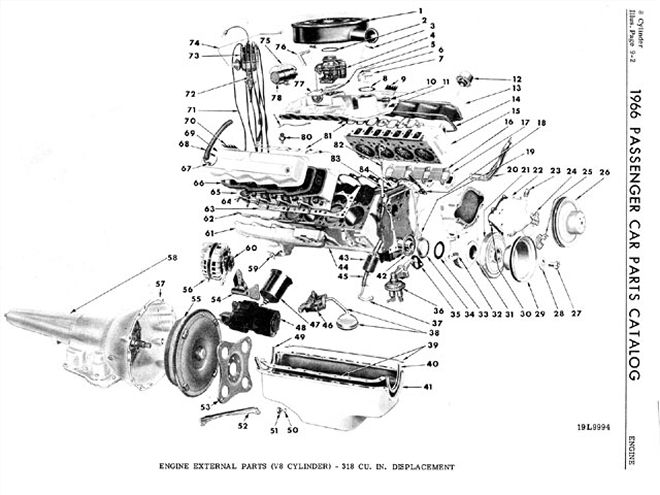

For those of us with Chrysler Corporation products built after 1966, the small-block family consists of engines derived from the "LA" 273 package introduced in 1964. These came in 273-, 318-, 340-, and 360-inch displacements. A majority of the speed parts now available for small-block Mopars fit this package, with the 318 LA engine being the most common and pedestrian of the group. However, for people owning cars from 1955 to 1966, there is another "A" engine, commonly known as the poly-head small-block.

This name came about due to the polyspherical nature of the head design; it's not a wedge design like most other non-Hemi engines. Instead, it used a canted-valve or semi-Hemi layout, much like race engines use today. Unfortunately, since the '60s, the poly engine line has been "dissed" as little more than scrap metal, something to stick behind the garage since it was too heavy to tote away. There were some reasons for that, however. The engine, based on the early Hemi hardware, is a good 70 pounds heavier than the small-block that succeeded it. Unlike the LA engine line's 340, there were few factory performance packages for the poly engine, none after 1962-the year Mopar's styling cues and performance era really began. It didn't help that the largest displacement the engine went to was 354 cid.

Nonetheless, with many still in service, this article will serve as an introduction to the engine line, helping you ascertain the parts that are available, interchangeability, and engine identification. Moreover, if you have the urge to "kick up" your poly a bit, there are some tricks that will let you get more thunder out of it.

The poly engine shown here would normally be discarded for a different mill. However, don't be so quick to toss it overboard. The poly engine line produced between 1956 and 1966 can be built to run hard and look good.

The poly engine shown here would normally be discarded for a different mill. However, don't be so quick to toss it overboard. The poly engine line produced between 1956 and 1966 can be built to run hard and look good.

Engine ID: A Poly Primer

Chrysler's poly-head engine is unmistakably unique from other Mopar engines. It is easily distinguished from the later LA counterparts by its wide stance in the engine bay, looking more like a big-block than a small-block (the distributor location is in the rear, however). The valve cover design differs from the LA motors (273, 318, 360) in that they attach with two bolts in the middle of the valve cover (three bolts for the '56 Plymouth 277-inch poly) rather than the five small screws around the outside of the later LA motors. Some early versions used a unique scalloped valve cover.

With a valve cover removed from the poly motor, the intake valves are on one side of the rocker shaft and the exhaust valves are on the other side; in the later LA motor, the valves are all to one side of the rocker shaft. As a result, the exhaust ports on the poly are evenly spaced, similar to the Hemi design, as can be seen when the exhaust manifold is removed. These poly-head exhaust manifolds run parallel to the heads on each side, like a log, with very little gap between the manifold and the head. Then they exit downward at a sharp angle at the end of the cylinder head-not high-flow by any stretch of the imagination.

As previously stated, there are some variances between the Dodge, Chrysler, and Plymouth poly motors. The earlier Plymouth poly motors have a closed valley cover which is sealed by the intake manifold itself, while the '55-'58 Dodge and Chrysler polys have a valley cover pan under the spider-like runners of the raised intake manifold (we call them air-gap manifolds now, but Mopar had them in the '50s on the poly). The timing-case cover on the earliest Dodge and Chrysler polys are similar to the early Hemi engines, while a different version in both appearance and fit can be found on the Plymouths.

The engine ID is on the front left bank of the block next to the timing-case cover below the cylinder-head face. The first letter and digits may help identify which year poly engine one may have, though the external design of the poly head is self-authenticating. Chart A is a list for basic identification of these powerplants.

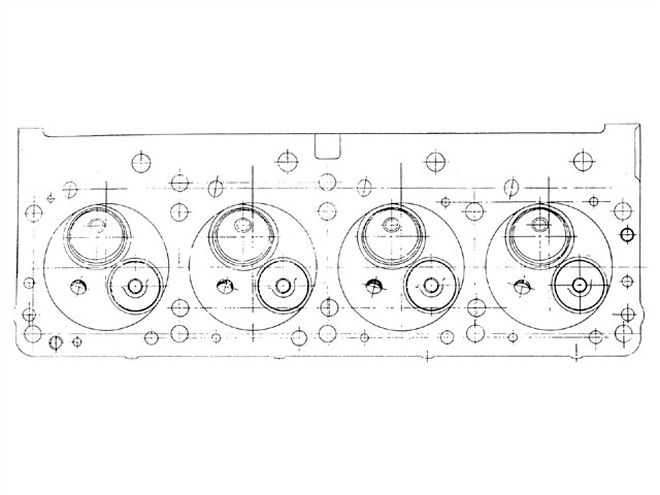

This image from Mopar Performance shows the general combustion chamber layout and valve placement. The intake valve is canted, while the exhaust valve is on a vertical plane.

This image from Mopar Performance shows the general combustion chamber layout and valve placement. The intake valve is canted, while the exhaust valve is on a vertical plane.

Interchangeability: Swapping Poly Hardware

Due to the design similarities, pieces from the early Chrysler 301-, 331-, and 354-inch poly-head engines and Dodge 270-, 315-, and 325-inch poly-head engines can easily be interchanged with early Hemi parts to create a Hemi engine; indeed, these displacements all came in both poly and Hemi trim. This is accomplished with a swap to early-type Hemi heads, pistons, and pushrods. However, since these motors are now uncommon, we'll focus more on the ubiquitous Dodge and Plymouth poly 277-, 301-, and 318-inch engines from the '56-'66 era and their compatibility with the later-style LA motors and parts.

There are literally thousands of these motors still serving their masters faithfully in cities, townships, and 'burgs across our fruited plains, while numerous others sit idle, waiting for their owners to realize their full potential. Counting these mills as "nautical bygones" (yep, boat anchors) is like Captain Ahab spitting on Moby Dick! Their soiled mental reputation not withstanding, durability, horsepower, and torque are easily breathed into these early poly motors using many of the 273, 318, 340, and 360 LA motor go-fast goodies now available. Chart B is a list of common parts you can mix and match with the LA family of engines to refresh or resurrect the poly power in your ride.

A few more facts are in order here. All of the '56-'66 poly motors have the same rear block-face bolt pattern as the later LA motors and can share the same crank. However, only the '62-'66 polys came with the same crankshaft as the 273/318/340 motors, the crank that accepts the popular '62-and-later aluminum case TorqueFlite transmissions. The '56-'61 poly motors use a crank with an extended flange, mainly for use with the old-style, cast-iron case TorqueFlite transmissions, so you may want to use a '62-and-later crank. Note that crankshafts used in automatic transmission-equipped vehicles are not machined for the manual transmission's pilot bushing; you need to machine them if you are swapping in a crash-box. Finally, the large-diameter 360 crank can have the mains ground down to fit a poly 318 block as well as the 273/318/ 340 blocks, creating a stroker engine.

This is only a brief introduction to the poly engine family. A stroker poly engine displacing 400 inches or more is not only possible, but also capable of putting some solid numbers up on the dyno. In a future issue, we will show you how we built such an engine, complete with ported heads. Stay tuned.

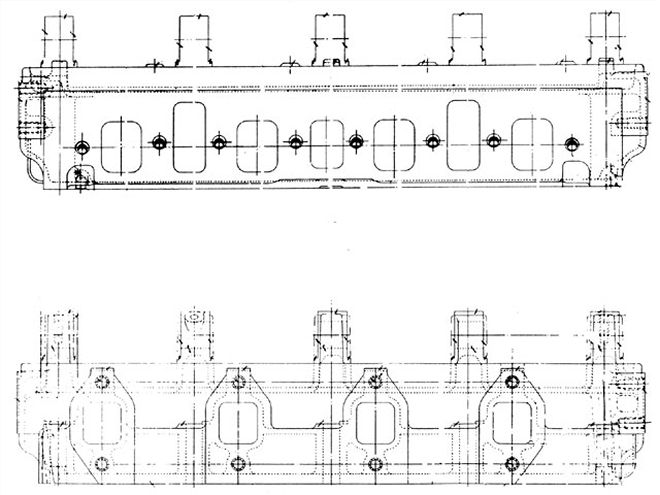

The intake (above) and exhaust (below) of the poly-head layout shows how the port placement is similar to the Hemi engine's design. A good port job can make a world of difference in making the heads breathe.

Chart A{{{Plymouth}}} Poly V8Engine IDCIDYearP272411955P29270*1956P292771956FP29303 Fury1956P31-12771957P31-23011957FP31318 Fury1957 FLP318 Fury1958MP83181959P3183181960R3183181961S3183181962T3183181963V3183181964A3183181965B3183181966

{{{Dodge}}} Poly V8Engine IDCIDYearD552701955D63-12701956D63-23151956D63-3315 (4-bbl)1956KDS3251957KDS325 (4-bbl)1957LP83181958LD2 (L325)3251958DMP83181959P3183181960R3183181961S3183181962T3183181963V3183181964A3183181965B3183181966

{{{Chrysler}}} Poly V8Engine IDCIDYearC67 WE553011955C71 WE563541956C75-1 WE573541957C75-2 LE573541957LC-1L 58W3541958LC-2M 58S3541958

The intake (above) and exhaust (below) of the poly-head layout shows how the port placement is similar to the Hemi engine's design. A good port job can make a world of difference in making the heads breathe.

Chart A{{{Plymouth}}} Poly V8Engine IDCIDYearP272411955P29270*1956P292771956FP29303 Fury1956P31-12771957P31-23011957FP31318 Fury1957 FLP318 Fury1958MP83181959P3183181960R3183181961S3183181962T3183181963V3183181964A3183181965B3183181966

{{{Dodge}}} Poly V8Engine IDCIDYearD552701955D63-12701956D63-23151956D63-3315 (4-bbl)1956KDS3251957KDS325 (4-bbl)1957LP83181958LD2 (L325)3251958DMP83181959P3183181960R3183181961S3183181962T3183181963V3183181964A3183181965B3183181966

{{{Chrysler}}} Poly V8Engine IDCIDYearC67 WE553011955C71 WE563541956C75-1 WE573541957C75-2 LE573541957LC-1L 58W3541958LC-2M 58S3541958

Chart B

273/318/340/360 LA Parts

Interchange With The Polyspherical "A" Motor

Induction Science: Over-The-Counter Speed Parts

For your poly project, performance cams should be ground from new blanks (luckily, these can be purchased from Chris Neilson Cams and Daytona Cams), and cylinder heads can be upgraded with a die grinder (no hot replacements) using the MP Small-Block Engines book blueprints as a guide. Pistons should be custom-tailored for the poly-head design; stan-dard LA pistons will not fit. There are also some intakes that allow you to move more air through the engine if you are ready to dump that two-barrel setup that came stock on your vehicle. The early '56-'62 poly motors had three flavors of factory-installed induction hardware: the two-barrel grocery-getter intake, the four-barrel sure-to-smoke-you-now intake, and the now-coveted dual-quad let's-bet-pink-slips intake. When you wanted to get serious, the OEM cast-iron four-barrel and dual-quad intakes were the E-ticket rides of their day; after 1962, poly intakes were all grocery-getter versions.

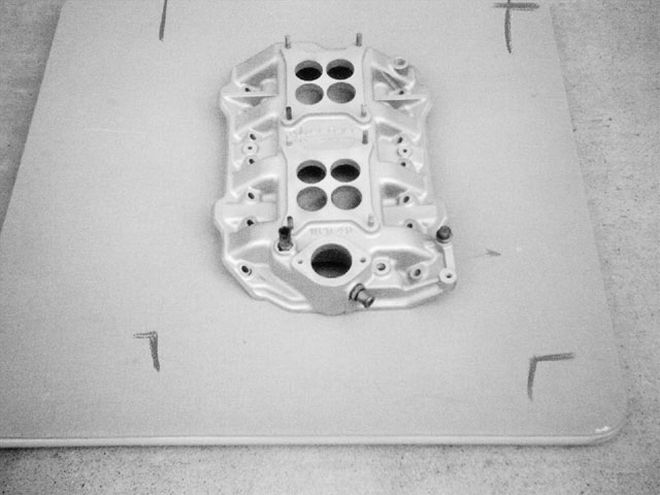

Here are a pair of induction setups for the poly engine. One mounts a pair of Carter WCFB carbs, while the other hosts a brace of Strombergs. For performance enthusiasts, there are still new aluminum intakes available from Weiand.

Here are a pair of induction setups for the poly engine. One mounts a pair of Carter WCFB carbs, while the other hosts a brace of Strombergs. For performance enthusiasts, there are still new aluminum intakes available from Weiand.

The factory four-barrel intake was available through 1962 on the poly 318, while the dual-quad version had a shorter run through 1958. These factory intakes fit all '56-'66 Poly 318 engines, though note that the earliest '56-'57 model intakes used the WCFB (Will Carter Four-Barrel) carburetors with their small-pattern mounting flange. Today, these carbs are less plentiful and a bit pricey, especially for the numbers-matching crowd. A better bet is to find a version which mounts the popular Carter AFB (Aluminum Four-Barrel) carbs, the '58-and-later intakes.

There are also some rare and ultracool street induction setups still passing from hot-rodder to hot-rodder if you know where to look. At one time, Edelbrock built a dual-plane, three-deuce aluminum intake (PN P600) that used Stromberg and early Holley carbs. Edelbrock also made a limited number of finned aluminum valve covers to complement its triple-threat intake. Weiand produced an aluminum dual-quad intake (PN WPD 4 D) for the weight-watchers crowd as well as the single-plane four-barrel (PN 7503) and the dual-plane four-barrel intakes (PN 7508). Offenhauser was reputed to have been in the game as well with a single four-barrel aluminum intake.

If scouring swap meets and garage sales for these OEM and rare aftermarket intakes and carbs don't thrill you, take heart, because new Weiand aluminum four-barrel intakes (PN 7503) are readily available for the Poly 318. Moreover, Edelbrock, through its Carter arm, is still serving up the popular 500-cfm carb for dual-quad applications and the 600-cfm and larger carbs on single four intakes. Need to hook it up? Slick, high-tech progressive linkage waits on Edelbrock's shelf for the dual-quad enthusiast (PN 7094). Still want more? Dick Landy Industries even offers a Holley Powercharger 174 mini-Roots supercharger complete with the blower, the intake manifold, and all the necessary hardware for the Poly motor.

Of course, what goes in must come out, and the factory exhaust manifolds could really use some upgrading. Three options exist for this. The easiest way is to buy a set of headers from Spitfire's Harold Johnson, who has them available for various applications. The second is to have a shop fabricate a set of custom tubes for you. The third, and most adventurous, is to buy a Mopar poly-header flange and tubing kit, and do it yourself. Regardless, headers and a good exhaust system go a long way in making more power with your poly. Boat anchor? Imagine lifting the hood on your outwardly docile, hubcap-clad, Coronet or Belvedere to reveal that Weiand/AFB or dual-quad poly-head engine lurking beneath. Before the Brand-X competition cries foul, just let them know it's not a transplanted big-block torque monster that just blew their doors off, but a small-block poly 318 that is indeed native to those fenderwells. Ahhh, the victory is sweeter when you look like a sleeper but can smoke 'em at will! The poly motor in proper tune and attire can indeed run both hard and fast.-GP