A year ago, when we dropped an LS7 into the HOT ROD Solstice, that crate engine was relatively new, and there weren't very many in the hungry hands of the public. But in the time since, GM Performance Parts has sold a bunch of the LS7 crate engines-pretty impressive considering the fairly high street price that hovers around $13,000 (though the list price is $17,000). But the engine (PN 17802397 at your local GMPP dealer) is worth it.

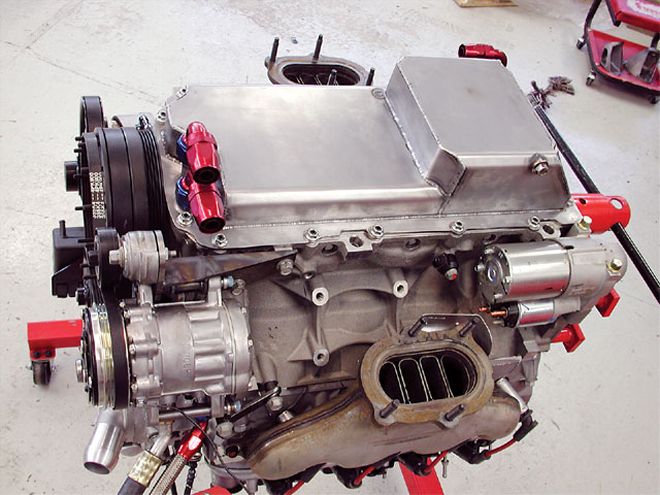

The LS7's parts list reads like a high-end endurance racing engine, with titanium rods and intake valves, CNC-ported heads, offset rockers, and a dry-sump oiling system. With 427 ci and 505 hp out of the box, this is one heck of a package. And as you may have seen in our exclusive dyno test in the Feb. '06 issue, a cam-and-header swap makes it an easy 580hp engine-600 if you want to lean on it. And that's with OE-spec durability. Wow.

As fun as the Solstice project was, we wanted to see what was involved in dropping the engine into a car more representative of the readers of HOT ROD. And what car is more common than a first-gen Camaro? It just so happened that GM Performance Division Engineer Mark Stielow was doing just this swap on his own time: sticking a box-stock LS7 crate motor in his latest Camaro project, a '69 code-named Camaro X. Stielow is known for building first-gen Camaros with wild engines using either oddball cylinder heads or multiple turbochargers, but that was before the LS7 debuted, and now it's a no-brainer for his car. Stielow says, "The goal for Camaro X was to build a fast car, but one that has the driveability and performance of a Z06 Corvette."

Of course, the external architecture of the Gen I (traditional small-block) and Gen III/IV (LS-series) engines is completely different, so it didn't look to be a drop-in engine swap. But thanks to a few parts from American Touring Specialties (ATS), it turned out to be just that. ATS supplied the motor mounts, headers, an oil pan, and a transmission crossmember to allow an F-body T56 six-speed to fit. The company also supplied a hydraulic clutch slave cylinder mount. The engine mounts, oil pan, and transmission mounts made the engine and transmission a bolt-in deal, and the only hole that needed to be cut was for the shifter to come through the floor. The next potential problem area was the dry-sump system, with its plumbing and remote oil tank. Stielow used a Peterson 2-gallon tank and mounted it where the battery used to be.

The other key enabler to get the dry-sump LS7 into a stock early Camaro is this trick oil pan made by ATS. The pan ($499) is made of steel, is redesigned to clear the subframe, and has inlets and an outlet for the dry-sump system.

The other key enabler to get the dry-sump LS7 into a stock early Camaro is this trick oil pan made by ATS. The pan ($499) is made of steel, is redesigned to clear the subframe, and has inlets and an outlet for the dry-sump system.

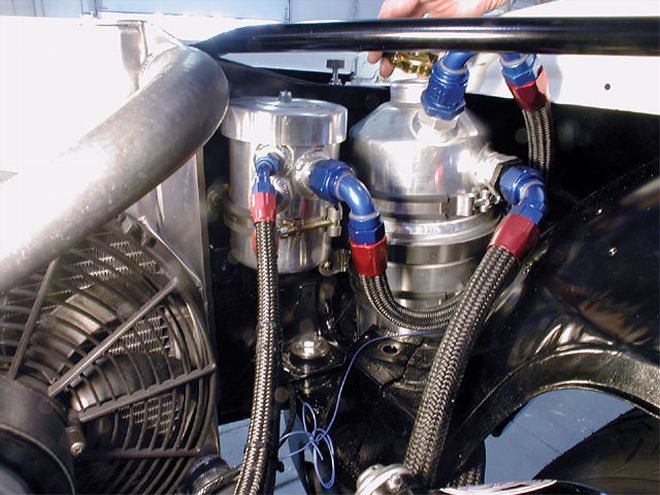

The other parts of the dry-sump system are the tank (right) and breather (left). The best-fitting oil tank is a Peterson 2-gallon tank (PN 08-0005) with a -12AN pickup, a -12AN return, and a -12AN breather. The oil pump is behind the engine's harmonic damper.

The other parts of the dry-sump system are the tank (right) and breather (left). The best-fitting oil tank is a Peterson 2-gallon tank (PN 08-0005) with a -12AN pickup, a -12AN return, and a -12AN breather. The oil pump is behind the engine's harmonic damper.

With the engine in the car, the next hurdle was figuring out how to make it run-a significant problem considering the LS7's throttle-by-wire arrangement. Adapting a stock wiring harness would be a nightmare, and though GMPD is working on standalone controllers for its line of late-model crate engines (see the sidebar "Controllers to Come"), a unit wasn't available when we were doing this story. Thankfully, MSD has just come out with a killer MEFI4 controller and a mechanical throttle body to allow the engine to work in just about any application. By converting the engine to the MSD EFI system, you no longer need the throttle-by-wire throttle body or the stock mass airflow meter, and MSD's InGenius software allows full control of the system's calibrations. The system comes with an engine calibration that will start and run the engine, but for the best performance (especially if you've thrown in a different cam and/or added headers), you should fine-tune it to the application.

The fuel system consists of a bolt-in stainless fuel tank from Rick's Hot Rod Shop and an in-tank Walbro pump. The LS7 uses a returnless fuel system, so the stock Corvette regulator (PN 10299146) is mounted back by the tank and sends 58 psi of fuel pressure to the stock LS7 injectors. The last thing to button up was the exhaust system, which consists of ATS's stainless steel tri-Y headers and a Stainless Works 3-inch exhaust system, installed by Stenod Performance.

So how does it run? Well, it's wintertime in Detroit (where the car is) as we write this, so Stielow doesn't have any numbers on it yet. But, he says, "Based on the power and weight compared to my other cars, it should run 11.90s at about 120 mph." As with every Stielow-built car, that performance should come on stiff, road-racey suspension and low-profile tires. You could certainly build an 11-second car much cheaper with a traditional small-block and a carburetor, but you'd be hard pressed to match the driveability, mileage, and durability of the LS7 crate engine.

Controllers To Come

When this engine swap was happening, GM Performance Parts didn't have an EFI controller for the LS-series crate engines, but it does now. PN 19166567 is a new GMPP plug-and-play controller for the LS7 (PN 19166568 for the LS2). Unlike the MSD controllers, these are nonprogrammable units, meaning they come with the factory tune for the production engine. GMPP is looking into releasing programmable units for the entire LS crate-engine family, but the company doesn't have them yet. For more information on the GMPP controller, check out page 298 of the current 2007 catalog or log on to www.gmperformanceparts.com.

Rick's Hot Rod Shop in El Paso, Texas, built a stainless steel fuel tank with an internal Walbro pump from Kinsler. It bolts directly in place of the stock tank and includes fuel-feed and return lines and a fuel-level sensor. The fuel filter and regulator are a stock GM part from a Corvette (PN 10299146).

Rick's Hot Rod Shop in El Paso, Texas, built a stainless steel fuel tank with an internal Walbro pump from Kinsler. It bolts directly in place of the stock tank and includes fuel-feed and return lines and a fuel-level sensor. The fuel filter and regulator are a stock GM part from a Corvette (PN 10299146).

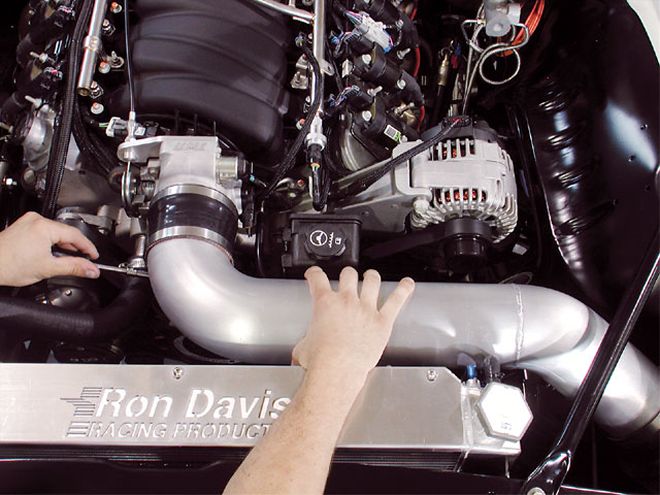

Ron Davis makes a nice bolt-in radiator for a first-gen F-body to accommodate an LS-based engine, with the inlet and outlet both on the passenger side to allow room for the induction tube. The inlet tube was made by Stenod Performance out of 4-inch, mandrel-bent aluminum tubing and has a 4-inch K&N filter that pulls air from behind the driver-side headlight.

Ron Davis makes a nice bolt-in radiator for a first-gen F-body to accommodate an LS-based engine, with the inlet and outlet both on the passenger side to allow room for the induction tube. The inlet tube was made by Stenod Performance out of 4-inch, mandrel-bent aluminum tubing and has a 4-inch K&N filter that pulls air from behind the driver-side headlight.

Stenod Performance installed the Stainless Works 3-inch exhaust.

Stenod Performance installed the Stainless Works 3-inch exhaust.

Camaro X

The name came about because this is the 10th first-gen Camaro Stielow has built, and this latest one uses the best ideas from three of his previous cars. "I had a chance to drive the Mule, the Thrasher, and then the Red Witch (all previous Stielow Camaros) back-to-back and could really compare the best parts of each car. So I took what I liked best on each car and built it into this one. The four-link rear suspension is the same as the Mule's, the front suspension and steering are the same as Thrasher, that kind of thing," Stielow says. The previous cars were built with the intention of running Car and Driver's grueling One Lap of America event, and while most of Camaro X is built to the same level, it doesn't have the full rollcage the other cars have. "That kind of 'cage makes it hard to fit air conditioning under the dash, and it's harder to get in and out of. The four-point bar in this car is basically a glorified attachment point for the safety harnesses. I wanted a car I could drive around-you know, an old car that drives like a ZO6. And that's what this car is."

The Camaro started life as an all-original California car, which was a nice change from the beaters Stielow had started with on previous projects. It now has the LS7 and T56 drivetrain, of course, with a Currie 9-inch rearend suspended by Stielow's own four-link setup, just like on the Mule Camaro. The front uses Detroit Speed control arms with taller ATS spindles la the Thrasher. The brakes are from Baer, and the 18-inch wheels and tires came from Fikse and Yokohama. Brent Jarvis at Performance Restorations in Mundelein, Illinois, did the body and paint, shooting the car white to mimic Stielow's first Camaro, which was built back in the mid-'90s. The car weighs 3,500 pounds with Stielow in it, and you can see it in person on the '07 HOT ROD Power Tour.