There are several ways to go about creating a budget electronic fuel injection (EFI) system. The problem always comes down to how much you're willing to spend. Generally, the least expensive aftermarket ECM and wiring harness combinations start at around $1,000 and go up from there. Recently, we ran across what has to be the least expensive way to get into a truly programmable EFI system. Called the MegaSquirt, it's available through two East Coast hot rodders, Bruce Bowling and Al Grippo, who decided to offer an inexpensive EFI package that anyone could build.

Condensed to its essence, the MegaSquirt system is a truly build-it-yourself EFI computer. Bowling and Grippo will sell you the entire electronics package for roughly $225, and you solder it all together. Once you've assembled it, you can also build a bench-tester to ensure your box works, then you can install it on virtually any engine from a single-cylinder weed-wacker to a 12-cylinder Formula 1 engine. The MegaSquirt system we experimented with commands only the fuel system, leaving the ignition to be controlled however you wish. That's a very simplified overview. Because the whole MegaSquirt story is more complex, we've had to edit this story down to the major bullet points in order to make it fit. That means we're only going to show you the highlights of this kit. But we will get into how it worked for us, our dyno-testing, and how you can get started on a similar system.

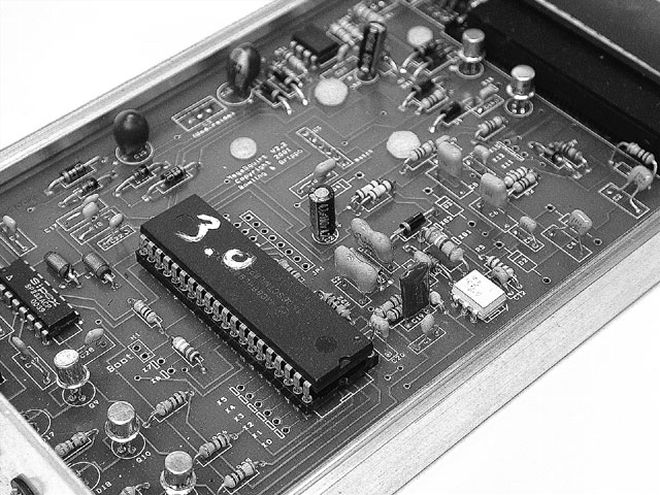

The KitIf you're old enough to remember the Heathkit build-'em-yourself radios that came in the mail as a pile of electronic parts, that's exactly how the MegaSquirt system arrives at your door. There are a couple of aluminum boxes along with a stack of circuit boards, relays, drivers, diodes, capacitors, and all other sorts of tiny electronic pieces. We're not that good with electronics, so we convinced our pal Tim Moore to sit down and solder in all those tiny connections, which he accomplished in roughly eight hours by following the instructions!

The computer is designed to operate in either an alpha-N or speed density mode. The alpha-N mode is intended for engines with very large camshafts that make using a manifold absolute pressure (MAP) sensor difficult. The speed density mode is far more popular, and it uses the MAP sensor to help establish engine load along with a throttle position sensor (TPS). The MegaSquirt system also employs the popular and inexpensive GM-based sensors such as the TPS and manifold air temperature (MAT) sensors, except for the MAP sensor, which is a dedicated sensor built into the MegaSquirt box.

Assembling the computer will also expose you to all the nuances of EFI and is an outstanding opportunity to learn how these systems function. The MegaSquirt system requires a separate computer like a laptop to tune the system once it is operational. This may seem like a much larger added expense, but the laptop is only necessary when first configuring the system. Once your tuning is complete, the laptop is not necessary for daily operation. We all know someone who owns a laptop that can be borrowed for the tuning process to reduce expenses.

Once Tim completed the assembly of the MegaSquirt, he opted to build the stimulator box that allowed him to bench-test the MegaSquirt to ensure that it worked. Tim also then downloaded the free software from the MegaSquirt Web site that would allow us to configure the computer for the engine we would be testing. In keeping with the budget approach of this system, we decided to test the MegaSquirt on a basic small-block Chevy. Rather than invest in an expensive aftermarket fuel injection manifold, we dug up a used TPI manifold from an '87 Camaro that Tim purchased for $200 at a local swap meet.

Since a couple of the TPI tubes had been mangled, we also decided to spice up the intake with a set of SLP runners and a new set of fuel injectors. Since we were purchasing new injectors, we decided to go with larger 38-pound-per-hour (lb/hr) injectors that would allow us to make more horsepower with this same MegaSquirt system. The new injectors were the most expensive single component of our swap at $420, but there are less expensive alternatives. For example, Olds Quad 4 injectors are capable of significant fuel flow and are boneyard cheap. Spend $10 apiece to clean them and you have a performance injector for a ton less cash. The MSD 38-lb/hr injectors will easily support 540 hp at an 85-percent duty cycle with a brake specific fuel consumption (BSFC) of 0.48. Factory 305 TPI manifolds came with 19-lb/hr injectors (the 350 engines used 22-lb/hr units) that are only good for around 270 hp at the same efficiency level.

Test TimeWe loaded up our trusty small-block Chevy and headed for Westech Performance where we bolted the 355 up to the dyno and, after some mild difficulties, created a carbureted baseline for the engine. That's when the fun stopped. After bolting on the TPI manifold, the engine struggled but never ran correctly despite our efforts. We discovered we really weren't ready to test the system because we hadn't spent enough time reading the MegaTune instructions. Eventually we also realized we had not loaded the base fuel map into the new chip we installed (see the "Installer Errors" sidebar-it's high comedy). Eventually we ran out of time and packed up our small-block and headed back to the barn.

Later, we regrouped and headed to Ken Duttweiler's facility for another shot at the dyno. This time, the engine fired right up and ran pleasantly, responding to tuning changes for a short time before an errant ignition ground caused us some grief. Once that was repaired, the MegaSquirt system responded instantly to tuning changes and within a few minutes we had tuned the entire wide-open-throttle power fuel map, making an impressive 450 lb-ft of torque with the almost-stock TPI manifold and SLP runners. We also quickly tuned the idle air-fuel and a portion of the part-throttle map before calling it a day.

ConclusionDespite some initial skepticism, it's clear that this MegaSquirt system works extremely well, becoming easy to work with once we learned how to navigate through MegaTune. There's a bunch of detailed material that isn't in this short story due to space constraints, so it's worth going up on MegaSquirt's Web site to dial yourself into all the details involved with this program. The biggest thing we learned from this project was that the system works as advertised, but that the overall project required a little greater investment than we anticipated. If you already have a complete EFI manifold with injectors, this will dramatically reduce the overall cost. We would suggest doing a cost estimate first before diving in if you're planning on spending less than $1,000 to complete a system. It's also important to note that we did not include the cost of building a high-pressure fuel delivery system.

Overall, we feel our MegaSquirt effort was successful, it worked as advertised, it is the least expensive system on the market, and it's a great way to immerse yourself in the world of EFI. The system has its limitations, as you might expect, but it will make power and do the job for a whole bunch less money, especially if you're good at shopping for parts. If you look at the MegaSquirt system as a great entry-level EFI system that will teach you all kinds of things about EFI, then you've got the right idea.

Get StimulatedOne of the options for building the MegaSquirt system is to also construct something called a MegaSquirt Stimulator. This slick little tool is a simple signal generator that uses a circuit board and five potentiometers that operate like volume control knobs on your stereo to create signals that simulate engine rpm, MAP, coolant temperature, throttle position, and inlet air temperature voltage output. By connecting the stimulator to the MegaSquirt computer along with a laptop, you can use the MegaTune software to evaluate the signals from each of the five inputs to ensure that the MegaSquirt ECU is performing properly.

We used the stimulator box several times to evaluate the MegaSquirt when diagnosing engine problems. In all but one case, the stimulator box proved the computer was fully functional and our difficulties were caused by outside problems (see sidebar "Installer Errors"). The stimulator turned out to be a wonderful diagnostic aid we used several times to prove that the ECU was not the problem-even when we were convinced it had to be bad!

Wide-Band TuningThe only issue we never fully resolved with our quick evaluation of the MegaSquirt was too-lean readings from our three-wire, heated oxygen sensor. Luckily, we had decided to also use our new Innovate Motorsports wide-band oxygen sensor to help us tune the 355ci small-block. When the narrow-band oxygen sensor didn't agree with the Innovate unit, we ignored the narrow-band sensor completely. Time didn't allow us to go into why that unit failed, but it may have been just a poor sensor or perhaps a wiring problem with the sensor. The MegaSquirt circuit certainly performed as intended.

The beauty of using the Innovate system is that we were able to quickly establish best power using the air-fuel ratio sensor to hone in on best power. At first we aimed for 12.5:1 and then relied on power output to lean the mixture out to around 12.9:1 for best power. Still using the wide-band sensor, we also partially tuned the midrange cruise to run around 15:1 for best highway fuel economy and also used the feedback from the unit to set the idle air-fuel at 13.5:1 where the engine seemed to be the happiest.

The MegaSquirt is intended to use the narrow-band oxygen sensor to run in closed loop, and if our sensor had cooperated, it's clear the system would have worked just fine. But for wide-open-throttle tuning, the Innovate Motorsports wide-band sensor sure made it easy to get us close to best power with its accurate air-fuel information. After three quick back-to-back full-power runs, we had peak power dialed in with a few keystrokes on the computer.

Installer ErrorsHere's where we come clean. Did this installation go as smoothly as it might appear? Absolutely not. But that's not because the MegaSquirt is a difficult system to master. Granted, this is not a system for the entry-level car crafter who barely knows one end of a screwdriver (or injector) from the other. But neither is this system overly difficult. The difference is that with this budget-based system, the designers are letting you do more of the work. What do you expect for $225?

We did have difficulties, but almost all of it was self-inflicted. The reason the engine was tested on two different dynos is that during our original test at Westech, we had engine-related problems that complicated our attempts with the carbureted baseline. Eventually we discovered that in earlier work on this engine I had placed a solid lifter on the intake lobe of Number 2 cylinder that kept the intake valve open and killed the power. Once we fixed that problem, we ran into trouble getting the injected version to run. We discovered an intermittent connection problem with the chip that showed up when we checked operation with the stimulator. We replaced it with a spare chip Tim had thoughtfully purchased for $10. However, the engine still wouldn't run properly and we ran out of time. Later, Tim discovered that we had forgotten to load the base fuel map onto the second chip!

Dyno-testing at Duttweiler looked like it would be a cakewalk, and at first the engine fired right up and ran well with the base VE map. But suddenly, the engine would run rough, misfire, and quit. Since MegaSquirt doesn't control spark, our setup included an MSD billet distributor and an MSD 6A controller. Since the MSD box does emit electro-magnetic noise, we thought that might be the problem. Eventually, we traced the intermittent problem to the white wire on the MSD box occasionally grounding out to the tray on the dyno! Once we insulated that wire, the engine ran like a champ!

The point of all this is that only once was there a problem with the MegaSquirt and that was quickly rectified. The rest of our problems were self-inflicted, yet we still kept thinking that the source of our frustration was the MegaSquirt computer. The lesson here was that we tend to blame the stuff that we don't understand, when usually it's some dumb mistake that we've made that has nothing to do with the black box. This is a lesson that was hard-earned and worth remembering.

Parts ListThe following is a list of the parts we used to build the MegaSquirt system and run it on the engine. It's a little confusing, because you purchase Printed Circuit Boards (PCBs) from MegaSquirt, but the rest of the electronic parts are from a separate company called Digi-log. It's all on the MegaSquirt Web site. Prices for all MSD and SLP products were taken from www.summitracing.com.

Component Manufacturer PN Price ECM board MegaSquirt MSPKIT $120.00 Digi-key parts Digi-log - 51.40 {{{Relay}}} board kit MegaSquirt RELAYPCB 15.00 Relay board parts Digi-log - 38.91 Stimulator box MegaSquirt STIMPCB 20.00 Stimulator parts Digi-log - 21.92 Injectors, 36-lb/hr MSD 2018 421.00 Injector harness MSD 2400 15.00 Coolant sensor MSD 2310 12.00 Air inlet sensor MSD 2320 17.00 Oxygen sensor, heated three-wire MSD 2330 73.00 Bung for oxygen sensor MSD 2335 19.00 MSD 6A box MSD 6200 150.00 Used TPI manifold pre-owned - {{{200}}}.00 Misc. wiring and parts - - 50.00 Performance-tuned runners SLP 20002 260.00 Gasket set SLP 20030 20.00 Total $1,504.23If you cleaned a set of used injectors, reused original sensors, and passed on the MSD box and SLP runners, you could get this price down to around $600, and that's assuming you're starting with a clean slate.

This is a volumetric efficiency (VE) table we generated using the MegaTune software for a 350ci engine idling at 900 rpm with no more than 15 inches of vacuum. We estimated peak torque at normally aspirated 440 lb-ft at 4,000 and peak hp at 375 at 6,000 rpm. We loaded a similar table into our engine, and it fired right up and ran respectably while we fine-tuned it for best power. The numbers in this VE table represent the percentage of cylinder filling. To enrich the mixture, increase the number value in the corresponding box. The vertical scale is load (expressed in kPa or kilopascals-metric for pressure where 1 kPa = 0.145 psi). The horizontal scale is rpm.

kPa (load) Idle 28 42 67 81 87 83 79 75 28 43 69 83 {{{90}}} 86 82 78 28 45 73 88 95 90 86 82 28 46 75 90 97 93 88 84 28 49 79 95 102 98 93 88 28 50 81 97 105 {{{100}}} 95 90 29 52 84 102 110 105 100 95 30 54 86 104 112 107 102 97 WOT RPM 0 1,{{{200}}} 2,000 2,500 3,000 4,000 5,000 5,500Dyno ResultsA major portion of the evaluation of the MegaSquirt was to assemble the EFI computer and then test it on the dyno. We decided to run the engine first with a carburetor, which is listed as Test 1. The engine was a 355ci small-block Chevy with 9.5:1 compression, forged Childs & Albert pistons, Edelbrock Performer RPM aluminum heads, and a Victor Jr. single-plane intake with a 750-cfm Barry Grant Speed Demon carburetor.

For the EFI test, we purchased a used TPI manifold and plumbed in a new set of MSD 38-lb/hr injectors and SLP runners to ensure sufficient fuel and airflow for this small-block. Since the TPI manifold was designed as a torque piece, the test was not about making horsepower but instead to show that the MegaSquirt could perform as intended. Had we outfitted the Victor Jr. with injector bungs, we feel confident that the power numbers would have been very similar. Overall, the test was a complete success.

TEST 1 TEST 2 RPM TQ HP TQ HP 2,{{{600}}} 375 179 425 210 2,800 377 193 434 231 3,000 387 221 435 248 3,{{{200}}} 396 241 440 268 3,400 400 259 448* 290 3,600 403 276 443 304 3,800 407 294 437 317 4,000 410 313 429 327 4,200 414 331 421 337 4,400 419* 351 410 344 4,600 417 365 400 350 4,800 413 378 386 353* 5,000 408 389 368 351 5,200 403 399 344 341 5,400 396 408 - - 5,600 388 414* - -