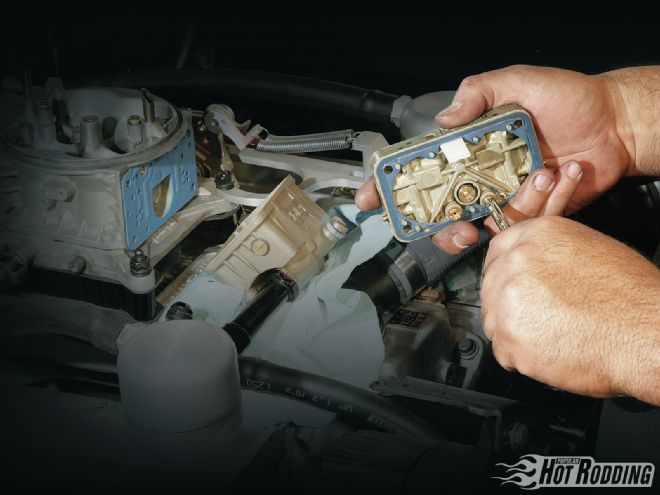

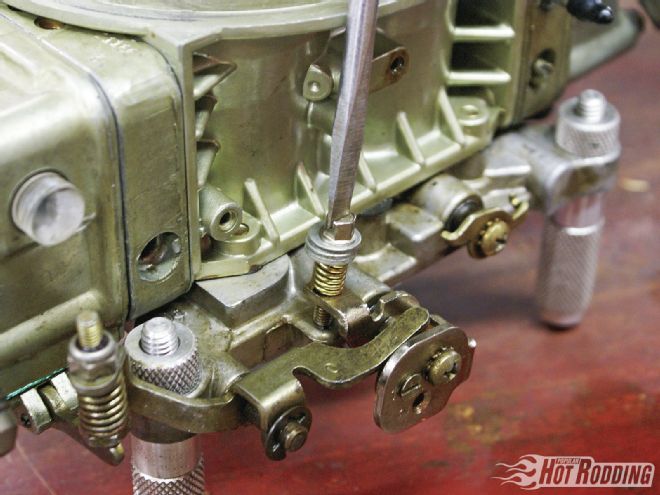

Number 10: Setting The Idle Wrong

Both major carburetor types are designed with idle mixture screws to set the fuel flow at idle. For the most part, these are right on the money. Once again, when running a big camshaft or some combination that is anything but normal, sometimes the idle speed and idle mixture need to be adjusted. For example, on a 4150-style carb, if the engine needs the idle speed screw adjusted more than about a turn, the rectangular transition slot will be exposed to the point where the main jets are providing the fuel and the idle mixture screws (exiting the round hole) won’t react to changes. You can verify the idle speed adjustment by this simple test: If you can screw the idle mixture screws all the way in and the engine keeps running, the transition slot is overexposed. The easy cure for this is to remove the carb and flip it upside down (after draining the fuel) and opening the secondaries slightly via the small Allen head set screw on the underside of the baseplate. Reinstall the carb and go through the normal idle setting procedure again.