Back when smog control devices first started to appear on cars and light trucks the consensus in the enthusiast community was that performance vehicles were going to be targeted. By the mid-'70s Big Brother had them zeroed in with his nose up our tailpipes and it appeared that any engine that made decent horsepower was going to be gone for good. But then an amazing thing happened-computers came into our lives. Thanks to one or more black boxes, miles of wires, and a host of electronic gizmos, performance engines rebounded-today they run better than ever, get great gas mileage, and they meet stringent emissions standards.

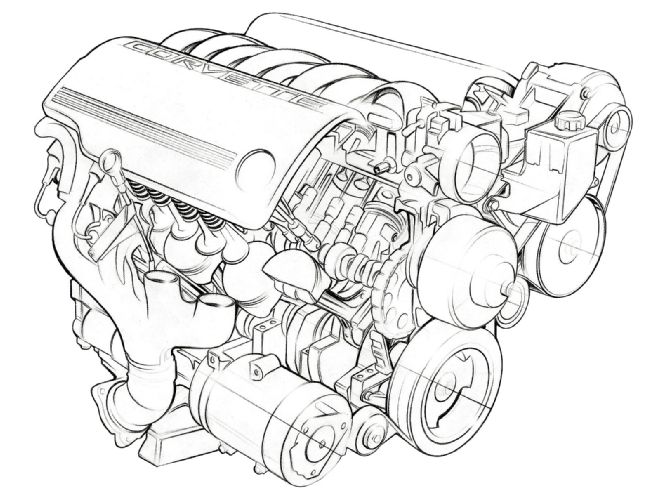

The successor to the throne-arguably the most significant new engine from GM since the introduction of the 265 in 1955. We're just beginning to see the potential of the LS series.

The successor to the throne-arguably the most significant new engine from GM since the introduction of the 265 in 1955. We're just beginning to see the potential of the LS series.

So, what does all this have to do with Custom Classic Truck aficionados? In many cases the rides we know and love fly under the radar in terms of emissions regulations, but then the operative word is "many," as in not all. California has drawn a line in the sand, basically it has been decreed that the year of the engine is the determining factor as far as smog equipment is concerned, no ifs, ands, or buts. So, it you transplant an '02 engine into a '75 truck, the later smog requirements are applicable-many states look at engine swaps the same way. Of course, if an annual inspection isn't required an engine swap may go undetected (although that doesn't make it legal), and in some states that do require inspections, a late-model engine that appears to be from the same family as an earlier, emissions exempt version the swap will be deemed acceptable. Of course there are those states that have street rod laws that exempt 1948 and earlier vehicles from all of this administrivia, but that doesn't do much for owners of '49 and later cars and trucks that want an engine update, particularly those who live in California.

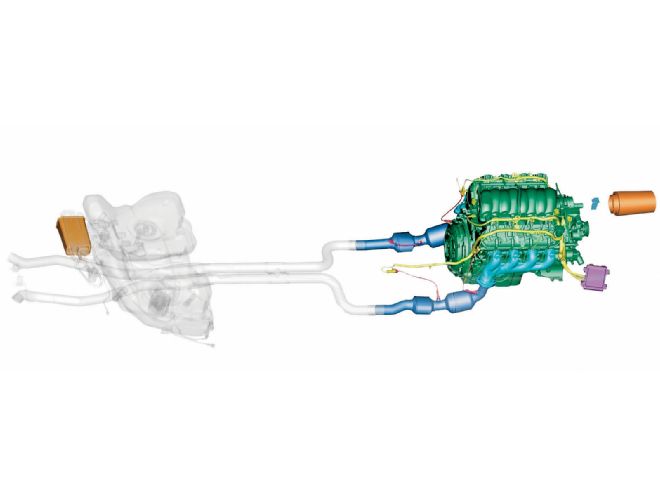

While engine swaps can be problematic, building a truck from the ground up, doing a chassis or cab swap, or any other process that causes you to haul your hauler to the Department of Motor Vehicles in California for a VIN verification or an inspection can derail the registration process if smog compliance is an issue. But there is hope on the horizon for those who want the latest in engine technology under the hood and the least hassle with bureaucratic red tape to obtain the state's blessing in the form of a pair of license plates, it's called the E-ROD system from General Motors. On the verge of being approved by the California Air Resources Board (CARB) this new engine package is based on an LS3 engine and includes the system components that will make any vehicle smog legal in the Golden State as well as those that follow CARB's lead once final approval is granted (hopefully by the time you read this).

GM introduced the E-ROD program at last year's SEMA shindig according to Dr. Jamie Meyer, product marketing manager for GM Performance Parts. "We developed this system because it's the right thing to do, but our engineers did not sacrifice the performance that stirs hot rodders in the first place. It is a compromise-free package that delivers great power and efficiency, with the emissions of a modern vehicle."

GM Performance Parts offers LS series crate engines in a variety of configurations, but the new E-ROD system is certainly a groundbreaker. A 6.2-liter LS3 rated at 430 horsepower and 424 lb-ft of torque is part of the package.

GM Performance Parts offers LS series crate engines in a variety of configurations, but the new E-ROD system is certainly a groundbreaker. A 6.2-liter LS3 rated at 430 horsepower and 424 lb-ft of torque is part of the package.

The E-ROD Package Includes:

6.2-liter LS3 crate engine, rated at 430 horsepower and 424 lb-ft of torque. This is the same base engine found in the Camaro SS and Corvette. (Additional engine choices including the LS7 and LSA are being planned.)

GMPP LS3 engine wiring harness

GMPP engine control module

Exhaust manifolds

Catalytic converters

Oxygen sensors and sensor bosses

Fuel tank evaporative emissions canister

Mass airflow sensor and sensor boss

Accelerator pedal (for use with the LS3's electronic throttle)

Air filter

Instruction manual

Additional Items Required (not included in the kit):

Fuel tank

Fuel lines (including return)

Fuel pump

Purge line from canister to engine purge solenoid

Induction system to incorporate the mass airflow sensor

Exhaust system behind the catalytic converters

Suitable front drive system

The Sources of the Pollution Problem

The basic problem with the internal combustion engine is that it emits a number of pollutants in the process of producing power, such as:

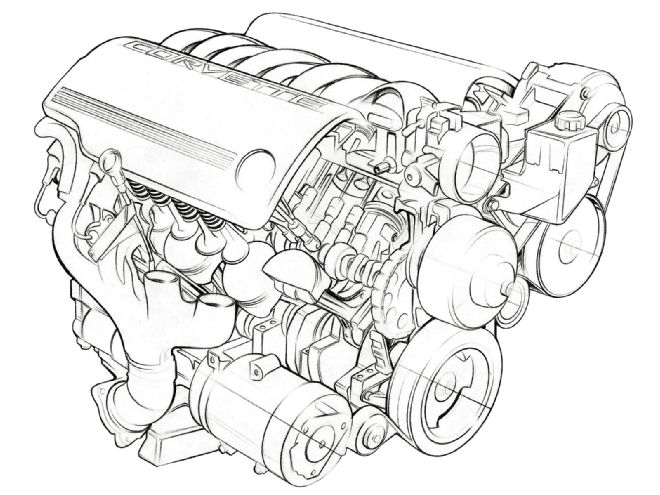

Also included in the E-ROD package is a wiring harness, ECM, catalytic converters, exhaust manifolds, oxygen sensor, evaporative canister, air filter, MAF sensor, and an electronic throttle.

Also included in the E-ROD package is a wiring harness, ECM, catalytic converters, exhaust manifolds, oxygen sensor, evaporative canister, air filter, MAF sensor, and an electronic throttle.

Hydrocarbons-these emissions result when the engine does not burn all the gasoline taken in. Hydrocarbons react in the presence of nitrogen oxides and sunlight to form ground-level ozone, a major component of visible smog.

Nitrogen Oxides (NOx)-created by high-temperature combustion, nitrogen and oxygen atoms form NOx. Like hydrocarbons, they contribute to ozone and the formation of acid rain.

Carbon Monoxide (CO)-a product of incomplete combustion and occurs when carbon in the fuel is partially oxidized rather than converted to carbon dioxide (CO2).

Carbon Dioxide-in recent years, the U.S. Environmental Protection Agency (EPA) has started to view carbon dioxide, a product of "perfect" combustion, as a pollution concern. Carbon dioxide does not directly impair human health, but has been labeled as a "greenhouse gas."

Evaporative Emissions-Hydrocarbons also escape into the air through fuel evaporation from a variety of sources including the fuel tank and carburetor as well as during refueling.

The Cures

When smog control devices first appeared most performance enthusiasts became convinced the end of life as we knew it was near. Although catalytic converters were touted to significantly reduce hydrocarbon and carbon monoxide emissions, they were restrictive-on some engines the effect on performance was like hammering the tailpipe closed. To add to the problem, with the unleaded gas catalytic converters required, the lifespan of exhaust valves became shorter and it appeared the naysayers were right. However, technology eventually came to the rescue once again. Manufacturers stepped up and began using better materials for valves and seats and consumers began to notice that parts like spark plugs and exhaust systems lasted longer without lead in the fuel. Maybe things weren't so grim after all.

By 1980 more sophisticated emission control systems came along including the "three-way" catalytic converter, which turned carbon monoxide and hydrocarbons to carbon dioxide and water and also helped reduce nitrogen oxides to elemental nitrogen and oxygen. And to top it off, these new converters didn't restrict flow like the earlier versions, so many performance vehicles had that beloved rumble out of the exhaust pipes once more. But the big reason emissions systems have become more effective and we have better performing powerplants in terms of horsepower, mileage, and longevity is directly attributable to the sophistication of today's computer controlled engine management systems. Let's face it, nothing looks cooler than a small-block with a handful of carburetors and a magneto, but nothing runs better than a new LS series engine with computer controlled fuel injection and electronic ignition.

Once the final stamp of approval is granted by the California Air Resources Board, the E-ROD package will meet emissions standards and be legal in the Golden State and all others that follow its lead.

Once the final stamp of approval is granted by the California Air Resources Board, the E-ROD package will meet emissions standards and be legal in the Golden State and all others that follow its lead.

A contemporary automotive Electronic Control Module (ECM) makes continuous changes to the engine's state of tune with information from a variety of sensors such as:

Mass Airflow (MAF) Sensors-measures the volume and density of air entering the engine. The computer uses this information in conjunction with input from other sensors to calculate the correct amount of fuel to deliver to the engine, as well as ignition timing.

RPM/Crank/Cam Position Sensors-used to control ignition timing.

Manifold Absolute Pressure (MAP)-for altitude compensation and load correction.

Coolant Sensor (CTS)-monitors operating temperature for fuel/spark adjustments.

Manifold Air Temperature (MAT)-monitors intake air temperature.

Throttle Position Sensor (TPS)-feedback for fuel control.

Knock Sensor-detects and protects the engine from detonation and adapts the system to octane levels.

Pre-Catalyst Oxygen Sensors-controls A/F ratio.

Post-Catalyst Oxygen Sensors-performs catalyst diagnostics.

With all the data available from the sensors, and the ability of the computer to make the necessary adjustments in the blink of an eye, electronic engine management systems are what make clean-running engines that crank out 430 horsepower possible.

There are a variety of engines in the LS series, but all have the characteristic features. Note the tall intake ports, separate valley cover and the round mount in the pan to accept the oil filter.

There are a variety of engines in the LS series, but all have the characteristic features. Note the tall intake ports, separate valley cover and the round mount in the pan to accept the oil filter.

Throttle By Wire

The LS1 is the first passenger car engine from General Motors equipped with electronic throttle control and a version of that is used in the E-ROD system. Throttle by wire has three main components: a sensor on the throttle pedal, an electronic activator on the throttle body; and of course a control module that may or may not be part of the engine management system.

While throttle by wire seems complicated it does make it easier for engineers to incorporate other features such as cruise and traction control.

Evaporative Emissions Control

Since 1971 (1970 in California), all U.S. vehicles have had fuel systems that do not vent directly to the atmosphere. Fuel tanks and carburetors (on cars so equipped) have vent lines that connect to a canister containing activated carbon where any vapors released are trapped. When the engine starts any vapor that has accumulated is drawn into the engine and burned. When the engine is running, fresh air is drawn into the fuel tank to replace the fuel consumed.

The Future of the Hobby

At one time, building a smog-legal, modified truck was the furthest thing from most of our minds, but then who would have guessed we'd be building reproduction versions of some of our favorite designs on a brand-new chassis? It could be that the E-ROD system will be what it takes to get a new/old truck going down the road with the blessings of your state's DMV. It may also be the most effective way to meet emissions standards when swapping engines in trucks that have to get a yearly stamp of approval from the smog cops. Then again, this just may be the best way yet to have the latest in butt-kickin' horsepower that's reliable, gets great gas mileage, and is good for the environment to boot.

LS blocks are a deep skirt design that allows for cross-bolted main caps. In addition, the cast oil pans reinforce the bottom end.

LS blocks are a deep skirt design that allows for cross-bolted main caps. In addition, the cast oil pans reinforce the bottom end.

The Alphabet Soup of LS Engines

General Motors' LS engines can be broken down into two series: Generation III and Generation IV. They share many of the same features and attributes. Gen III blocks were made from cast iron in 4.8L, 5.3L, and 6.0L sizes (used primarily in trucks) and aluminum for 5.3L, 5.7L, and 6.0L. Gen IVs are basically the big-bore versions of the LS series and were designed to accept GM's "displacement on demand," or DOD, technology.

The first engine in the Gen III series was the LS1, which featured a bore of 3.897 inches and a stroke of 3.662 inches, resulting in a displacement of 345.69 cubic inches, however, Chevrolet called it a 350, or a 5.7L engine. Based on an aluminum block that weighed a mere 107 pounds, thanks to the deep skirt design and six-bolt main caps, it was every bit as rigid as its 160-pound cast-iron predecessor. Also found inside the block were cast-iron liners; a new, shorter nodular iron crankshaft; and powdered metal rods, the strongest to find their way inside a production GM engine.

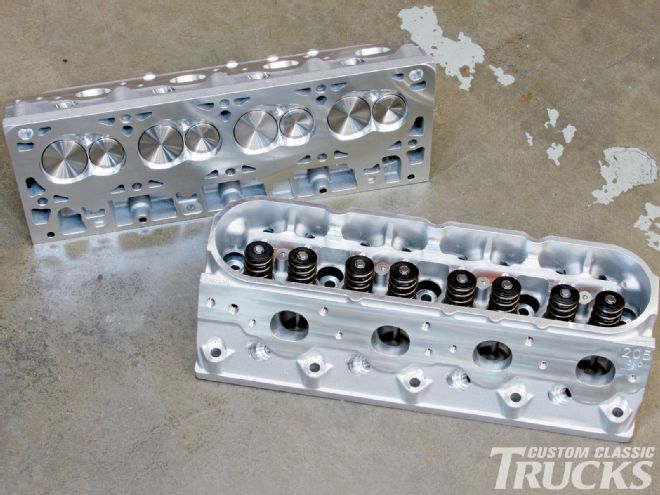

The architecture of the LS1 block is considerably different to those familiar with the traditional small-block Chevy, there are significant differences in the heads as well. One of the most obvious is that all the intake ports are identical, as are the exhausts, which simply means that all cylinders breathe equally well. Less obvious differences in the new heads are the valve angles. It's generally agreed that the shallower the valve angles the better. The LS1 valves are at a 15-degree angle, considerably less than the earlier small-block's 23 degrees. But one of the LS head's most important attributes is the location of the fuel injectors. As these heads were designed for fuel injection rather than retrofit with it, the injector's fuel streams are aimed directly at the back of the intake valves.

Like most contemporary engines, the LS1 uses roller lifters as well as investment cast roller rockers, but one of the most unique pieces is a manifold from composite material that allows for the curved runner configuration while being light and cost effective. Another new feature found on the manifold is the fly-by-wire throttle body. The LS1 was the first GM engine in cars to use a computer-controlled throttle (light-duty diesel trucks began using them in '95).

The new heads are unique, the valves have been reoriented so the center exhaust ports are no longer adjacent and the new ports give the fuel injectors a direct shot at the intake valves.

The new heads are unique, the valves have been reoriented so the center exhaust ports are no longer adjacent and the new ports give the fuel injectors a direct shot at the intake valves.

Of all the features of the LS1 that are out of the ordinary, the most obvious are the rocker cover-mounted coil assemblies. Each cylinder has its own coil and coil driver assembly with a short secondary wire connecting to each spark plug. The reasons given for moving the coils to the covers is that the shorter plug wires lost less energy so more is delivered to the plug, as well as reduced radio frequency interference with on-board computers. A less noticeable feature of the ignition system is the change in firing order; no longer using the familiar 1-8-4-3-6-5-7-2 sequence, new engines fire 1-8-7-2-6-5-4-3.

With all that is unique on the LS1, one of the pieces that almost escapes notice is the pan-but there's more to it than meets the eye. There have been a half-dozen or more cast-aluminum pans used on these engines: the Corvette, or batwing pan, is a two-piece and has two wings to the sides, and the Camaro and Firebird pans have a shallow rear sump. But no matter what the shape is, in all cases the pan becomes a part of the engine's structure when screwed in place and contributes to the block's rigidity. An unusual feature is these pans also provide a mount for the oil filter.

Crate Motor Offerings

Currently, General Motors Performance Parts offers a variety of LS engines-they include:

LS327/327 GMPP describes the 5.3L as having the same 327-cubic-inch displacement of the small-blocks from the '60s but in a new LS package. It's been equipped with a hotter than stock cam and Grafal-coated high-silicon pistons.

LS1

The first and most popular version of the series-the LS1 features a deep skirt, six-bolt main block, with structural oil pan, a high-lift camshaft actuating big 2.00/1.55-inch valves in symmetrical-port cylinder heads. Rated at 350 horsepower and 365 lb-ft of torque it comes with a GTO-style oil pan, electronic drive-by-wire throttle body, intake manifold, exhaust manifolds, fuel rail with injectors, balancer, and 14-inch automatic transmission flexplate.

LS6

Producing more than 400 horsepower, the LS6 has been equipped with hollow-stem valves, a more aggressive camshaft, improved intake and higher-rate valvesprings along with higher-compression pistons to raise horsepower to 405, and torque to 400 lb-ft. It comes with a CTS-V oil pan, large-volume composite intake manifold with single-bore throttle body, and high-performance long-style exhaust manifolds.

LS3

This 6.2-liter engine produces 430 horsepower and 424 lb-ft of torque thanks to revised cylinder heads featuring rectangle ports, 63cc combustion chambers, 2.16-inch intake valves, and 1.59-inch exhaust valves. The camshaft has 0.551-inches of lift on the intake side with less overlap (than the LS2) and 1.7:1 ratio rocker arms are used. The aluminum six-bolt main block features 4.06-inch bores and 3.62-inch stroke, a nodular iron crankshaft, powdered metal rods, and aluminum pistons with a compression ratio of 10.7:1.

LS 376/480

An LS3 with an upgraded camshaft (PN 12617570) with 0.525-inch intake and exhaust valve lift. The duration is 219 degrees intake and 228 degrees exhaust (at 0.050-inch lift). Said to idle and cruise just like an LS3, this cam is good for 50 horsepower.

LS 376/515

An upgraded LS3 that is equipped with an aggressive camshaft and GM Performance Part's exclusive carbureted intake manifold produces 515 horsepower. The hydraulic roller camshaft has 0.525-inch intake and exhaust valve lift with duration of 226 degrees on the intake and 236 on the exhaust.

LS7

Using a 7.0-liter aluminum dry-sump block, CNC-ported cylinder heads, and titanium rods and valves this engine pumps out 505 hp and 470 lb-ft of torque. As an example of its efficiency, the LS7 helps the '06 ZO6 get over 28 mpg while still being the fastest Corvette ever produced.

LSA

Based on the LS9, the LSA uses a unique aluminum-cylinder block casting that houses a forged steel crankshaft, integrated piston cooling oil jets, high-flow cylinder heads, and relatively mild camshaft to produce 556 horsepower and 551 lb-ft of torque. It has a slightly smaller supercharger than the LS9 and comes with a conventional wet-sump lubrication system.

LS9

Long rumored to be everything from the powerplant for the new Corvette Stingray and/or Camaro to a truck engine, the supercharged LS9 is now available in crate form. While it shares the 6.2L displacement of other LS engines, the LS9 features a stronger block casting, stronger cylinder head castings, and steel cylinder liners that are honed with a deck plate installed to maximize performance and cylinder sealing. Coupled with a Roots-style supercharger, this engine in the ZR1 Corvette produces 638 horsepower and 604 lb-ft torque.