What's in the blue box? A 360 crate engine rated at 380 hp, ready to run. Will it turn the number? We'll find out.

What's in the blue box? A 360 crate engine rated at 380 hp, ready to run. Will it turn the number? We'll find out.

Chrysler's 380hp crate small-block has become a popular choice for those looking to pop the lid on that big blue box and pull out a stout small-block ready to turn a number. With a rated output of 380 horsepower, and a remarkably flat, and fat, torque curve, the 380/360 has gained recognition as a strong performer. We've seen numerous crate-equipped A-Bodies deep in the 12s with box-stock crates, and in anyone's book, that's fast enough to make the grade as a musclecar engine. The Mopar small-block crates have justly earned a reputation as quality engines at a bargain price, and with reportedly the lowest warranty return rates in the industry, Mopar Performance has this combo down pat.

Brule Talks <strong>Brule Talks</strong><br>When we're in for a dyno test, we always look forward to hearing dyno operator and fellow tuner Steve Brule elucidate our latest subject. We can't think of anyone who's run, tested, and tuned more hardware and combos than "Brullio." In his words,"That's a nice crate motor Mopar's putting out . torque's just where it should be for an engine of this type and size. It pulls strong with a very smooth power curve through the rpm range . no hiccups in the torque band right to and past peak power. This shows the valvetrain combo is well matched-not always the case with a hydraulic roller engine . and did you notice, not a wisp of blow-by?"With all the other brands that go through this shop, we're always proud when a Mopar proves its worth. Now if we could only find him that '67 GTX like the one he had back in the day

<strong>Brule Talks</strong><br>When we're in for a dyno test, we always look forward to hearing dyno operator and fellow tuner Steve Brule elucidate our latest subject. We can't think of anyone who's run, tested, and tuned more hardware and combos than "Brullio." In his words,"That's a nice crate motor Mopar's putting out . torque's just where it should be for an engine of this type and size. It pulls strong with a very smooth power curve through the rpm range . no hiccups in the torque band right to and past peak power. This shows the valvetrain combo is well matched-not always the case with a hydraulic roller engine . and did you notice, not a wisp of blow-by?"With all the other brands that go through this shop, we're always proud when a Mopar proves its worth. Now if we could only find him that '67 GTX like the one he had back in the day

Based on the production Magnum 360, the 380-horse crate is built with all-new parts, not the usual rebuild. Inside the bottom end you'll find pump-gas-friendly 9:1 pistons, a hydraulic roller cam, and a double-roller drive. The roller is a fairly stout stick, with a long .288 intake, .292 exhaust duration, and .501/.513 lift-much more than any production small-block. The specs don't hide the fact that this cam will have some bark, so if the lope, rumble, and top-end power aren't the goal, consider backing off to the milder 360/300hp version.

Topping the short-block is a set of Mopar's now-familiar high-swirl closed-chamber Magnum cylinder heads. The 1.925-inch intake valves are slightly smaller than those of the early 340, while the 1.625-inch exhaust valves are slightly larger. As with all Magnum engines, 1.6:1 rockers are standard. This is a tenth of a ratio point higher than the traditional 1.5:1 small-block rockers of old.

The major benefit of the Magnum heads over the old 340/360 castings is the nicer form in the exhaust port. The old small-block Mopar heads had a definite flow-inhibiting area in the most critical portion of the exhaust port floor, right as the port departed from the valve seat. Also restricting the exhaust flow was a big kink in the port roof. The Magnum exhaust port is much improved. On the intake side, the port window is narrow through the pushrod area, owing to the larger clearance hole used in conjunction with the hydraulic roller cam's valvetrain. Toward the valve, the Magnum head's ports take a nice form. The most significant departure from the Mopar small-block heads of old is the combustion-chamber design. The best features of the old heads were retained, including the valve angle and favorable opening axis to the centerline of the bore. The chamber has been redesigned to take advantage of the better combustion characteristic available from a modern closed-quench chamber. This chamber design alone should produce a worthy increase in output over the old-style open chamber heads.

The Magnum crates are shipped with a large cross-section single-plane M-1 aluminum intake manifold, which appears to be a nice design, utilizing a modern sweeping runner. Bosses are cast into the intake, allowing for a multi-port fuel-injection system, although a standard four-barrel carburetor is the induction of choice for most installations. The Magnum crate is fitted with a center-sump oil pan, which is compatible with traditional Mopar body styles. Rounding out the package, the crate comes equipped with MP cast-aluminum valve covers, a damper, the dipstick and tube, as well as the water pump. A complete Mopar Performance electronic ignition system and thermostat housing are included. Add a carb, headers, and accessories, and it's ready to run.

We used a set of 1 5/8-inch dyno headers, which are drilled for exhaust gas temperature probes (EGTs)-a valuable source of info when tuning.

We used a set of 1 5/8-inch dyno headers, which are drilled for exhaust gas temperature probes (EGTs)-a valuable source of info when tuning.

Having heard good things about the 380hp crate and seen them in action, we were interested in tossing one on the dyno and examining the output characteristics for ourselves. We contacted a local Mopar Performance dealer, Glendora Dodge, to see if they had any crate engines lying around wanting to kick up some dust. It just so happened they were holding one for customer delivery. We asked them to contact the customer and propose a dyno evaluation and tune of the crate, on our dime. Turns out, the customer, Tom Mociler, had some time before his '68 Dart project was ready for the new powerplant. With the blessing of Mopar Performance's big cheese, David Hakim (regarding Tom's warranty concerns), we were on.

We dutifully loaded the big blue box and headed out to our favored haunt for such hijinx, Westech Performance Group, for a run on the SuperFlow dyno. Mopar Performance claims 380-plus horsepower from this crate-not too far off the magic 400 number-so the usual pre-test jaw boning and haggling began. Just how much was in it? The engine's owner, Tom, had supplied a new 750 Mighty Demon carb, which we figured would have a favorable influence on output. He also supplied a case of Mobil 1 synthetic lube for a post break-in oil change, which is usually worth a couple of odd ponies. We had all day to run our tuning loops, with no real parts changing planned, so we'd have the luxury of time to tune it to a razor's edge. We prelubed the engine, stabbed the distributor, bolted on a set of 1 5/8-inch dyno headers feeding into a pair of 3-inch Flowmaster mufflers, hit the ignition, and the crate fired immediately. We dialed the timing to 34 degrees total for a baseline setting.

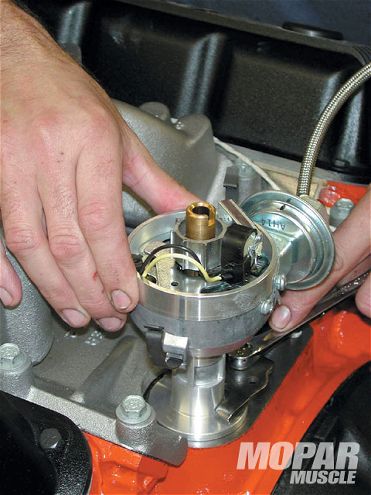

A complete MP electronic ignition is supplied with the crate, including the control unit, ballast, and wiring. We installed the distributor and hooked it to the dyno's MSD Digital 7 box.

A complete MP electronic ignition is supplied with the crate, including the control unit, ballast, and wiring. We installed the distributor and hooked it to the dyno's MSD Digital 7 box.

Dyno operator Steve Brule set the machinery to run through an automated break-in cycle, and the engine sounded sweet. It idled down easily to a steady 850 rpm, although the long-duration cam made its presence known with about 6.5 to 7 inches of vacuum. Left alone to monitor the dyno console, I goosed the throttle and found that the 360 responded sharply. Anticipation started to take hold, and we had to sneak a peek. Then, we set the load dial to 3,800 rpm and gave the control handle a tug. The raw torque counter shot up to the 375 ft-lb range, and it was obvious this thing was going to have some oats! Mr. Brule returned to the controls, and we ran a few static pulls to confirm that the fuel mixture was in the zone. It showed to be in a safe range with the box-stock Demon settings.

Showtime! We were ready for the first real pull. The controls were set for a short pull from 3,500-5,100 rpm, and we had our first numbers: 421.9 ft-lbs at 4,200 rpm, 377 hp at 5,100, and still climbing at the top of the pull. We had no doubt it would find the rated 380 number, and more.

The numbers from the dyno's readout indicated we were a little lean. We next went through a jetting loop, running several pulls and finding best power under the test conditions, stepping up to 78 primary and 87 secondary jets from the Demon's stock jetting of 75/84. With the jetting dialed in, still at 34 degrees of timing, the engine handily exceeded the rated output with 432.4 ft-lb at 4,100 rpm and 394 hp at 5,300 rpm. We were knocking on 400 hp and moved on to the timing loop. It didn't take long to find the optimal timing to be 36 degrees total, and we now cracked over the magic numbers-401 hp at 5,400 rpm and 437.7 ft-lb at 4,100 rpm. With that, we were fairly satisfied and confirmed the jetting through a second fuel-tuning loop, finding that the same 78/87 combo that worked with 34 degrees was still on the money with the timing change.

We still had the change to synthetic oil, so the sump was drained and we put in a fresh fill and filter. Several pulls later, we were still at 401 hp and a little puzzled. We checked the dyno readout carefully and noted that the oil pressure peaked at 70 psi at 5,500 rpm, and actually dropped to 68.5 psi by the end of the pull. This could have been caused by a slight aeration of the oil. A check of the stick showed the oil was slightly overfilled, and 1/2 quart was drained. The next pull showed 439.5 ft-lb at 4,100 rpm and 409 hp at 5,400 rpm. That 1/2 quart of oil was costing 8 hp! Windage was no doubt a factor, but the fluctuation in oil pressure, though slight at only a couple psi, makes us suspect that some slight aeration had occurred, which hurts performance with hydraulic lifters. We've seen it before-in some cases more obvious and dramatic.

With that, we felt that we had taken this package to its full potential. The Magnum 380 (409?) crate, with a high-end carb, tuning, and oil, was making 29 hp over its base rating. To us, that's impressive. It's no wonder those crate-equipped A-Bodies move as hard as they do. We had some time left and tried to further tune the combo with a spacer under the Demon carb. First, a 1-inch open spacer was installed, and after a few runs it was clear that it was not going to add to the combo. Power was no better anywhere in the curve, the peaks were down, and low-end took a hit. Next we substituted a four-hole 1-inch spacer, and there was a hair more torque at the bottom of the curve, but it cost power up top to the tune of 5 hp. Neither spacer complemented the combo, suggesting that the plenum volume and layout of the M-1 is well matched as-is to the rest of the combo.

We had a good time testing the 380-horse crate. The engine did what it was supposed to, delivering the power promised and then some. Open the box, bolt on a decent carb and a set of headers, and rest assured, it will make its rating or more with only a little tuning. Dial it in and there can be 400-plus horsepower on tap.

That's enough to show 'em you're serious.

We were pleased with the output and quality of the crate Magnum. No leaks, no blow-by, and over 400 hp on tap to end the great crate debate.

We were pleased with the output and quality of the crate Magnum. No leaks, no blow-by, and over 400 hp on tap to end the great crate debate.

Dyno Results

Superflow 901

Tested at Westech

Mopar Performance 360 cid 380 hp rated

RPMTQHP2500380.61813000402.92303500415.12774000437.83334100439.53434500437.13755000416.33965400398.64095500388.64076000343.9395