Do big 500 cubic inch mountain motors, or 400 cubic inch small blocks, make more horsepower than the foundational engines of their beginnings? Not necessarily. As a matter of fact, raw horsepower is not always the answer for lightning quick acceleration. In most street or bracket applications, pure gut-wrenching torque is tremendously more important than outright horsepower for 99 percent of us. And torque is the exact reason for building a long arm engine.

Why build a stroker motor? It's an engine's torque, multiplied by gear ratios, that slingshot a vehicle from a dead stop. The advantages of more torque converter stall speed helps both street and strip vehicles. On the street, low-speed torque makes an engine tractable and easy to live with. A few hundred rpm more converter flash from the long arm engine sure works well with those standard rearend gears-whether for the street or strip. As any experienced racer will attest, a drag race is won at the starting line. The added low-end torque of a stroker slips an existing converter to a greater degree so more stall speed occurs and a vehicle will launch harder. A few hundred rpm more converter slip trackside will show up in lower elapsed time.

Straight-line racing and street performance aren't the only beneficiaries of low rpm engine torque. Short track, half-mile, and dirt racers also reap benefits from bottom-end power when coming out of slow speed turns. Low rpm power is torque in action. Additionally, power at the bottom of the rpm range means less wear on the engine and greater longevity.

If we think back to the musclecar era, the one thing Mopar engines were noted for was thundering amounts of torque. When you think of those high-winding late '60s/early '70s 302 buzz bombs offered by brands X and Y, do you think of torque? Hardly! Those engines needed high numerical rear gears, close ratio transmissions, and stratospheric rpm to propel away from a starting line. The lack of torque was the reason Z28s came standard with 3.73 gears (up to 4.88 factory available), not to mention the fact that 302 Z28s and Boss 302s couldn't be had with an automatic trans. Without the deep gears, those cars would have needed Jet Assist Take-Off bottles to get out of their own way. By comparison, the standard gear for most high-performance Chrysler engines (big or small blocks) was a 3.23. The 727 was both ubiquitous and legendary among Mopar followers. It was available with anything Mopar had to offer, street or race.

Of all the American V-8s ever made, the Chrysler engine is unquestionably the best nominee for the long arm treatment. Those outstanding OEM rod ratios, voluminous crankcases, and generous crank center-to-deck dimensions provide Mopar engines with an unfair advantage over the competition. Let's run down a list of the what-nots and where-fors that'll help guide potential long arm Mopar engine builders with the how-tos.

The Connecting Rod

The connecting rod is at its greatest angle when it swings up from bottom dead center to the halfway point of the stroke (90 degrees from bottom dead center). The angle, and/or what engine builders refer to as the rod ratio, gives a general idea of how much pre-load is placed on the center of the cylinder wall (the weakest part of the cylinders) and the piston skirts. As the rod tilts toward generating its lowest numerical ratio, frictional drag increases in the engine. More friction equals less potential horsepower, especially at higher rpm. Keep the rod as parallel to the bore as possible (higher numerical ratio) and you'll build a better mouse (or rat) trap. Pun intended.

To calculate the rod ratio, simply divide the center-to-center length of the rod by the engine's stroke.

Academically, engineers consider rod ratios in the 1.70s and 1.80s ideal for the internal combustion engine. At a time when the competition's engines were being built with crank pounding/block-busting rod ratios in the 1.50 to 1.60 area, Chrysler engines were rolling out of the door with torque generating ratios, typically in the 1.80 range. These were rod ratios Chevy and Ford owners would die for. If you're considering building a Mopar stroker motor, chances are you'll still maintain a rod ratio better than the other guys are starting with!

Another advantage to having a good rod ratio deals with camshafting the engine. In a nutshell, it goes like this: Vacuum is the source of all things good for performance (or gas mileage). Longer duration cams lessen the low-speed vacuum signal to the carb, while engines with shorter duration cams raise vacuum signals. The better rod ratio, the longer the piston will dwell at TDC to complete the combustion cycle. Or said in application terms, lower numerical ratios like those of Fords and Chevys need longer duration cams to get the most out of the combustion cycle. However, those longer duration cams weaken bottom-end torque. For the other guys, improving their rod ratio means they'll be spending big bucks on expensive, longer center-to-center rods. Mopar builders won't need to make such investments.

As for the rods themselves, use the following tips. Be absolutely sure you're starting with a good set from the start. Especially if we're talking about used rods. Why? Simple. When rod angle increases, the rods have more pre-load and function in a more stressed environment. Start with a questionable rod, and you'll build a questionable engine. It is extremely important that your shop check for straightness. Anything bent is going to get worse in a stroker. Also, have them Magnafluxed, just to see if any cracks appear along the beams or broaching areas. No problems so far? Then have new performance bolts like ARP's 8740s, or super-duty ARP2000, installed and the big ends reconditioned. If you go all wild and crazy and polish the beams, Zyglow, X-Ray, and stress relieve the rods (new or used), you'll just about have as much invested as a new set of Eagle rods (which come with all the aforementioned goodies). New Chrysler OE replacement performance rods will actually cost you more than a set of Eagles! The Eagle H-Beams also offer another distinct advantage for stroker Mopars-clearance. Their short little capscrew isn't as long as the traditional rod bolt piece. This means you won't run into clearance problems at the rod bolt/cam interference area, or have to deep-cut the bottom of the cylinder wall as much (See "The Chrysler Block and Crankcase Prep" (below) for details.) as an OE-rodded engine. They are also a bit lighter, aiding balancing costs and offering rev-ability.

The Chrysler Block And Crankcase PrepLong rods need plenty of room to negotiate while inside the crankcase, which the Chrysler block has in abundance. Mopar street and mild bracket strokers do not need to worry as much about things like a rod bolt whacking out a cam lobe, deep notching in the lower cylinder wall to insure rod to block clearances, or rod-to-pan rail interference problems. (See the chart, "Critical Mopar Engine Dimensions," on page 55.)

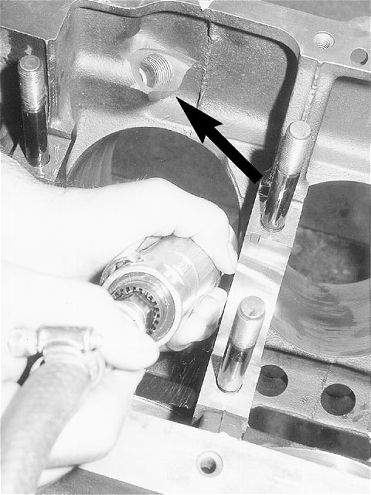

Use a die grinder or an electric drill to grind a rod bolt clearance notch into the bottom of the cylinder. This is an easy job to do at home before you send everything off to the shop. Start out by degreasing the inside of the crankcase with a suitable cleaner. Clean off your old bearings with brake or carb cleaner and reinstall the crankshaft (you don't need the stroker crank to do this) in the saddles. Get two rods with the pistons still hung on them (no rings necessary) and clean them, too. Obtain machinist dye or marking material. Liberally paint your marking material around the lower cylinder bore. Now, install both piston/rod assemblies on the same rod journal. You'll only need to snug the rod bolts down, then rotate the crank and rotating assemblies, eyeing where the bolts come closest to the cylinder bore. Scribe that area out. Repeat this procedure for each cylinder. Now, pull out the used crank, rods, and pistons and set them aside. It's time to start grinding. Notch out an area almost an inch across the lower cylinder, about a half inch deep. If you're using stock rods with your big or small block, this amount of clearance notching is all you'll need. Just be sure that when you mock up your engine with new parts, you double check this critical area. If you need to do some minor grinding, put small magnets where you're re-grinding and wash the block out when you're done. If you're building up a big block (RB or B), you'll also have to do some clearance massaging around the oil pick-up boss. A-Engine modifiers need not worry about this area.

Your stock Chrysler main caps are strong units from the factory. Especially for engines that won't see much more than 5,500 rpm, or engines that aren't expected to make over 525hp. Main studs, like ARP offers, are recommended though, just to maintain bottom-end integrity and keep the caps from dancing on the mating surfaces. If you're building up a serious motor, making more than 525hp, consult Pro Gram Engineering for the ultimate in two-bolt A or B-Engine caps. Pro Gram also offers B/RB Hemi-like four-bolt conversion caps for big blocks and four-bolt conversions for the small block. Use studs with these billet steel caps and fear nothing.

Though all Chrysler blocks are good for stroking, some blocks are better candidates than others. Big blocks made in the early- to late-'70s have outside reinforcement ribs that make the blocks slightly stiffer than non-ribbed blocks of the '60s. They're a good foundation for any sort of high-performance build-ups. However, mid- to late-'70s B/RB's should not be overbored past .030 inch. Early 360s can be bored more than later versions because they basically used 340 block castings (4.04 inch standard bore). This applies to 360s with casting dates that run from 1970 to 1972. Hemi blocks cast after car production ceased in 1971 are also tolerant of big-time overbores. Any block, though, 360, 440, Hemi, etc., should be sonic-tested if you plan to bore the holes more than .030 inch. Do so because it's the only sure way to look at core shift from cylinder-to-cylinder and bank-to-bank. Always leave at least .100-inch of cylinder wall in the thinnest part of the casting just to be safe. Anything less than that could crack a cylinder at the weak point if overheated. Besides, thin cylinder walls are less rigid than thick ones. Guess which one contains pressure best and which doesn't.

Long Arm Crankshafts, and Bearings, Too! Basically you have two options, custom-forged and welded-up factory cranks. There are advantages and disadvantages to both. Before we jump into that, let's back up a bit and look at the OEM Chrysler-forged crank.

Mopar steel cranks came out of the factory with a slightly better material than what other manufacturers offered in the '60s and early '70s. However, Chrysler-forged cranks came with less-desirable rolled journals. There were a few exceptions to this rule. When Chrysler got really serious, they had the cranks ground with durable full tangent-radiused journals. Examples are the NASCAR Hemis that came with super strong Kellogg crankshafts and the 318-3 big-truck crank. Today, these are still premium pieces if they are in standard specs and have no cracks.

Chrysler added another novelty to crankshafting, at least for Hemis-a surface prep called Nitride Hardening. This treatment left the journals super-hardened to a depth of less than a piece of paper. Should a bearing fail, there was now a better chance the bearing would take the beating as opposed to the crank. The drawback to these cranks was the Tri-Metal bearings which required frequent oil changes. If the oil wasn't changed frequently, grit built up in the oil and scored the bearings and crank journals in a big way. In a worse case scenario, infrequent oil changes would lead to a spun bearing, then the crank would have to be re-ground. Unfortunately, regrinding goes deeper than the thin depth surface hardening, wiping out the Nitriding. So you're back to square one.

Clevite (a.k.a. Michigan 77) rectified the situation with a better bearing than the Tri-Metal of the '60s. It was called the Micro Babbit bearing and could be used with both hardened and non-hardened cranks. Hemi owners rejoiced with its introduction because now grit would imbed into the thin babbit-lining surface instead of tearing up the hard tri-metallic bearing surface. Now, infrequent oil changes would be less life threatening.

On a side note, where did all the Hemi cranks go back in the '60s and early '70s? No doubt some owners tossed them out because they thought the cranks were junk if regrinding was in store. Sadly though, did you know that the Hemi (or RB Chrysler) crank is easily reground to fit a big block Chevy? Yup! Just regrind (or offset grind) the journals to Chevrolet sizes, trim the snout shorter to fit a Chev balancer, and grind the rear main journal to fit the Chevy's rear thrust bearing. Now your Bow Tie could race with a stronger crank, and adapting a stronger trans, manual or automatic, was an easier job. Like killing two birds with one stone. Many, many Gas, Altered, Modified Production, and early Funny Car Chevy owners did this modification. Ugh!

Another note: Bearings not only differ in composition but in edge shape. Bearings designed for factory-rolled ends have little taper on the outer ends of the riding surface. Installing them on a radiused journal crank will either bind up the rotating assembly, or cause a major oiling problem. Clevite/Michigan 77 stocks bearings for both occasions. Tri-Metal bearings that end with an "H" properly fit cranks with radiused journals while bearings that end with numbers should only be installed on cranks with OE type rolled journal ends. An "M" at the end of the part number stands for Micro Babbit. "M" bearings are narrower than the standard, or Tri-Metal bearings, and will fit cranks with either journal end.

Okay, with the crank and bearing prep out of the way, now let's get to the facts. If you want to be large and in charge, one way to get to that goal is to save your pennies and opt for the custom steel-forged cranks. Mopar Performance, TICO, Crower, and a host of others offer stroker cranks for both big- and small-block Chryslers. Most cranks run between $1,200 and $2,000. Forging materials on the market are mostly super-strong 4130 and 5140 or ultra-strong 4340. Both of these steel grades are far better than the factory's 1051, 1055, and 1056 steel of days past. Generally, 4130/5140 steel is more than anybody needs for a street/strip machine, and 4340 is pretty much a hardcore race-only steel. With aftermarket cranks, you get what you pay for. You can expect the higher dollar cranks to be lighter, with more machining features like windage-controlling winged throws and special hardening applied to the entire crank. Less expensive cranks will tend to be nothing more than copies of the basic design with elongated arms, and on the heavy side. One thing to look for are the previously mentioned radiused journals in any event or budget.

The other stroker crank option is to have your stock steel crank stroked by welding up the rod journals and then remachining everything. The regrinding, after the welding, puts desirable radiused ends at the ends of the journal, and it's entirely possible to have the crank Nitrided, too. The welded cranks are altogether acceptable for engines making less than 600hp without a blower. That's most of us. Precision Crankshaft Grinding offers this service for anywhere between $700 and $950 for most cranks. Besides the obvious cost-cutting amount, are there any other advantages to getting your OEM steel crank weld-stroked? Yessir! The balance factor. Going back a bit, the less expensive forged stroker cranks need lots of expensive Mallory metal to get the balance factor dialed back in. Unfortunately, the heavy Mallory makes the engine rev slower-not good in the quest for power. You can have a fat crank lightweight machined, but the cost jumps. High dollar forged cranks are just about as light, and as strong as you're going to get so they'll use less-if any-Mallory. The welded-up jobs are closer to factory balancing specs after all the welding and machining, so they'll use far less Mallory than the "inexpensive" forged strokers. As stated, you get what you pay for, so shop around and spend your money wisely.

B-engines can easily handle stroker cranks out to the 4.2-inch area, more with cautious clearancing and rods like the Eagles. While 4.375 inches of stroke is possible, you'll definitely need the aftermarket rods to clear everything. Keep in mind, though, the longer the arm, the poorer the rod ratio. When we start going to rod ratios like other guys use, we'll break parts, too. On the street, or the brackets, 500 inches is just about ideal for a low-rev big block. Small blocks around 400 inches are borderline. Either big- or small-block strokers will send you on a trip to your local performance chassis shop to help you overcome your new found traction problems.

Low block 400 aficionados, here's an idea: Find a 440 steel crank with a spun main journal. Have all the main journals turned down to B-engine specifications-don't forget to request the radiused journal ends. A little machining here and there and, presto, the 440 crank drops into the 400. With a .060-inch overbore and a 3.75 stroke, your 400 now displaces 456 cubic inches. With low-block rods, the ratio ends up at 1.693. If RB rods are installed (the preferable way to do this operation), the rod ratio checks in at an OEM 1.8. Custom pistons will need to be used either way. Why do this instead of buying a 440? Here's a couple of things to consider. A B-engine block is stiffer than that of an RB, so there's less shifting and twisting under stress. It's also lighter and sits a little lower under the hood. Header manufacturers make one set of pipes to fit both engines. On a 440, those headers fit much tighter around the K-frame and chassis parts than on a B big-block. A-Bodies with big block conversions would fit just a little better. And if you really want to blow a few minds away, it's still going to have the looks and markings of a low block on the outside. Can you spell sleeper?

Big-block mavens be warned; avoid those old Top Fuel/Funny Car cranks. Alcohol engine cranks too. Yes, they can be had cheap but, most likely, inspection will reveal cracks in crucial areas, making their use a crap shoot. The operative word being crap. Mostly, you'll want to steer clear of them because they have no flex plate/flywheel locator ring at the rear flange. It's possible to have a locator ring welded on by an establishment like Precision Crank, but that's not going to make a questionable crank better. They're for sale cheap for a reason, none good most of the time.

A-Engine fans start out with the best overall rod ratio of any production Chrysler, 1.85-a Street Hemi is "only" 1.83. This means there's a little more available for crank journal stretching. Common small block strokers go from .250 inch longer than stock and climb upwards in increments of .100 inch. TICO Racing offers a full 4.00-inch forged stroke crank with all the good stuff done to it for the heart attack serious, or the person who wants an over 400-inch small block. On a 4.100 bore (.060 inch overbored 340) you'll get 422 cubes out of your small block with bob weights 700 grams lower than a 426 Wedge. Wow! Talk about an engine that revs quick and has tons of low-speed power!

Pistons, Pins, And Rings

Like the specialty crank, forged custom pistons aren't going to be cheap, but their benefits are considerable. To start, a custom piston can be machined with any compression ratio you want and tailor-fitted to your specific engine. There's no limit to what can be done with the custom piston. Ross Racing Pistons offers all sorts of machining operations that can be performed on these beauties that off-the-shelf pistons can't provide. It's possible to have a dish (reverse dome) cut in the top which will aid combustion chamber swirl, ring grooves can be juggled up or down, non-nitrous engines can have more metal machined out of non-critical dead space areas for lightening of the reciprocating end, and the list goes on and on.

Right from the get-go, a long arm engine is naturally going to have a shorter, lighter weight piston, which usually means a faster revving engine. Lighter pistons impart less reciprocating weight, and stress, on the small end of the rod and crank journal. Can't do that with OEM replacement slugs. You can even have your rods re-bushed down to common stock .990-inch pins in big blocks and .927-inch pins in small blocks that will further reduce the weights, just like the Pro Stockers do. This will not only lighten up the piston/rod assemblies greatly, but cut down on balancing cost when the machinist starts to calculate Mallory into the forecast.

Stock pistons and OEM replacement pistons (cast or forged), wrap 5/64-, 5/64-, by 3/16-inch rings in the grooves. The custom-forged piston, a necessity for a stroker motor, can be had with low tension and less parasitic drag ring sets of 1/16, 1/16, and 1/8-inch. These thinner ring sets seal precious combustion and control oil contamination as well as the fatter counterparts do, plus they increase horsepower a bit more due to the lower drag coefficient.

The Oiling System

A proper oiling system is far more important to a stroker engine than a stocker. Melling has done many extensive studies on the oiling of Chrysler engines. Let's look at some of those studies.

At 6,000 rpm, the outer edge of a 440 crank is spinning at a speed of 109.34 mph. Increase the stroke to 4.25 inches, and the outer edge of the crank zips up to 118.25 mph. (stroke + rod journal diameter x 3.1416 x rpm x 60 minutes per hour, divided by 63,360 inches per mile = mph @ outer edge of the rod journal). If you left the stock oil pump, pick up, and pan on your stroker, you'd be asking the oiling system to spread out over hundreds of inches of additional travel with the same amount of oil as a stocker. Does that sound safe? Remember, there's 63,360 inches in a mile. Stroke a 440 one half inch, like the above example, and your oiling system would have to cover the equivalent of 564,537 more inches of surface area @ 6,000 rpm.

The good news is this: You don't need to go hog wild when you build an oiling system for your long arm engine. Actually, it's quite basic. Just slap a high-volume pump on your A or B/RB/Hemi like one of Melling's, or Mopar Performance's finest, and install a windage tray if your engine doesn't have one. Stock stroke windage trays will not clear the swing rods, so either cut and weld your old one or see Milodon for a windage tray that works with your (B/RB) long arm motor.

It's highly recommended that all B/RB engines drill, tap, and install an oversized Hemi oil pick-up and pan. Now your pick up can draw in as much as your oil pump can deliver to the needed areas. You could also have a welder section your old pan to accommodate the Hemi pick up. For A motors, consider having a welder build a kick out in the pan to add more capacity. Then you won't have to extend the OE pick-up or buy a special pan and pick-up assembly. If you plan to spin your stroker much past 6,000 rpm, it's also wise to drill out the oil galley in the block's main saddle a size or two past stock. Only drill out the passages that angle towards the cylinders, not the passages that go up towards the cam. Just squirt a little ATF down the galley and take your time when you drill it out. If you break a drill bit in the oil hole, you'd better start looking for another block. Don't forget to get a hardened intermediate shaft from Melling or MP, and your Mopar engine is done.

Camshafting And The Induction System

Making a deeper cylinder means filling it with more mixture, plain and simple. Stock-stroked A-Engines that ran fine with 270-280 degrees of (advertised) duration should be upgraded by another 10 to 15 degrees. If your big block has been expanded to the 500-inch zone, cams with 300 to 310 degrees of (advertised) duration are the ticket. Cam lift, on the other hand, is less important to cylinder filling than overall duration and seat-to-seat timing. When it comes right down to it, lift has more to do with piston-to-valve clearance and where your heads reach a dead spot in the flow curve.

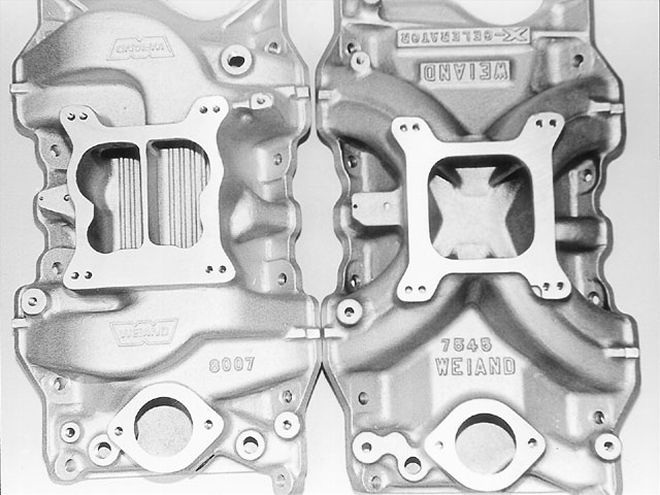

"X" type, single-plane intake manifolds keep deep-breathing strokers from getting a bad case of upper rpm asthma. Weiand's X intakes provide quick, clean throttle response and great breathing without compromising torque or horsepower.

"X" type, single-plane intake manifolds keep deep-breathing strokers from getting a bad case of upper rpm asthma. Weiand's X intakes provide quick, clean throttle response and great breathing without compromising torque or horsepower.

Long arm engines naturally respond exceptionally well to porting. Of all the concerns regarding engine expansion, porting is the single most important step that effects a stroker's high rpm breathing ability (horsepower). It's a given that stroking will multiply torque at low speeds. However, getting it to breathe at higher rpm is what separates the contenders from the pretenders. Without the correct flow work done, the cylinder heads become a bottleneck for breathing and your engine gets a case of high-speed asthma. The recommendations for pumped-up A-Engines is to get the intake flow up past 240 CFM (measured at 28 inches of H20 depression) at .500 inches of cam lift. Big-block strokers should have their porting services provide at least 265 CFM at .500 inches of lift. In both cases, these numbers are reached with more than a gasket match and bowl job. You'll need big valves, intake and exhaust, and a good-guy port job. If you do your own porting work, at least have a professional porting service check your work to insure the ports are flowing high enough numbers and the balance is equal from port to port.

Here's a tip about porting services: Find one with a flow bench designed to measure big-time flow numbers at 28 inches of H20 depression. Don't use a service that runs a wimpy little bench that can only take measurements at 5 or 10 inches of H20 and then converts those numbers to 28 inches of H20. The small flow benches have difficulty finding minute changes and don't draw air through the ports well enough to get solid readings.

Long-crank engines are going to draw tremendously more mixture through the ports, so high-end breathing, as we said, is paramount. If we consider the intake manifold as part of the breathing apparatus, it becomes easier to understand why we can rule out the dual plane manifold. The dual plane (a.k.a. 180-degree intake) is a low rpm torquer out of the box-that's something a stretched crank engine doesn't need more of. Like the mandatory porting job, a better choice for a street/strip engine would be a single-plane intake. A single-plane manifold inhales much better above 4,500 rpm because all the runners draw off the same unrestricted plenum, there are no flow-stalling turns in the ports, and all have shorter runners than the dual plane jobs.

Now, what about the carb? Well, if you're running at least a 750 cfm on your small block, or an 850 on your big block, you'll be ready to rock. If not, you should. Those enlarged cylinder bores are going to create nano-second venturi booster reaction on almost any carb. That's great for instantaneous throttle response and ground pounding torque.

Conclusion

You don't have to dial the 1-800-Psychic hotline for stroker engine building tips. They're constructed the same way any true high-performance engine is built. The only items that warrant concern are the induction system and clearancing for the rods. If you're starting an engine build from scratch, figure the extra money for the long arm crank and the custom pistons as the major difference. So how can you save money by building a stroker? First off, because of the astonishing low-end torque enhancement, deep gears aren't required to get off the line. The money you save on gears and labor could go into porting. Secondly, and more importantly, strokers are generally quick-revving, under-6,000 rpm engines. And therein lies their greatest asset. With the low maintenance comes a very easy-to-live-with engine. No high-strung, high-winding, hard-to-tune powerplant here. Just the best compromise between dollars spent per foot-pound gained.

Mr. Tipz Sez: Let's Go With The Flow

Holley has come through for us performance builders again. It used to be that ya got yerself a bigger carb to go faster and all you ended up with was lost vacuum. Stab the gas and the engine would run into a wall of Jell-O, then all of a sudden take off like a scalded dog. 'Course, when that happened, yer competition rocketed by ya and you'd play catch up. See, those bigger carbs had bigger venturi openings and there wouldn't be enough vacuum to pull and tug in all the proper places at the right time.

Shazam! Those day's are over. Holley released a new carb a few years back that just about borders on the unbelievable. This puppy is 950 cfm and gets its monster-sized flow rating from having smaller upper venturies than an 850 carb. It is real possible to use the new hp carbs on both small and big blocks because the high-velocity venturies are always supplying a vacuum signal to the boosters. Not only is that good for eliminating the low-speed bogging blues but, reaction times against the 'Tree improve dramatically. Go to an aftermarket carb modifier and you'll pay $750 to get that kinda performance from a modified used Holley. Now, you can save a few hundred by going direct to Holley for a new, warranted carb! Now, these hp carbs don't come through with chokes, so ya don't want to use them year 'round. Even though the new 950 hp carbs are labeled as "Race Only," there sure are a lot of streeters and bracketeers using them, particularly high horsepower engines and stroker motors.