When we last pulled our street 360 combo off of the dyno, our astoundingly stock 360 (lifted from a wrecking yard '79 Cordoba) pulled down an impressive 390 horsepower at 5400 rpm, and torqued-up to the tune of 404 lbs/ft. at 4600 rpm. The combo was bread-and-butter plain, fitted with a Comp Cams 280 degree Magnum hydraulic cam, 10:1 TRW Hypereutectic pistons, an Edelbrock Torker II manifold, and Hooker 151/48-inch street headers. Inside the stock .030-over '79 block were stock rods, stock cast iron crank secured with stock bolts, and a stock windage tray. On top was the original '79 Cordoba smog heads (which we showed in detail how to effectively port) dressed with the stock rockers on the stock shafts, with stock pushrods. Up top, a stock Chrysler Thermoquad mixed the air and fuel, while a stock distributor fired the mixture through a regular stock-type Chrysler electronic ignition.

In the last installment of our "Double Take 360" we made over 390 horsepower and 404.8 lb/ft of torque. We were gunning for more this time, and decided to open the bottom end for some minor durability mods.

In the last installment of our "Double Take 360" we made over 390 horsepower and 404.8 lb/ft of torque. We were gunning for more this time, and decided to open the bottom end for some minor durability mods.

Plain as it all was, with our highly effective modified smog heads working with a well matched cam and induction, this mill delivered more power than many commonly sold, more exotic engine combos. How about ZZ4 or LT 4 Chevy 350 crates with Aluminum heads and roller cams, boasting 355 and 360 horsepower respectively? The Ford GT-40 A351 bracket race motor and its 385 horsepower with 16 degrees more intake duration and 26 degrees more exhaust, not to mention the aluminum leads? Have we broken any illusions here?

Yeah, we figured our street 360 was making pretty good power already, but our intention from the beginning was to take the same basic combo up a few notches, while retaining a streetable set up. We decided to keep the rest of our combination as it was, and step up in the area of the cam and valvetrain. The only question was what approach to take in making the change. The most obvious route would be to simply go to a bigger hydraulic cam. Our 280-degree Comp grind was a full 10 degrees shorter than the cam found in the Mopar Performance 380 horsepower crate engine. Going up to the Comp 292 Magnum hydraulic cam would no doubt add to our already strong horsepower numbers, but for true street use the trade-off in drivability and idle quality would be noticeable. The fact is that the 280-degree Comp Magnum is just about the ideal hot-street/strip hydraulic cam if you really want to live with it on a daily basis. We just weren't prepared to give that up for a few more top end ponies.

Just the bare essentials were going to be added for peace of mind in the form of a Milodon main stud kit to replace the original junkyard bolts. Our stock windage tray relies on the factory main cap bolts for mounting, so we made the swap to a Milodon tray designed to work with their #81186 stud kit.

Just the bare essentials were going to be added for peace of mind in the form of a Milodon main stud kit to replace the original junkyard bolts. Our stock windage tray relies on the factory main cap bolts for mounting, so we made the swap to a Milodon tray designed to work with their #81186 stud kit.

Solid Performance

We figured if we were going to swap out our current cam in the quest for more power, we'd have to go with something trick to see meaningful gains in power without a large trade-off in drivability. What we wanted was the high rpm stability of solid lifters, a relatively short "seat," or overall duration, but lobes that open the valves at a truly radical rate. We found what we were looking for in the lobe specs pages of the Competition Cams catalog. The Comp Tight Lash solid profiles are no-compromise, full-race endurance engine lobes designed for maximum valve acceleration off the seat. The most aggressive of these are listed as .875-inch minimum lifter diameter profiles. Speaking to Comp's chief cam designer, we were told these lobes were pushing it to the limit with a .875-inch diameter lifter (everything had better line up perfectly), but are an ideal match with a Mopar .904-inch tappet.

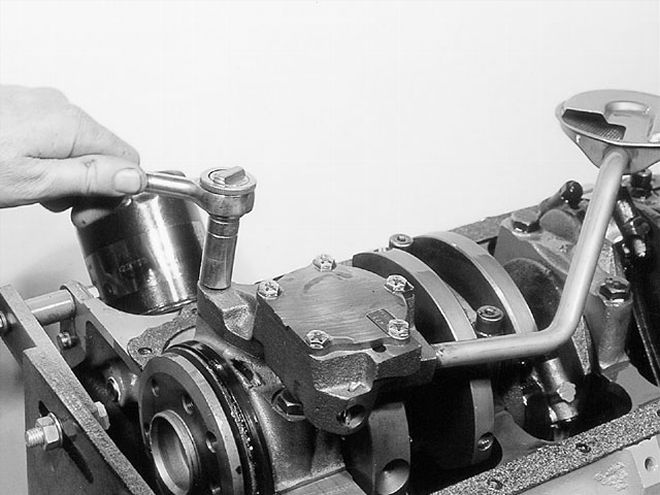

To replace the tray, the oil pump had to come out.

To replace the tray, the oil pump had to come out.

For our application, we chose the FL272 lobe for the intake, giving 272-degree rated duration, 243-degree duration at .050-inch, and .542-inch lift. On the exhaust we selected lobe FL276, with 276-degree rated duration, 247-degree duration at .050-inch, and .549-inch lift. Note the short rated duration timing of 272 and 276 degrees. These are short duration, short flat-track lobes, designed for torque out of turns in roundy-round racing. But look at the duration at the .050-inch number in comparison. At 243 and 247 degrees, these lobes have .050-inch numbers comparable to "street" solids of 295 degrees duration, and reach lifts common to cams with 300+ degrees of duration. In fact, the rate of acceleration is more intense than most hydraulic rollers and solid street rollers on the market, and approaches that of a race roller. The final effect is maximum area under the valve opening curve, contained within a manageably short overall duration, all wrapped in a high winding, cost effective solid lifter package. With our lobe selection made, we decided upon having the cam ground on 108-degree lobe centers which, we felt, would work best in our now serious street 360.

The Milodon studs are turned into the bolt holes by locking two nuts and winding them in until snugly seated (Milodon calls for 10 lb/ft., but we adjusted by feel). They also recommend the block's threads be cleaned with a bottoming tap, which we had already done during the initial block prep. Note that a stud cannot be used in the left rear main location (arrow) since there is no clearance for a stud between the cap and oil pump. We just retained the stock bolt in this position.

The Milodon studs are turned into the bolt holes by locking two nuts and winding them in until snugly seated (Milodon calls for 10 lb/ft., but we adjusted by feel). They also recommend the block's threads be cleaned with a bottoming tap, which we had already done during the initial block prep. Note that a stud cannot be used in the left rear main location (arrow) since there is no clearance for a stud between the cap and oil pump. We just retained the stock bolt in this position.

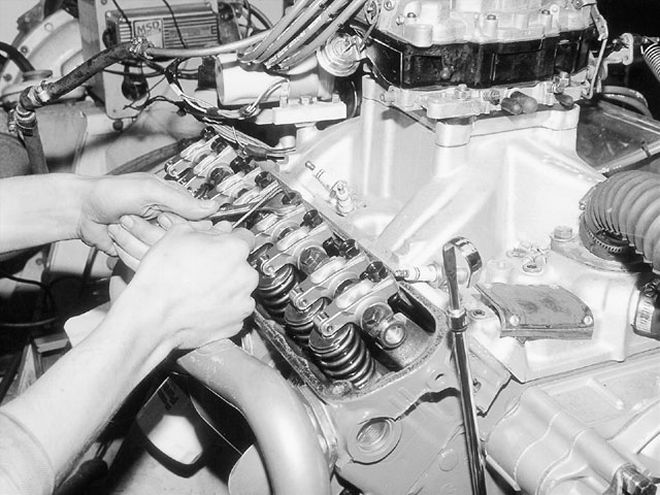

Since we were making the change to solids (and a fairly high lift solid at that), we would need to make some changes to our valvetrain. The stock stamped-steel rockers have no provision for adjustment of lash, which we would now need. Also, since the cam is a fast acting profile, a strong ridged rocker would be required. Finally, with the higher spring loads and greater lift, the added side loading would place a greater strain on the valve guides. To take care of all these issues in one hit, we opted for Comp Cams' Shaft Mounted Magnum roller tipped rockers, kit #1420-16. The strength issue is handled through Comp's use of investment cast 8620 chrome-moly heat-treated steel-virtually bulletproof. These rockers feature roller tips at the valve, which drastically reduce the side loading, and thus guide wear, in applications where higher lifts and spring pressure will compromise guide durability in street duty.

Along with the rockers, solid lifter pushrods are also required. We ordered a set of Comp Magnum pushrods, #7692-16. Not the company's most exotic or expensive offering, but made of C1020 high carbon steel .080-inch thick, they are more than good enough to do the job in our application. Unlike the stock solid pushrods, the Comp 51/416-inch diameter replacements are tubular, giving an excellent weight-to-stiffness ratio, and relieving a significant amount of valvetrain inertia for high rpm stability.

The last item on our valvetrain list was a set of valve springs capable of handling the increased loads, and our anticipated increased rpm with the solid lifter cam. Normally with this cam a dual valve spring would be used, but our heads weren't machined for them, so a stiff single spring was required. We used Edelbrock #5767 springs-a single spring with damper-which we installed at a 1.75-inch installed height. We kept the stock steel Chrysler retainers and PAW locks that we used before.

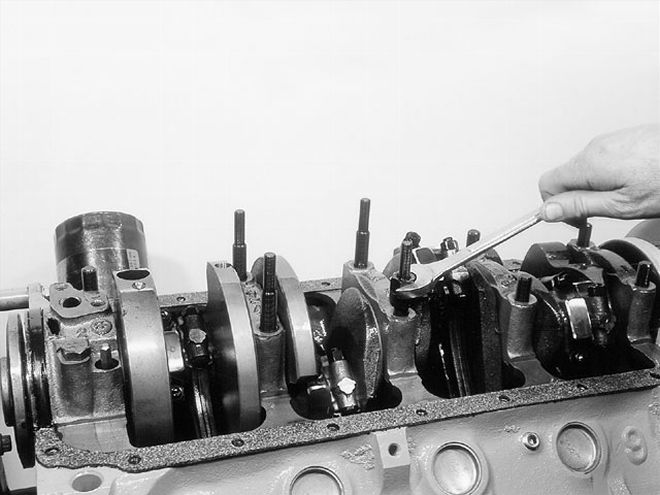

The Milodon stud kit comes with four special studs to receive the Milodon windage tray, which mounts the tray between pairs of nuts at the specified height. Set the nuts face down at the height spec called for in the Milodon instructions.

The Milodon stud kit comes with four special studs to receive the Milodon windage tray, which mounts the tray between pairs of nuts at the specified height. Set the nuts face down at the height spec called for in the Milodon instructions.

Beefing The Bottom

With our cam and valvetrain figured out, we expected the 360 to be able to pull higher revs and make power. In our tests with the hydraulic Comp cam, we pulled the engine to as high as 6400 rpm with the stock cast crank held in place with the used stock junkyard bolts. Everything held firm, and a subsequent post-dyno bearing inspection confirmed that all was well. Yet, with more revs on the horizon, we thought we'd take a few beef-up steps in the bottom end as insurance. No, a billet steel crank was not part of the budget, but we figured the added clamping force of a set of main studs wouldn't hurt. We tapped Milodon for their small-block Chrysler main stud kit, part #81186. These are premium grade race studs manufactured from heat-treated aircraft quality 8740 chrome-moly steel with rolled threads for a tensile strength of 190,000 psi. That's a serious step up from our junkyard bolts.

The one advantage of our junkyard bolts was that they were specifically designed to hold the factory windage tray. Rather than try to adapt our stock tray to the Milodon studs, we went with Milodon's #32230 tray. The #81186 stud kit is a special set for use with the Milodon tray (#81185 is the regular non-tray Milodon stud kit). The final addition to the bottom end was a new elastomer SFI-approved crank damper from Probe.

Time to 'fess up.

Our stock junkyard damper showed some wobble in our last dyno session, and rather than get greasy again by pulling another one from the boneyard, we went with the good stuff this time. The Probe #ROM-0218-CW damper meets the rigorous SFI standards required in racing by most sanctioning bodies, and is already balanced for the externally balanced 360. Just as important to us, the Probe damper is dimensionally correct as far as spacing is concerned, meaning that the stock pulleys will line up.

Back At The Dyno

We returned to the Clayton dyno at Specialized Motor Service with the bottom end changes made to the 360, but with the same Comp 280 Magnum cam and stock valvetrain as in our last test. We wanted to confirm the baseline established in our previous test session to ensure that the engine was still performing. The changes at this point included the Milodon main stud kit, the Milodon tray replacing the stock unit, and the Probe damper. Another change was to lean the secondaries in the Thermoquad carb from the .144-inch jets used last time to .137 jets-a change we wanted to try earlier, but we ran out of time. We were hoping to at least equal our earlier numbers but as it turned out our engine was significantly stronger: 401 horsepower at 5400 rpm (up from 390.3 horsepower at 5400 rpm), and 420.2 ft. lbs. of torque at 4700 rpm (up from 404.8 ft. lbs. at 4600 rpm). That's 10.7 horsepower and 15.4 ft. lbs. of torque more than our previous test with basically the same combo. Past the peak, our 360 hung on at high revs, delivering numbers which belied the cam specs, holding over 390 horsepower at 6000 rpm, and still pulling strong to the end of our pull at 6300 rpm.

Since there were several changes made to our test mule, it's difficult to pin the gain on a specific item, but in truth we had only made mods intended to enhance durability. We have heard of dampers making a horsepower increase, and perhaps the wobble in our junkyard piece was hurting our earlier numbers. On the other hand, the engine was running rich up top, and the jet size reduction could have accounted for the bulk of the gain. The bottom line is that we had a 360 with a sweet street cam in it, smog heads, et al, pulling down over 400 horsepower and making big-block torque.

Cammin' Up

With numbers like these, we were almost reluctant to rip into the engine for a cam change. Still, we thought long and hard as we derived the specs for our custom ground Comp solid lifter cam, and now it was time to put theory to the test.

Overall, the rated duration of the solid cam at 272 intake and 276 exhaust was shorter than that of the hydraulic, but man would it move the valve fast and far when it hit! Make no mistake-because of the way solid lifter cams are rated, the 272-degree rated duration figure is much shorter than the actual duration seen at the valve seat. The valve would see better than 280 degrees of timing (we measured 284), so, overall, the seat timing was close to our 280 Comp hydraulic, but the intensity of this race solid is in another league. The solid was ground on 108-degree lobe centers, two degrees tighter than the street hydraulics' 110. That added to the overlap, and hence "caminess," but sharpened the torque peak.

If you want to boil it down, we went to a radical solid lifter race profile in a duration and lobe separation angle which would keep the overlap in a range where the beast would be tame enough for street use. If we were building a drag engine with ultimate horsepower as the goal, we could have gone 20 or 30 degrees longer in duration, lost all of the drivability and low- to mid-range torque, and seriously surpassed the rpm capabilities of our stock cast crank bottom end. We wanted it all with this cam. The question was, would it deliver?

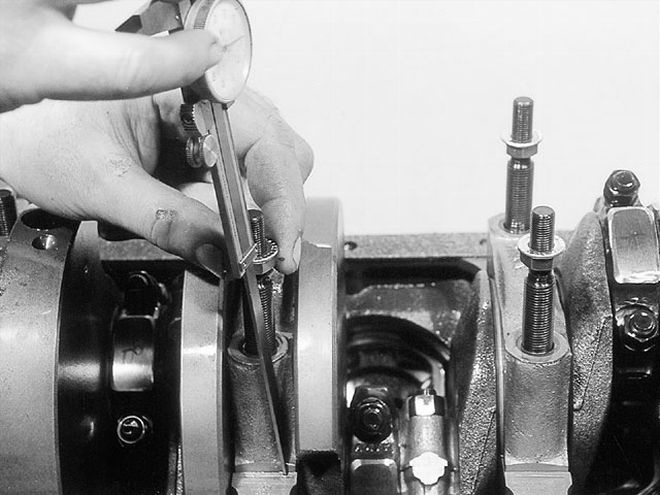

We tore down the engine on the dyno, and the new Comp stick was degreed-in straight up at 108 degrees. The solid lifters were lubed and slid in place of the hydraulic units. After checking piston-to-valve clearance (minimum .100-.120-inch intake; .120-.140-inch exhaust), we found the valves cleared with ease. Next, the valve springs were swapped, with the installed height checked and set to 1.75-inch. The springs were checked for adequate coil bind clearance (minimum of .100-inch). Finally, the lash on the Comp rockers was set to the recommended .018-inch intake; .020-inch exhaust (see: Valve Lash Setting; Chart 2). With our valvetrain we noted that the geometry would have been improved with lashcaps or slightly longer pushrods. Unfortunately, the short tips on the standard Chrysler length valves wouldn't allow lashcaps to fit without the bottom of the caps resting on the keepers-a sure way to have the valvetrain disassemble itself at high rpm. A set of Comp 10-degree retainers and Comp Super Locks with a lashcap recess would have been ideal, providing the required lashcap clearance, but we were well and good enough to run. The valve covers were bolted on and we were ready to turn.

We fired the engine and brought it to 2500 rpm for 15 minutes in order to break in the cam. With no other changes, the Comp solid cam belted out 430.2 horsepower at 6000 rpm, and 412.2 lbs/ft of torque at 4900 rpm. Peak torque was down just 8 lbs/ft at a 100 rpm higher peak, but peak horsepower was up by nearly 30 horsepower, at a 600 rpm higher peak. Overall, at the lower to mid-range end, the solid gave up a little to the street hydraulic, but at the top end, the pulling power was unreal. Even 600 rpm past peak, at 6600 rpm, the solid was still dishing out 426 horsepower. With the hydraulic we had dropped to 376.5 horsepower and declined to 6300 rpm. We limited our tests to 6700 rpm, with the engine still pulling strong. With this cam combo, the top end output just wouldn't quit. We made WOT full load pulls to as low as 2400 rpm with no sign of the engine wanting to fall over, and made 335 lbs/ft of torque. The idle quality was somewhat rougher than with the hydraulic, but was steady at 800 rpm with seven inches of vacuum. Not stock-smooth by any means, but definitely driveable.

Dyno TestHorsepowerTorqueRPMTest 1Test 2Test 3RPMTest 1Test 2Test 32600172.7N/A166.12600348.9N/A335.62800190.6196.6183.92800357.7365.8245.13000204.3207.51973000357.7363.33453200190.1226216.23200359.6370.7354.93400237.6242.4235.33400367374.5363.53600258.3267.7253.13600376.8390.6369.33800281.4281.8274.93800388.9389.4379.9{{{4000}}}299.6310.1297.14000393.5407.23904200319.1313.8314.44200399.1392.33934400320.8329.4328.54400383.8393.13924600354.5352.73524600404.8402.7401.64800359.5379.4375.44700397.2420.2408.4{{{5000}}}377.4392.3389.44800393.4415.2410.75200378.8396.5401.64900399.8410.6412.25400390.3401411.75000396.4412409.15600384399.14205200382.6400.4{{{405}}}.75800387392.3426.55400379.5390400.5{{{6000}}}369.2391.8430.25600360.2374.33946200370.2377423.35800350.5355.3386.1Std. Corrected to 29.92-inch dry air @ 60 degrees (F) Clayton dyno; DEPAC electronics

Bold Values Are Peak

Test 1: From Mopar Muscle, June 2000; Comp 280 Magnum hydraulic cam; stock valvetrain.

Test 2: As above, with Milodon stud kit and tray; Probe damper; re-jet ThermoQuad secondary to .137-inch; Comp 280 Magnum hydraulic cam; stock valvetrain.

Test 3: As above, with custom Comp solid lifter cam lobes #7131/intake, #7132/exhaust on 108-degree lobe seperation, installed at 108; Comp Magnum roller rockers; Comp pushrods; Edelbrock springs.

With the cam installed and the valve gear all in place and checked, we ran the engine at 2000-2500 rpm for 15 minutes to break in the cam, then reset the lash at Competition Cams' recommended .018-inch intake/.020-inch exhaust. Next came dyno pull time, and it was all glory, with a humble '79 Cordoba 360 smog engine and its original heads pumping out a streetable 430 horsepower, and still hanging on at 6700-plus rpm.

Engine position for setting valve lashCrank PositionIntakeExhaust#1 TDC FIRING #2 & #7#4 & #8•Rotate Crank 180 Degrees•BDC#1 & #8#3 & #6•Rotate Crank 180 Degrees•TDC#3 & #4#5 & #7•Rotate Crank 180 Degrees•BDC#5 & #6#1 & #2

With the cam installed and the valve gear all in place and checked, we ran the engine at 2000-2500 rpm for 15 minutes to break in the cam, then reset the lash at Competition Cams' recommended .018-inch intake/.020-inch exhaust. Next came dyno pull time, and it was all glory, with a humble '79 Cordoba 360 smog engine and its original heads pumping out a streetable 430 horsepower, and still hanging on at 6700-plus rpm.

Engine position for setting valve lashCrank PositionIntakeExhaust#1 TDC FIRING #2 & #7#4 & #8•Rotate Crank 180 Degrees•BDC#1 & #8#3 & #6•Rotate Crank 180 Degrees•TDC#3 & #4#5 & #7•Rotate Crank 180 Degrees•BDC#5 & #6#1 & #2

Note: The above method is for shorter duration cams; for long duration cams (290+ degree @ .050-inch lift), use the Mopar Performance position method.