Our 340 put out 392 hp on the dyno, and is destined for a '70 Swinger 340 that's still a long way off. Languishing in the meantime, we thought we'd unwrap it and see if there was more power to be found.

Our 340 put out 392 hp on the dyno, and is destined for a '70 Swinger 340 that's still a long way off. Languishing in the meantime, we thought we'd unwrap it and see if there was more power to be found.

Sitting in the corner decorating our workshop was a hot little street 340 destined for the space between the rails of our '70 Swinger 340. Built-up on a budget, initially to resto-stock 340 specs, the small-block delivered 281 hp on the engine dyno. With the addition of a set of Hooker 151/48 inch headers, an Edelbrock 800 carb, an RPM Air-Gap intake, and a Comp Xtreme Energy 268 Hydraulic cam, we had a stout little 392hp 340 on our hands (See December 2000-February 2001 Mopar Muscle). The initial buildup was done for just a touch over $1,500. Even with the addition of the ported heads, this engine could be built for under 2,500 bucks. What kind of horsepower was to be gained with some simple porting and a cam change? Only the Mad Scientist knows. We were quite satisfied finding 111 hp with four bolt-ons, however, resting on our bench was a fresh set of ported small-block heads. Hmmm... Wanna take a guess where we're going with this?

Heads

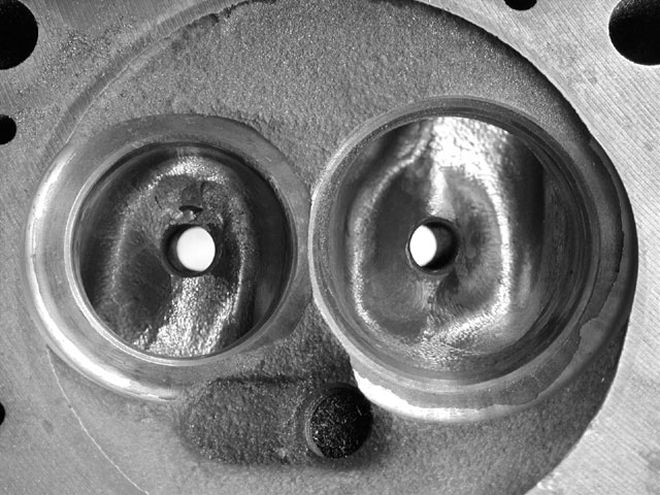

While the 340 "X" heads on our engine were the best-flowing stock small-block castings we have tested to date, the flow potential of any of the 340/360 heads are similar in ported form. Our ported heads were of humble origins, a common set of late '70s #051 smog castings from a 360. We treated them to a well-executed but basic street porting job. The list of mods began with a fresh Serdi machine-cut valve job, opening the intakes to the 340's 2.02-inch valve size. While machining the valvejob, the chamber walls adjacent to the valves were relieved with a deshrouding cut and the bowls were opened with a 75-degree cutter. The handwork consisted of pocket-porting the bowls, including reshaping the valve guide bosses; cutting a nice, smooth radius onto the ports' shortside turns; opening up the pushrod pinch point; gasket-matching the intake runners; and radiusing the hump in the exhaust port roof. We finished by polishing the combustion chambers. Nothing dramatic or exotic, but all nicely done, resulting in flow improvement (shown in Table 1). The heads picked up substantially in flow over their factory form, and handily exceeded the excellent flow of the stock 340 X heads.

Our plan was to swap the hydraulic cam and stock rockers for a solid setup and replace the resto-stock 340 "X" heads with ported factory iron.

Our plan was to swap the hydraulic cam and stock rockers for a solid setup and replace the resto-stock 340 "X" heads with ported factory iron.

The chamber mods had increased the cc's of our 360 heads by a fairly substantial 7 cc-from the stock volume of 70 cc to 77 cc. This, in itself, would have cost upwards of a point of compression on our 340. Substituting a set of Milodon's Street Valves netted a reduction of chamber volume of over 3 cc's, owing to the flat face of the aftermarket valve versus the deep-dished stock tulip shape. From there, milling the heads .030 inches brought the volume down to the stock 340 spec of 68 cc. To compensate for the milling in terms of intake manifold fit, the intake face of the heads was milled .030 inches as well. To wrap up the cylinder-head package, we cut the valve guides for P/C-style Teflon valve seals, reducing the guide height at the same time by .100 inches to allow retainer clearance for high valve lift.

Lifting The Lift

With the fatter flow curve across the board and greater peak flow, our ported heads would be capable of delivering a respectable power increase on their own. In terms of power production, the higher port flow would respond favorably to more camshaft, and naturally encourage more rpm. The Comp XE268H hydraulic cam currently in the 340 was making peak power at near 6,000 rpm with the stock "X" heads. Adding ported heads and our plan for more cam would extend this well out into the mid- to upper 6s.

Our heads boasted fairly extensive pocket porting, opening the bowls and reducing the massive guideboss to the form shown in the intake and exhaust ports here.

Our heads boasted fairly extensive pocket porting, opening the bowls and reducing the massive guideboss to the form shown in the intake and exhaust ports here.

At this point we moved to a solid lifter profile. We had recently obtained a special cam and were eager to try it out. Previously, we introduced a series of fast-rate Competition Cams solid lifter lobe profiles. These are adaptations of the technology used in the design of Comp's successful Xtreme Energy lobes, but designed to take advantage of the even quicker action possible with Mopar's .904-inch tappet diameter. These quick lobes are Comp's MM-Series solids, which are not even in the current catalog. We had run a large version of the MM-Series solid lifter profile in another engine test, and were impressed with the performance.

The hallmark of the MM-Series is the fast valve action, which obtains high lift for a given duration. We were intrigued with the idea of having a cam ground using the smallest versions of the MM lobes. The expectation was that the relatively short overall duration (seat) would allow for reasonably good street manners and idle, while the super-aggressive lobes would provide the high-lift and big upper-lift duration numbers for serious punch. These cams are all custom grinds, which requires a call to the Comp tech line for ordering assistance.

The shortside turn, the area where the port turns in from the floor to the valve seat, is vital to flow. Go for a nice rounded raduised form like the port shown to the left.

The shortside turn, the area where the port turns in from the floor to the valve seat, is vital to flow. Go for a nice rounded raduised form like the port shown to the left.

We asked for lobes #6581/6582 int/ext ground on a 110-degree lobe separation with 4 degrees of advance. These are the smallest two lobes in the MM series. With a short 265/269 advertised seat duration (checked at .020-inches), a moderate (for a solid) 239/243 int/exh duration at .050 inches, a healthy 157/161 duration at .200 inches, and a fairly serious .573/.586 gross lift with the 1.6 rockers we were planning on running, the fast lobes make the cam seem small at the bottom of the lift curve, but come on to catch a fairly big cam by max lift. In fact, conventional solids typically need to start opening the valves 15 degrees earlier to reach the same lift, with advertised seat durations (also rated at .020 inches) in the mid 290s. Would we find the power of a race cam and the manners of a hot street cam? The specs would certainly indicate an excellent trade-off between the two.

To make the change from a hydraulic to a solid, an upgrade in valvetrain components was required. Our 340 still carried its stock stamped-steel nonadjustable valvetrain and solid pushrods. The stock setup belies its simplicity and low cost by offering good performance and rpm capabilities with moderate hydraulic cams. With a solid, an adjustable valvetrain is, of course, required, and we opted for a set of billet aluminum beauties from Probe Industries. In keeping with our quick valve-action rationale, the rockers were ordered in the quicker 1.6:1 ratio rather than the stock 1.5:1. For pushrods, we ordered a set of Comp's Magnum 5/16-inch ball-cup pushrods (PN 7692) for the solid-lifter application.

Intake And Exhaust Tract Tweaking

As part of our bolt-on plan last time around, Edelbrock's Performer RPM Air-Gap manifold was mated to the 340's heads. In numerous tests, the Air-Gap has proven to be an outstanding intake for the small-block Mopar, producing terrific torque down low and belting out big power up top. Although an Edelbrock carb was used in our last configuration, it had been borrowed from the 340 several months ago, and has seen regular street duty since. This time around we bolted on one of Westech's dyno carbs-a 750 cfm mechanical secondary Speed Demon.

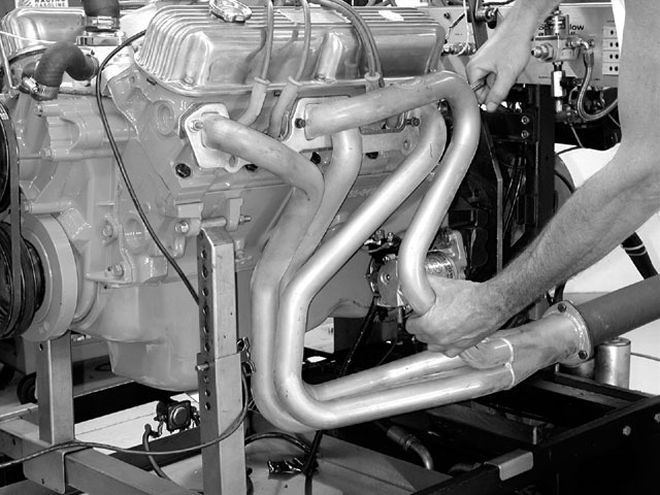

Finally, as part of our previous program, we had installed a set of Hooker's 1 5/8-inch headers-a common size for general-purpose street applications. The 340 already made 392 hp, and we were certainly expecting more with our beefed-up combo. With this in mind, it was likely that the 340 would benefit in output with a larger header. The same 1 5/8-inch street headers were bolted to the reconfigured engine, but we were packing a pair of big-tube Hooker 1 7/8-inch headers for the dyno session to come.

We painted the area around the port opening with machinist's layout dye. This product is available at most industrial supply houses, and helps make the marks on the intake more visible while porting.

We painted the area around the port opening with machinist's layout dye. This product is available at most industrial supply houses, and helps make the marks on the intake more visible while porting.

Running The Numbers

Getting more power with an engine combination gets progressively more difficult as the outright power escalates. While we felt there was still a bit of room to the upside, the 340 already produced well over 1 hp per cubic inch, at 1.13. Pushing the envelope generally comes with a higher price tag. Although a set of prepped aftermarket race heads would be the quick ticket to radical power gains, our rebuilt smog-heads came at about the same tariff as a rebuild on the original 340 heads. Since the porting was done at home, the added cost was only in time. Ditto for the manifold mods.

The solid flat tappet cam and lifter package only marginally exceeded the cost of the hydraulic grind we had previously run. Our new valvetrain was the major additional expense associated with the change in configuration. Revisiting the 340 in the search for more power did not produce a radically more expensive combination. With the added constraints of keeping the compression ratio at pump-gas levels, maintaining reasonable drivability, and not outstripping the rpm capabilities of the stock-rebuild bottom end (forged SpeedPro pistons though it is), just how much more power would we wring from this combination?

Our baseline configuration included the ported factory 051 casting heads, the small 1 5/8-inch Hooker headers, Comp's solid cam installed at 104-degrees intake centerline, with a 750 Demon carb topping the Air-Gap intake. After cam break-in, dialing in the timing, and checking jetting, we were ready to run for the numbers. The engine responded favorably to our modification plan, belting out 427 lb-ft of torque at 4,600 rpm, and 458.9 hp at 6,300. Right out of the gate, our newly modified 340 was making 1.32 hp per cube, while delivering a steady 850 rpm idle with around 9 inches Hg of vacuum. Our mods increased output by 17 percent over our already hot 340 combo, with power up noticeably throughout the test range. The engine came on stronger and kept pulling well past where the old combo ran out of steam.

Our intake was matched to a standard FelPro gasket, as were the heads. It's important to get the gasket perfectly centered with the intake. We wrapped some tape around the bolt threads to provide a tight, well-centered fit into the intake bolt holes. Scribe the outline of the gasket opening.

Our intake was matched to a standard FelPro gasket, as were the heads. It's important to get the gasket perfectly centered with the intake. We wrapped some tape around the bolt threads to provide a tight, well-centered fit into the intake bolt holes. Scribe the outline of the gasket opening.

We were running a set of Autolite #63 spark plugs, and had some of Denso's Iridium rare-metal electrode sparkplugs. Designed to fire-through under extremely demanding ignition requirements such as high-boost blown or fuel applications, they are extravagant in a normally aspirated street engine such as our 340, and certainly not cheap in comparison to a conventional plug. We were curious, however, as to whether they would benefit performance. We found the Iridium plugs added about one horsepower to the peak number, but more interestingly, they added a 5-8 lb-ft (over three runs) advantage in the first few hundred rpm of our test range. We left them in for the rest of our test session.

In numerous tests with the Performer RPM Air-Gap intakes, we have often seen a peak power gain with the addition of a 1-inch open spacer under the carb, particularly with higher horsepower engines. We figured adding one to our 340 would nab a few extra ponies for little effort.

The carb spacer paid off, raising peak output to 433.8 lb-ft at 5,000, and 464.9 hp at 6,400. Power was up noticeably in the upper end of the power band, at the expense of some torque lower in the range. Most striking was the way the spacer helped the engine carry power past peak. At 6,600 rpm, the spacer was worth 25 hp, and carried usably to 6,800, while without it power dropped more sharply.

Up to this point we were still running the 1 5/8-inch street headers, and at 465 hp they seemed kind of small. We bolted on our 1 7/8-inch Hooker Super Competition headers to see if the small tubes were, indeed, costing some output. The result was a trade-off, with power added to the top with a similar amount deducted off the lower end of the range. Peak output was up impressively to 477 hp at 6,500 rpm, with torque reading 431 lb-ft at 5,100. Looking at the averages over the entire curve from 3,500-6,800, it was an exact trade, with the data reading within 1/10 of a horsepower between the two tube sizes over the full rev range.

Loaded onto the Westech dyno, we bolted on the 1 5/8-inch headers. The changes to our previous 392hp combo were the cam and valvetrain, an MSD distributor, the carb, and the heads.

Loaded onto the Westech dyno, we bolted on the 1 5/8-inch headers. The changes to our previous 392hp combo were the cam and valvetrain, an MSD distributor, the carb, and the heads.

Would a single-plane intake prove better? We bolted on a modified Torker II single-plane to find out. This particular intake had been a proven power maker for us in the past, especially in the upper rpm range on similarly powerful small-blocks. Not this time. Output was down over 20 lb-ft at the start of the pull, and widened to as much as 30 lb-ft. The gap narrowed approaching peak horsepower, but even peak horsepower was down by a solid 15. It was totally unexpected, and we still can't explain it, but it was real. The combination of cam timing, heads, and headers just became unhappy with this intake. Quite peculiar. An interesting note was that the idle vacuum was down a significant 1-1.5 inches Hg with the single-plane, and idle quality deteriorated noticeably. We reinstalled the Air-Gap to find vacuum back up, the idle smoothed out, and power right back in line at 477 hp.

Were we happy? Frankly, we considered the milder version of this engine a fine street mill with 392 hp on tap. The Comp XE268 hydraulic cam used in that combo is a nice street grind, and driving one daily for 60,000 miles in my 318 '69 Dart has been convincing evidence of that. This combo, with the solid cam, produced 1.38 hp per cube from our 340 on Unocal 91 octane pump gas-a remarkable output through a set of mildly ported Cordoba smog heads. Getting that done while maintaining reasonably good idle quality, 9 inches of vacuum, with only 346 cubic inches, tells us these new MM solid grinds are pretty extraordinary.

Hmmm.... It will bolt right in place of that 318 in the '69 Dart while the '70 Swinger gets built.... Wanna guess where we're going with this?

We used one of Westech's dyno carbs-a reliable 750 mechanical secondary Speed Demon.

We used one of Westech's dyno carbs-a reliable 750 mechanical secondary Speed Demon.

Manifold Mods

We were going to run a set of ported heads, and as part of the porting program, the intake port openings were matched to standard 340/360 gasket size. Production intake manifolds are generally finished somewhat undersized at the port exits. A mismatch wherein the intake is smaller than the heads has little negative effect, while a mismatch where the intake is larger than the head will leave a stepped obstruction in the direction of flow at the joint. Since head port openings are typically cast somewhat undersized, the manifold is likewise made undersized to lessen the risk of an undesirable mismatch. A port match will increase the area available to flow and offer the smoothest transition from the intake into the heads. Here's how we did ours, as easy as 1...2...3.

Basic Porting

Although the porting job on our smog heads was basic, it really was the culmination of a great deal of experience with these ports. The mods were described in the text. The experience and form are best shown in a few pictures here. We limited polishing efforts to where it does the most good, namely at the shortside turn, and left the rest of the port in the raw-cut state. Actually, much of the runner was left untouched by the cutter.

Corrected Brake Torque

Superflow 901 Dyno

Tested At Westech

Corrected HP

Superflow 901 Dyno

Tested At Westech

Bold Numbers Are Peak

Base 1: 340 as originally tested; stock build, stock 340 "X" heads, Comp XE268H cam, Air-Gap intake, 800 Edelbrock carb, 151/48-inch Hooker headers, stock valvetrain, stock electronic ignition

Base 2: Reconfigured 340; as above with street-ported #051 heads, Comp custom MM-series solid (lobes 6581/6582 110 LSA), Comp 7692 Magnum pushrods, Probe 1.6:1 Roller Rockers, 750 Speed Demon carb, MSD distributor

Plugs: Swap Autolite #63 for Denso Iridium #IQ24

Space: Add 1-inch open carb spacer

HDR:Replace Hooker 1 5/8-inch primary tube headers with 1 7/8-inch primary Hooker Super Competition headers

#051 Head Flow Tested At 28-Inches Of Water.

Superflow 600 Bench

Ported By Steve Dulcich

Tested By Steve Dulcich