It had to be done. In one corner of the shop was our fresh 4.3L Chevy V-6 (see "The 3/4 350," Aug. '02), and at the other end was Vortech's new centrifugal supercharger system for carbs ("Vortech Blower for Carbs" in the same issue). Bringing the scenario to its logical conclusion, one would have to meet the other. The Vortech system was designed for the small-block V-8, but in our sick dreams, there was no reason it wouldn't bolt right up to the sawed-off six. We couldn't stand it until we proved ourselves right--so we did, and ended up with 501 hp and 437 lb-ft in the process. We also got greedy and managed to puke a head gasket at 12 pounds of boost.

Let's review. The 90-degree, even-fire V-6 in question shares much of its design with the small-block V-8, which is why the blower bracket bolts to the head and why the pulley setup works. Our lil' puppy is 0.060-over for 270ci with Speed Pro LW2256 forged pistons for 9.1:1 compression, and for beef it's got Milodon rod bolts, main studs, and a windage tray. The ported stock heads use Milodon 2.02/1.60 valves bumped by Comp Cams' biggest V-6 hydraulic roller, a 280HR with 224/224 duration at 0.050, plus Comp Pro Magnum 1.6:1 roller rockers for 0.560 lift. The manifold is an Edelbrock Performer, and in naturally aspirated trim we made 301 hp at 5,500 rpm and 316 lb-ft at 4,400 with a 650-cfm Mighty Demon carb. That's through dinky, 15/8-inch-tube Hooker S-10 headers.

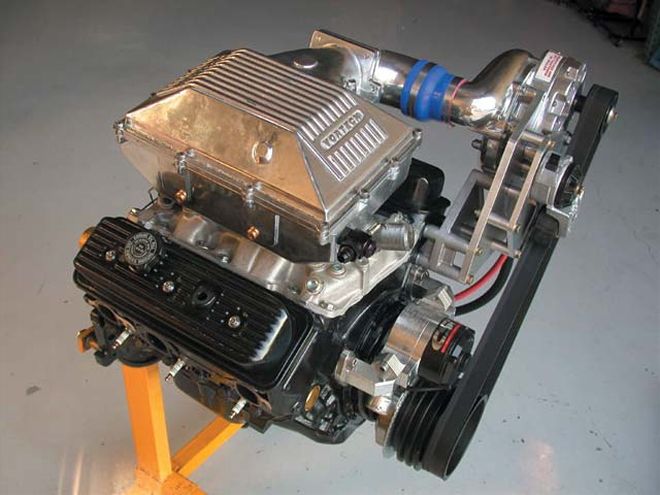

01. To make the V-8 Vortech supercharger kit fit the 4.3L V-6, all we had to do was whack the inlet elbow shorter by about 11/4 inches to make up for the lack of engine length thanks to the two missing cylinders. Other than that, the supercharger outlet can be clocked to meet up with the inlet elbow to adjust for varied manifold heights.

01. To make the V-8 Vortech supercharger kit fit the 4.3L V-6, all we had to do was whack the inlet elbow shorter by about 11/4 inches to make up for the lack of engine length thanks to the two missing cylinders. Other than that, the supercharger outlet can be clocked to meet up with the inlet elbow to adjust for varied manifold heights.

Bench racing ensues. When we tested the Vortech S-Trim setup on our HT383 crate engine, power jumped from 476 naturally aspirated to 675 on 8 pounds of boost and 91-octane 76 Performance Products pump gas. Applying the same math--a 42 percent increase, or 1.76 hp per cubic inch--it looked like the 270ci wee 6 would make something like 425-475 hp. But it seemed like 500 hp was the magic number, and we were willing to see what it would take to get there.

We bolted the Vortech blower to our Vortec engine and added Electomotive's HPX direct ignition system because a distributor would not clear the carb enclosure. Everything else was exactly as it had been on the 383 V-8, including the 6-inch crank pulley and 2.95-inch blower pulley; this combo made a bit over 8 psi at 6,000 rpm on the V-8, so we anticipated much more on the V-6 with 112 fewer cubes. We even used the 383's 750-cfm Mighty Demon carb with 88/97 jetting and the secondary high-speed air bleeds cut down from 0.040-inch to 0.028. Remember that the pressurized carb box requires a boost-referenced fuel system so that fuel pressure increases in direct proportion to boost. We fooled with the V-6 timing and discovered that it liked 32 degrees total under boost on 76 Performance Products 100-octane pump gas. Then we whacked it good, and much to our delight, the little sucker made 475 hp at 5,800 rpm with a peak boost pressure of 9 psi.

As we noted with the Vortech on the HT383 engine, the rpm at peak horsepower and torque increased with the blower's ability to continue to deliver airflow as rpm climbed. In fact, the V-6 kept making more power the higher we revved it. It was a rare circumstance where the hydraulic lifters didn't float around 6,200 rpm, and the blower kept making boost until, on one glorious pull, the V-6 made 501 hp at 6,200 rpm and 439 lb-ft at 4,800. Then we tried another at 6,400 rpm and gacked the head gasket. You can't really blame it: We were cramming 12 psi into the poor engine and asking it to deliver a power increase of 70 percent over the baseline. That's about when stuff breaks.

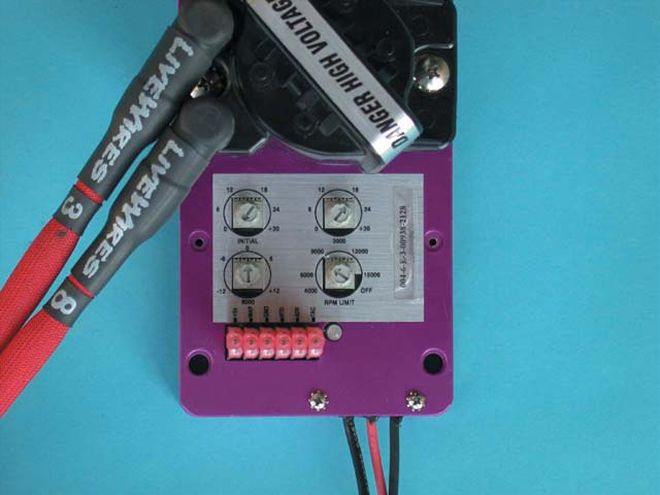

05. Here are the adjustment dials on the HPX. Once the crank trigger is set and the engine runs, you set the Initial knob to 0 and check the timing. Ours was 12 degrees--therefore, all the remaining timing numbers on the dials must be considered cumulative. For example, the Initial knob was set to 3 degrees to achieve 15 degrees initial timing (12 plus 3), and the Total knob was set to 20 degrees for 32 degrees of total timing (12 plus 20). It's all very easy once you mess with it. The HPX also has a built-in rev limiter and a timing retard that can be triggered by rpm or with an external switch (for nitrous or boost, for example). We used Performance Distributors Live Wires plug wires.

05. Here are the adjustment dials on the HPX. Once the crank trigger is set and the engine runs, you set the Initial knob to 0 and check the timing. Ours was 12 degrees--therefore, all the remaining timing numbers on the dials must be considered cumulative. For example, the Initial knob was set to 3 degrees to achieve 15 degrees initial timing (12 plus 3), and the Total knob was set to 20 degrees for 32 degrees of total timing (12 plus 20). It's all very easy once you mess with it. The HPX also has a built-in rev limiter and a timing retard that can be triggered by rpm or with an external switch (for nitrous or boost, for example). We used Performance Distributors Live Wires plug wires.

One solution would be to add copper head gaskets and O-ring wire (SCE Gaskets makes 'em for 4.3Ls) and keep throttling, but it would be more prudent to fling a bigger blower pulley on there to calm down the boost, then be happy making a stone-reliable 450-475 hp all day long on 91 octane. Put that in your S-10 and smoke it.

The Shriek of PowerRPMHPTORQUE3,500245.2367.93,{{{600}}}253.7370.13,700264.2375.03,800275.0380.03,{{{900}}}287.4387.14,000299.3393.04,{{{100}}}311.2398.64,{{{200}}}321.8402.54,{{{300}}}331.4404.84,400340.7406.74,500349.5407.94,600362.1413.44,700371.4415.14,800380.8416.74,900391.5419.65,000401.6421.95,100414.9427.35,200424.3428.55,300434.8430.95,400445.4433.25,500454.8434.35,600461.5432.95,700467.4430.75,800475.1430.25,900480.6427.86,000488.2427.46,100495.9426.96,200501.4427.4