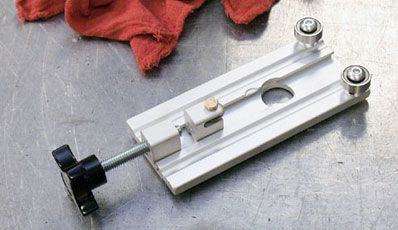

An oil-filter cutter, such as this one from Powerhouse Products, is a great tool to help you read an oil-filter element to get clues to your race engine's health.

An oil-filter cutter, such as this one from Powerhouse Products, is a great tool to help you read an oil-filter element to get clues to your race engine's health.

After every race or two, you probably have a list of items to check on your race car. Most likely, you check your brake pads for excessive wear and the rotors for cracks. You may check your suspension components for damage and your ball joints and tie-rod ends for slop and signs of wear.

But what about your engine? If you wait until your driver tells you that something doesn't "feel right" from the driver's seat, it may already be too late. Stock car racing engines do not have onboard diagnostic systems like modern over-the-road vehicles, but that doesn't mean that you can't get clues about your engine's health without tearing it down. Savvy racers and engine builders will frequently look at the spark plugs and occasionally perform a leakdown check on a race engine, which can tell you a lot. But there is another check you can easily perform that will help you determine your engine's health. Hopefully, it will help you catch a developing issue before it becomes a full-blown (and expensive) problem.

This is a wire-screen filter from an engine dyno, and it's easy to see how much "stuff" floats through the oiling system on a new engine build. This is the accumulation after KT Engine Development ran two new race engines on its dyno. (The screen is usually cleaned after every dyno session, but it wasn't cleaned this time so that the buildup would be easier to see.) Much of what you see here is lint from cleaning rags and other harmless matter. The amount of material that gets trapped in a filter should dwindle to virtually nothing in a healthy engine after the break-in process is complete.

This is a wire-screen filter from an engine dyno, and it's easy to see how much "stuff" floats through the oiling system on a new engine build. This is the accumulation after KT Engine Development ran two new race engines on its dyno. (The screen is usually cleaned after every dyno session, but it wasn't cleaned this time so that the buildup would be easier to see.) Much of what you see here is lint from cleaning rags and other harmless matter. The amount of material that gets trapped in a filter should dwindle to virtually nothing in a healthy engine after the break-in process is complete.

It's definitely messy, but inspecting the particles your oil filter has trapped can be a valuable diagnostic tool for the smart racer or crew chief. Race teams running a dry-sump oiling system have been doing this for years, and the external oil tank makes it easy to install a wire screen filter to simplify and expedite the process. For racers in lower classes, where the more common wet-sump oiling systems are mandated, reading the oil filter is a little more difficult; but it certainly is no less useful. This is because the oiling system in any automobile engine not only provides lubrication, but also picks up any trash, contaminants, or shredded race parts. If small enough, any metal that has been shaved off of a component, or even chunks from a broken component, will eventually find its way to the oil filter if it doesn't become embedded in the bearing babbit. Inspecting the "stuff" that gets trapped in your oil filter element can give you a very accurate idea of what components, if any, are failing inside your engine.

Cut 'Em Up Almost all wet-sump race cars use a modern canister-style oil filter. This is true whether you have a remote filter mount or the filter attaches directly to the engine block. The biggest problem with inspecting the filter element inside a canister filter is simply getting the thing open. The canister-style filter is encased in stamped metal, which is quite durable, in order to prevent leaks. When attempting to get to the filter element, it can be tempting to simply go at the metal canister with a pair of tin snips. You should avoid this urge because while you will eventually succeed, you are assured to make a tremendous mess, and the likelihood of getting a nasty cut (complete with motor oil in the wound) is high.

KT Engine's Nathan Allmond places a canister-style filter into the cutter. Regardless of how much oil you've already drained from the canister, you'll still make a mess when cutting open a filter.

KT Engine's Nathan Allmond places a canister-style filter into the cutter. Regardless of how much oil you've already drained from the canister, you'll still make a mess when cutting open a filter.

A few companies, such as Powerhouse Products, produce cutters designed specifically to open a canister-style oil filter as painlessly as possible. While there is no way to make opening your old filter completely mess free, a purpose-built cutter is definitely faster, safer, simpler, and less messy.

With a new race motor, you should definitely inspect your filter media after break-in and after the first race or two. But once an engine is broken-in and showing no signs of trouble, this isn't necessary. You can safely back off on the frequency and only inspect your filter media at the same intervals you change your oil filter. After all, filters are too expensive to be cut up unnecessarily.

Spin the cutting tool around the filter, occasionally tightening the cutter as you go. The cutter will continually deepen the groove until it eventually breaks through the metal casing.

Spin the cutting tool around the filter, occasionally tightening the cutter as you go. The cutter will continually deepen the groove until it eventually breaks through the metal casing.

Reading the Filter Once the filter media is free from the canister, you can take a moment to clean up any spilled oil before beginning your inspection. The trapped material in your filter media can tell you a lot about what's going on inside your engine, but first you have to be able to determine exactly what you are looking at.

Begin by tapping the filter element on a table to see if larger chunks of debris fall out, which could signal a serious problem. It is difficult to see smaller shavings of metal, which is what you will typically find when you have a problem, in the oil-soaked filter media. It's best to spread out the filter and look into the bottom of the folds.

What you are likely to find depends a lot on the state of the engine. After breaking it in, it's normal to see a small amount of material of all types in the filter media. But you should see far less in a healthy engine that has been running for a while.

Once the cut is all the way through, you can pull the lid off and remove the filter element.

Once the cut is all the way through, you can pull the lid off and remove the filter element.

One of the most difficult aspects of reading an oil filter is determining exactly what you've found. You can use a small magnet and run it across the filter to pick up any steel shavings. This separates any steel, which can be piston rings, parts of the cylinder wall, or any other number of things, from the non-magnetic metals left behind. What's left is most likely aluminum from the pistons or cylinder heads. Non-magnetic material can also be titanium, if you are running titanium valves or spring retainers. Another easy test to determine whether you are looking at aluminum or steel shavings in your filter is to rub it between your fingers. Aluminum is shiny and bends when you mash it between your fingers. Steel is less shiny and more likely to break when pressed between your fingers. Titanium is shiny, like aluminum, but breaks like steel instead of bending like aluminum.

The best place to inspect the filter element for trapped particles is in the bottom of the folds.

The best place to inspect the filter element for trapped particles is in the bottom of the folds.

Anytime you inspect your filter and find a lot of steel, it is cause for concern and potentially requires a teardown. Normal wear creates a small amount of steel shavings, especially in a new engine. This can come from the rings seating or the ridges in the cylinder bores' crosshatch being worn down. However, if you suddenly notice a lot of steel filings in your filter, you might be losing a camshaft, especially if you are running a flat-tappet cam with a very aggressive lobe design. You can also rub a bit of the motor oil between your fingers; if it feels gritty, that's another sign that you have a lot of metal shavings or other contaminants being picked up by the oiling system.

Aluminum flakes are less of a concern and usually originate from the piston skirt wearing against the cylinder wall. OEM-style aluminum bearings can also be a source. Most engine builders still prefer softer babbit bearings with a copper backing. This makes a bearing problem easier to spot because a disintegrating bearing will leave copper-colored filings in the filter media.

An easy way to check for metal filings is to run a small magnet through the bottom of the filter media folds as well as through any remaining oil in the bottom of the canister casing.

An easy way to check for metal filings is to run a small magnet through the bottom of the filter media folds as well as through any remaining oil in the bottom of the canister casing.

Finally, it is critical to clean your engine as well as possible before final assembly. This is a good engine-building practice that ensures anything picked up in the filter media isn't simply a leftover from before the build. After running a new build, the filter will almost always have lint from cleaning towels and small chunks of silicone, which is not a concern but should be minimized as much as possible. A greater problem stems from not properly cleaning the oil galleries on a rebuild. If a bunch of metal and rust gets flushed into the filter, you have no idea whether you are looking at remnants from a poor cleaning job or signs of a new problem, so check it carefully. Read your filter, save your motor!