When you get right down to it, many of the tasks involved in building a race engine are mundane. It isn’t too difficult to drop a piston in a hole or bolt up an intake manifold. And neither is checking your valve lash or fitting your main and rod bearings. The trick is knowing how to do it right, taking your time to pay attention to the details and having the proper tools which can make your life a lot easier.

Properly fitted main and rod bearings can be the difference between a healthy engine that runs hard and one that throws a bearing and puts you out of a race at the worst possible time.

Properly fitted main and rod bearings can be the difference between a healthy engine that runs hard and one that throws a bearing and puts you out of a race at the worst possible time.

This month we’re going to take an in-depth look at how to measure for the correct clearances between your crank and rod journals, their corresponding bearings and how to install them.

One of the most important factors when it comes to the health and durability of your rotating assembly (crank, rods, and pistons) and the block itself is the amount of open space between the main and rod journals on your crankshaft and the bearing shells they are spinning within. This space is known as the bearing clearance, and it’s critical because that open area is filled with oil which provides a cushion between the journal itself and the bearing. When everything in the engine is right, the oil keeps the steel of the crank journals and the babbit of the bearings separated, and they never touch.

But problems can enter the picture pretty quickly when the bearing clearances aren’t correct. Too little clearance and you’ll have trouble keeping your oil temperatures in check, and a spun bearing is much more likely. On the other hand, if the tolerance is too loose you hemorrhage oil out from around all the bearings. Obviously, too loose is better than too tight, but hitting the center of the bullseye is always preferable.

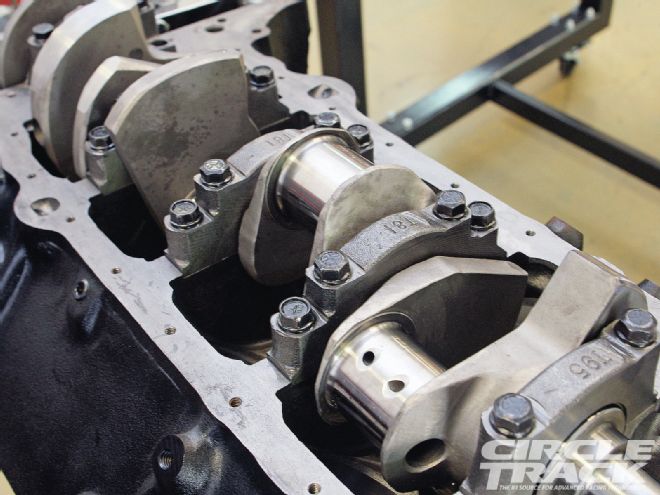

This is a rebuild of the Circle Track dyno mule that we’re upgrading for future testing. Both the rod and main bearings are supplied by King Engine Bearings. We chose its XP performance bearing line because they’re designed to withstand high-load endurance applications—in other words, stock car racing. The first step is to make sure that both the housing bores and both sides of the bearings are clean and grit-free. Fit the bearings into the block so that the tangs on the backsides of the bearings fit into the slots in the block. The grooved bearing shells fit into the housing bore half in the block, while the smooth shells fit into the caps.

This is a rebuild of the Circle Track dyno mule that we’re upgrading for future testing. Both the rod and main bearings are supplied by King Engine Bearings. We chose its XP performance bearing line because they’re designed to withstand high-load endurance applications—in other words, stock car racing. The first step is to make sure that both the housing bores and both sides of the bearings are clean and grit-free. Fit the bearings into the block so that the tangs on the backsides of the bearings fit into the slots in the block. The grooved bearing shells fit into the housing bore half in the block, while the smooth shells fit into the caps.

As a general rule for a race engine, you want to have approximately 0.001-inch of bearing clearance for every inch of journal diameter. So for a 2.100-inch rod journal, it’s always a good idea to shoot for 0.0021 or 0.0022 bearing clearance. And once again, because too little bearing clearance can mean a spun bearing, we always aim to wind up too high rather than too low.

Adjusting the clearance is easy, but probably a bit more expensive than most of us would prefer. Most quality bearing manufacturers make three versions for all the popular styles. First, there’s the standard bearing. This is where you start. If you find you need more clearance, you can purchase an undersized bearing. This means the bearing shell is thinner, which creates 0.001 more clearance than a standard bearing. An oversized bearing is the opposite. It’s thicker and takes away 0.001 of clearance.

One one-thousandth of an inch is a big jump, but you can actually make adjustments in 0.0005 increments—that’s one-half of one thousandths of an inch. To do this you mix half the shell of a one-over or one-under bearing with half the shell from the standard bearing. This means you may have to purchase a couple sets of bearings to get everything just right in your race engine, but sometimes that’s the price you have to pay. Just remember when mixing shells to always keep the sizes in the same alignment. In other words, if you’re using one-unders with standards for your main bearings, put all the one-unders in the cap with the standards in the block side of the housing bore, or vice versa. So with that said, let’s get on with it.