Big-inch small-blocks are all the rage these days. With the mass proliferation of tall-deck aftermarket blocks and dirt cheap stroker cranks, the grunt and cubes that were once the exclusive territory of big-blocks can be had in a tidy, compact package. Play your cards wrong, however, and a big-inch small-block can burn a big-block-size hole in your pocket. The intensive labor and dollars required to balance long-stroke rotating assemblies and clearance blocks and rods means that they're often more about pimp factor than practicality. Nonetheless, these massive small-blocks still have undeniable sex appeal, and there's a very simple way to avoid the aforementioned pitfalls: pass up on a small-block Chevy and build a 351 Ford Windsor instead.

Granted, the small-block Chevy is the king of all performance motors in terms of popularity and parts availability, nevertheless, it's outgunned by the 351 Windsor in several key areas when maximum displacement is the agenda. Most of the Windsor's advantages are attributable to its deck height of 9.500 inches (9.000 inches for the SBC). Thanks to the extra space provided by its longer cylinder bores, a Windsor can easily swallow up a 4.250-inch stroke. The tall deck also positions the camshaft much higher in the block, virtually eliminating interference issues between the cam and the rods. Likewise, the distance between the Windsor's pan rails is significantly wider than a SBC. As a result, the crankcase is much larger, which-in conjunction with the tall deck-can accommodate bigger crank counterweights for easier balancing.

Custom Wiseco pistons feature a 15cc reverse dome and weigh just 425 grams.

Custom Wiseco pistons feature a 15cc reverse dome and weigh just 425 grams.

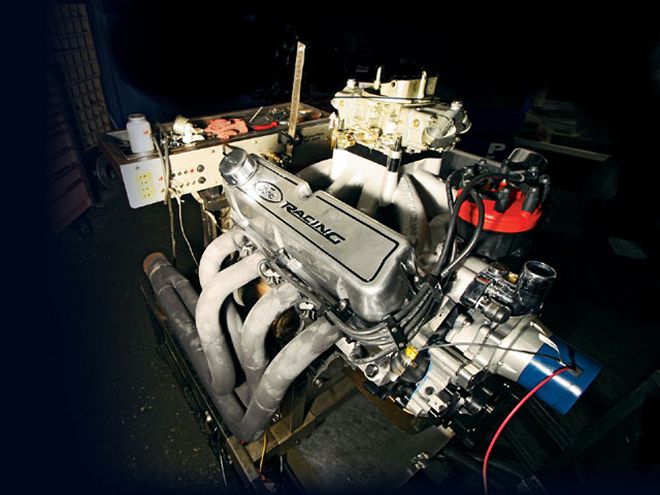

Don't be alarmed, but 351 Windsor production blocks can be built as large as 434 ci and still run reliably. The subject at hand here is a 418ci street/strip mill that produces 670 hp on pump gas, built by HK Enterprises of Houston, Texas. The truly impressive part of this motor is that it's built almost entirely from off-the-shelf parts. Anyone with a Summit catalog can replicate this combination. No top secret head porters or machinists are required. "Even a lot of the Ford guys don't think a Windsor can be built this large, but I'm not sure where that misconception comes from," says Erik Koening of HK Enterprises. "Maybe they think the issues that come up when building a big-inch small-block are universal to all types of small-blocks, but the truth of the matter is there's just much more space inside a 351 Windsor than in a Chevy."

The basis for this 418 is a production 351 Windsor block that's been bored to 4.030 inches and paired with a 4340 forged-steel Eagle 4.100-inch crank. While factory Windsor cranks came externally balanced, the Eagle piece is set up for internal balancing to promote component longevity at high rpm. Combined with a set of 6.200-inch Eagle steel H-beam rods, it results in a reasonable rod-to-stroke ratio of 1.51. Like most aftermarket 351 Windsor rods, they feature a smaller 2.100-inch rod journal diameter as opposed to the factory 2.311-inch journals, which keeps bearing speed in check and allows for the use of SBC rods. Wiseco pistons with a 15cc reverse-dome maintain a 93 octane-friendly 11.5:1 compression ratio.

Despite the long 4.100-in stroke, there's still 1.235-in of compression height. With a more solid aftermarket block, a hit of nitrous is a no-brainer.

Despite the long 4.100-in stroke, there's still 1.235-in of compression height. With a more solid aftermarket block, a hit of nitrous is a no-brainer.

When it came time to button up the short-block, the capacious internal dimensions provided by the 351 Windsor architecture kept prep work to a minimum. Thanks to the favorable cam positioning within the block, the slim-profile Eagle rods clear the cam with room to spare. Although the bottom of the cylinders require a wee bit of grinding to clear the rod bolts, it isn't close to the major surgery required in a Chevy. "You can't even think about plopping in a 4-inch stroke in a Chevy without serious clearancing of the block, and running a small base circle cam is a must," says Erik. "There are no clearance issues whatsoever with the Windsor. In fact, we didn't even have to use a small base circle cam with this motor."

Space issues aside, long-stroke small-blocks are usually a big pain to balance. Pulling the pistons that far down the cylinder bores leaves very little space between the piston skirts and the crank counterweights at bottom dead center. Consequently, many long-stroke cranks have counterweights that are much smaller than ideal. Compensating for this requires adding lots of heavy metal to the counterweights, which makes for a time- and money-consuming balancing process. However, the extra real estate afforded by the Windsor's tall deck and wide pan rails eliminates such headaches. "With the extra room inside these motors, the counterweights are much taller than in a small-block Chevy which makes them much easier to balance," says Erik. "Even with a 4.100- or a 4.250-inch stroke, a Windsor is easier to balance than a Chevy with a 3.750-inch stroke and aluminum rods."

Standard tension Wiseco 1/16-, 1/16-, and 3/16-inch rings provide cylinder seal.

Standard tension Wiseco 1/16-, 1/16-, and 3/16-inch rings provide cylinder seal.

Feeding the bottom end is a set of out-of-the-box AFR 225cc heads with 2.08/1.60-inch valves. They're advertised as flowing 317/255 cfm at .700-inch lift, and from our experience, AFR's numbers are spot-on if not a bit conservative. The heads are mated to an untouched Edelbrock Super Victor intake manifold which sits beneath a 1,000-cfm Holley 4150-series carburetor. Managing the airflow is a mild 260/266-at-0.050 COMP Xtreme Energy solid-roller cam with .666/.677-inch lift and a 110 degree lobe separation angle. COMP lifters, 3/8-inch pushrods, and Probe 1.7:1 shaft-mount rockers comprise the rest of the valvetrain. Although Probe suffers from a mixed reputation amongst the masses, these rockers fit perfectly and didn't require any additional machining.

As promising as the 418 looks on paper, it performed even better in the dyno room. On the School of Automotive Machinists' SuperFlow 902 dyno, it kicked out an impressive 670 hp at 7,300 rpm and 540 lb-ft of torque at 5,600 rpm. Had this motor been fitted with a longer 4.250-inch crank-bumping up displacement to 434 ci-Erik estimates a 3 percent increase in torque across the board. That's not too shabby for a pump gas street/strip motor built with off-the-shelf parts-that doesn't rely on subtle tricks like Hard Blok fill or a vacuum pump. This ain't no dyno queen either. Not long after our dyno session, the 418 powered a 3,000-lb Fox-body Mustang down the quarter-mile in 10.40 seconds at 136 mph. Not bad considering the 95 heat.

Small-block, Chevy-sized piston pins open up the door for using a slew of off-the-shelf SBC rods. This piece weighs 115 grams.

Small-block, Chevy-sized piston pins open up the door for using a slew of off-the-shelf SBC rods. This piece weighs 115 grams.

While the power numbers speak for themselves, the real question is how long can a factory block take this kind of abuse before splitting in half? According to Erik, it will last for quite some time. "In a street/strip application, these Windsors can safely handle 650-675 hp and 7,500 rpm," he says. "People routinely push them to 1,000 hp, but you never know how long they'll last at that power level. I like to use really long strokes in these motors to keep the rpm down." Contributing to the strength of the bottom end are the Windsor's beefy 3-inch mains. Although the main caps are anchored with just two bolts, they're much larger than the caps on a small-block Chevy and have 1/2-inch bolts (7/16 inch for SBC).

There is a downside, however, to those large mains. "Compared to the Chevy, Windsors are heavier and create more friction," says Erik. "Bearing speed can become an issue at high rpm. Smaller 2.75-inch Cleveland mains can free up 10 hp on a 1,000hp motor, but friction really isn't that big of an issue on a low-rpm motor like this." Making the deal even sweeter is that 351 Windsor long-blocks can be picked up at junkyards for $50 to $100 all day long. During its production run of nearly three decades, it powered everything from full-size trucks to Crown Vics, so junkyards are well-stocked with Windsors.

Although we didn't intend to do so by any means, we can see how some Bowtie diehards might interpret this story as Chevy-bashing propaganda. However, that simply isn't the case. Most of the time, it's always easier to build a Chevy-and probably make more power in the process-but in the world of big-inch small-blocks, the 351 Windsor has irrefutable advantages over the venerable SBC. HK Enterprises isn't some Ford specialty shop trying to covertly push an agenda, either. It builds five times as many Chevys as Fords, and actually specializes in GM Gen III and LT1 small-blocks. The bottom line is that this 418 was built for $8,200, complete from carb to oil pan. Dollar per hp for a true street/strip motor, that's tough to match, even with a Chevy.

DYNO RESULTS 418CI WINDSOR RPM TQ HP RPM TQ HP 4,800 515.1 470.7 6,200 515.4 608.4 4,{{{900}}} 523.4 488.3 6,300 521.4 625.4 5,000 528.2 502.9 6,400 513.4 627.7 5,100 538.0 522.5 6,500 514.4 636.7 5,200 536.4 531.1 6,600 509.8 640.6 5,300 538.2 543.1 6,700 503.5 642.3 5,400 538.6 553.8 6,800 497.7 644.4 5,500 537.0 562.3 6,900 491.7 646.0 5,600 540.8 576.6 7,000 488.9 651.5 5,700 537.9 583.7 7,100 489.2 661.3 5,800 531.0 586.4 7,200 481.6 660.2 5,900 532.3 597.9 7,300 482.2 670.2 6,000 525.8 600.7 7,400 469.1 660.9 6,100 525.8 610.7 7,500 453.9 648.2 PARTS LIST - 418 CI WINDSOR Item: Source: Part No: Cost: 351 block: junkyard none $100 Crankshaft: Eagle 435141006200 $495 Rods: Eagle CRS6200B3D $375 Pistons: Wiseco custom $695 Rings: Wiseco Custom $85 Main bearings: Federal Mogul 130M $55 Rod Bearings: Clevite CB633H $55 Cam Bearings: Clevite SH510S $15 Camshaft: COMP custom $225 Timing chain: Ford Motorsport {{{M}}}-6268-A302 $65 Lifters: COMP 838-16 $330 Pushrods: COMP 7956-16 $125 Rockers: Probe 11313 $500 Heads: AFR 1451 $1899 Head gaskets: Fel-Pro 1133 $150 Head bolts: ARP 154-3603 $54.50 Oil pump drive: ARP 154-7901 $16.75 Damper bolt: ARP 150-2501 $18.75 Oil pump bolt: ARP 150-6901 $6.50 Cam bolts: ARP 254-1001 $5.00 Intake manifold: Edelbrock 2924 $280 Intake gasket: Fel-Pro 1262 $19.25 Oil pan: Canton 15-694 $275 Oil pump pickup: Canton 15-695 $47.50 Dipstick: Canton 20-{{{850}}} $22.50 Oil pump: Melling 10833 $47.75 Timing cover: HKE custom $92.50 Damper: Professional Products 90007 $190 Carburetor: Holley 80514 $750 Distributor: MSD 8584 $225 Plug wires: MSD 31389 $75 Water pump: Moroso 63585 $260 Machine Shop Labor Operation: Source: Cost: Bore/hone: HKE $225 Line hone: HKE $125 Clearancing: HKE $100 Balancing: HKE $150 Grand Total: $8,155