By the time Edelbrock's new aluminum big-block Mopar heads were introduced at the SEMA show last year, we already had a close-up look at the new aluminum castings at the Edelbrock's design and research lab. We reported those initial impressions in the Feb. '01 issue of Mopar Muscle and were generally pleased with the design. It wasn't the shiny-silver look of a fresh aluminum head that grabbed us, though; what really made them interesting were the nicely shaped port and bowl forms, the quench combustion chamber, and the deeper, angled spark-plug position. The clincher was when the factory engineers said, "Go for it!" when asked if we could run comparison flow bench testing versus a standard No. 906 casting. That final tally showed 291 cfm of intake airflow (against 233 cfm for a stock No. 906 casting) and 223 cfm versus 171 cfm on the exhaust side. It seemed as though some power would be had here.

While the design changes were obvious and the flow numbers looked promising, the bottom line is how they stack up in power production on the dyno. We already had a fresh '71 440 Six Pack motor on the stand (see sidebar, Builder's Notes-The Combo), so we ordered a set of the new Edelbrock pieces and headed to the Westech dyno. The rules were simple: start with a stock set of No. 906 heads, swap to an out-of-the-box set of Edelbrocks and see if they deliver the goods. Moreover, we brought along a couple of different Edelbrock intake manifolds, the old standard high-rise TM-7 single-plane, and the more recent Performer RPM two-plane. We'd run both intakes on both sets of heads and let the numbers tell the tale.

Baseline Our baseline combo consisted of our stout Comp Cams solid street roller- equipped Six Pack short-block with the ubiquitous No. 906s up top. The heads had the production valves and were unported, though a quality rebuild was performed, including a precision race-type valve job and a minor blend of the sharp bottom cut in the bowl. In other words, cheater No. 906's, but they were the stockest fresh heads we had available and representative of a well-detailed set of production units. Since we were running a solid roller cam, the appropriate dual valvesprings were installed to achieve the required spring loads and were bolted on with fresh Fel-Pro head gaskets. On the entry side of the heads, we installed the Performer RPM intake crowned with an 850-cfm annular discharge booster Speed Demon carb; on the exit side we bolted up a set of tti 2-inch primary headers.

After a few base pulls to establish the jetting (it turned out nearly dead-on out-of-the-box), we had the first numbers on our 440: 483 hp at 5,500 rpm and 529.7 lbs.-ft. of torque coming in at 4,000 rpm. Even with the relatively stock heads, the 440 was making serious power for a street engine. Credit the excellent Comp roller cam.

Next, we swapped to the TM-7 single-plane, an ancient design race single-plane that's still available new from Edelbrock. A retest with the intake change showed that power was down across the board when compared to the Performer RPM, with the figures now coming in at 517 lbs.-ft. at 4,100 rpm and 471 hp at 5,400 rpm. We already knew from previous dyno testing that the Performer RPM is tough to beat, even with a good single-plane intake, so the old TM-7 didn't have a chance, especially in the under-6,000-rpm power range of this street engine.

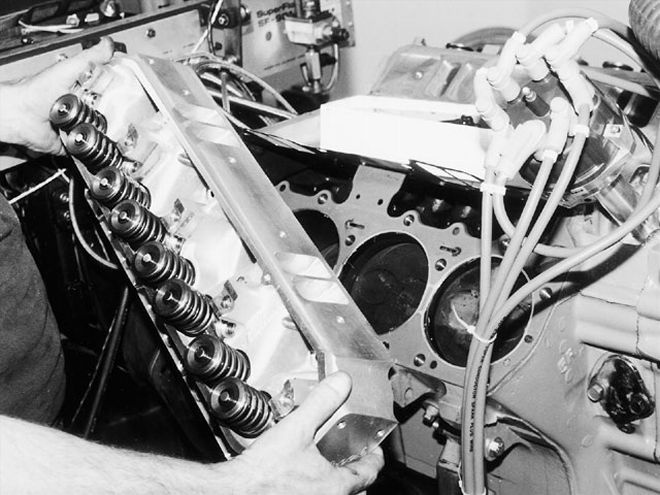

Edelbrock's booty callWe had a street-cammed 440 pumping out power in the high 400s, which is quite good in anyone's book. How would it respond with the Edelbrock heads up top? The swap is quite simple, since these heads are designed to install with minimal hassles. They were designed to take the stock valvetrain, intake manifold, and headers, directly replacing the stock heads without changing anything else. In fact, they were true bolt-ons with the small-hex long-reach spark plugs and headbolts with hardened washers (which we already had) as the only additional parts required. The angled spark-plug position actually provided more clearance to the headers with the tti pipes we tried for fit, and we checked this with both tti's 171/48- and the 2-inch headers.

For our first run with the Edelbrock heads, we went back to the Performer RPM two-plane intake and ran the engine against the dyno for the numbers. Torque spiked up to a massive 557 lbs.-ft. at 4,000 rpm and peak power surged to 538.7 hp at 5,800 rpm. Wow, these things really work! Even down at the bottom of our test range, the torque output was up by nearly 20 lbs.-ft. That number is significant, since at lower rpm we would expect even the stock heads to flow all the air the 440 needs. So where's the added 20 lbs.-ft. down at 3,000 rpm coming from? Part of it must be from increased combustion efficiency, which would stand to reason, since the Edelbrock heads have a superior quench chamber and a more advantageous spark plug position.

Analyzing the information and looking at the airflow required to feed 538 hp, the two-plane intake was now beginning to hold back some power. Though we had the TM-7 single-plane, we didn't hold out much hope that it would be any better than the two-plane RPM, so we decided to run a test with the RPM intake topped by a thick 1-inch open spacer. Sure enough, power went up to 543.5 hp, while torque was actually up slightly all the way to the bottom of the curve, indicating that there were some gains to be had in the manifolding.

For our final configuration, the TM-7 single-plane went on, and as with the stock heads, it fell short of the numbers produced by the Performer RPM, coming in with peak numbers of 552.2 lbs.-ft. and 534.4 hp, plus losing a ton of torque in the lower rpm range. Interestingly, the TM-7 didn't lose as much power on the Edelbrock heads as it had with the stockers. The next logical step would be to try a modern, high-performance race single-plane manifold. Though the pickings at Edelbrock in that area are kind of thin right now, they're currently working on a modern-era Victor single-plane that would fill that gap. We had a look at the computer models of the new manifold at Edelbrock's R&D lab and liked what we saw.

So this is where the scene stands today: almost 550 streetable horsepower from a basic bolt-together 440 using all out-of-the-box parts, whereas cracking just 500 horses in the old days was tough, even with highly modified heads. It's almost too easy. Our engine gained more than 60 hp simply by bolting on a set of as-delivered cylinder heads-60 hp added to the bottom line with no downside to either drivability or reliability. Not only was peak power significantly pumped up, but across-the-board torque was up right from the bottom to the top of the rpm range. There's nothing else that can be done to an engine where you'll find power gains approaching these without giving up noticeably somewhere else.

SUPERFLOW 901 DYNO WESTECH PERFORMANCE GROUP HORSEPOWER RPM 906DP 906SP E-DP E-1” E-SP 3,000 277.6 269.9 288.3 289.5 281.9 3,500 341.2 331.2 358.3 354.3 347.6 4,000 403.4 391.5 424.2 422.5 414.2 4,500 442.1 435.7 471.9 475.5 471.9 5,000 471.1 463.4 507.7 515.3 511.8 5,400 482.9 471.5 531.3 534.0 530.6 5,500 483.0 469.6 534.5 536.2 533.3 5,800 477.4 465.0 538.7 543.5 534.1 5,{{{900}}} 473.9 462.2 536.1 541.6 534.4 6,000 471.1 454.9 536.1 541.2 527.7 TORQUE RPM 906DP 906SP E-DP E-1” E-SP 3,000 485.9 472.4 504.8 506.9 493.6 3,500 512.0 497.0 537.6 531.6 521.7 4,000 529.7 514.1 557.0 554.8 543.9 4,{{{100}}} 528.2 517.6 556.1 556.1 547.3 4,{{{200}}} 526.3 517.2 556.3 558.3 549.7 4,400 519.6 512.1 554.0 556.5 552.2 4,500 516.0 508.6 550.8 555.0 550.8 5,000 494.9 486.8 533.3 541.3 537.6 5,500 461.2 448.5 510.4 512 509.2 6,000 412.4 398.2 469.2 473.8 461.9 906DP: Stock heads; Performer RPM dual-plane intake • 906SP: Stock heads; TM-7 single-plane intake E-DP: Edelbrock heads; Performer RPM intake E-1”: Edelbrock heads; Performer RPM intake with 1-inch spacer E-SP: Edelbrock heads; TM-7 single-plane intake bold values are peakBuilder's Notes-The ComboThe 440 test engine used to run the Edelbrock heads wasn't an expendable dyno mule, but the original numbers-matching engine from my own '71 Charger R/T. Internally, the combo is a mixture of basic, with a touch of exotic. The basics are the factory-forged crank, Six Pack rods, and a set of .030-inch over TRW No. 2355 Six Pack pistons. With the deck milled for -.012-inch piston-to-deck height, the compression ratio computes to 9.8:1 with the heads' 84cc chambers. SpeedPro file-fit moly rings seal the pistons to the bores. The engine's components were weight-matched and the crank dynamically balanced. While balancing, the eccentric external balance weight was omitted from the flywheel side to eliminate the special-balance converter/flywheel hassles, but the eccentric front damper was retained for the OE performance look.

The exotic touch is in the cam and the valvetrain. Here we went with a solid street roller from Competition Cams, because for area under the lift curve, nothing beats a solid roller. This translates into a broader power curve, more power for any given level, with reasonable or idle quality. Street solid rollers aren't catalog grinds for the Mopar engines, so they must be ordered directly from Comp on a custom basis. Specified in this application were lobes No. 4874 on the intake, No. 4875 exhaust; on a 110-degree lobe separation, ground with 4 degrees of advance. Rated duration specs come in at 280-degree intake/ 286-degree exhaust (242/248 degrees at .050 inch), with a gross valve lift of .570/.576 inch. Comp's Pro-Magnum No. 1321 stainless steel rockers were used, a nice setup for the big-blocks, though presently available only in the stock 1.5:1 ratio, and Comp's beautiful Hi-Tech one-piece 31/48-inch race pushrods. Rounding out the valvetrain are a set of Comp No. 929 valvesprings and No. 721 titanium 10-degree retainers. When swapping over to the Edelbrock heads, keep in mind that the keepers (Comp's 10-degree SuperLocks) must be changed from the stock 31/48-inch valve stem size to Edelbrock's 1111/432-inch spec. With the Comp 10-degree retainers, only the locks must be changed, since the retainers are the same for either valve stem size.

Usually we run a 171/48-inch header on street 440s. In previous testing, on a less powerful 440 than this one, going from 131/44-inch primaries to 171/48-inch increased output at both ends of the RPM scale. Following the trend that bigger is better, for this test tti's 2-inch headers were used. Though back-to-back dyno tests weren't conducted versus a 171/48-inch headers, the numbers produced with the larger pipes didn't suggest that low-end suffered from the larger header, and the big pipes likely contributed to top-end horsepoer.-Steve Dulcich