In the December 1988 issue, HRM investigated Holley's new Pro-Jection electronic throttle-body fuel-injection system. Pro-Jection simply replaces the carburetor, and most everything else stays put. Then, it was available only with a 670cfm two-barrel TBI, although author Marlan Davis hinted that a four-barrel version was in the works. Less costly and easier to install than the more elaborate multi-point EFI, Pro-Jection has won the hearts of thousands of hot rodders looking for better performance and fuel economy without breaking the bank or requiring a complicated revamp of their induction systems.

The original four-bolt 455 H.O. hosts ported Ram Air III heads, a vintage Doug Nash single-plane intake manifold, and a new 4Di EFI system. The Nash intake is taller than the cast-iron stocker, but the Holley throttle body is shorter than the original Quadrajet, so Droulard used a 1/2-inch spacer to keep the shaker air-cleaner assembly in proper position.

The original four-bolt 455 H.O. hosts ported Ram Air III heads, a vintage Doug Nash single-plane intake manifold, and a new 4Di EFI system. The Nash intake is taller than the cast-iron stocker, but the Holley throttle body is shorter than the original Quadrajet, so Droulard used a 1/2-inch spacer to keep the shaker air-cleaner assembly in proper position.

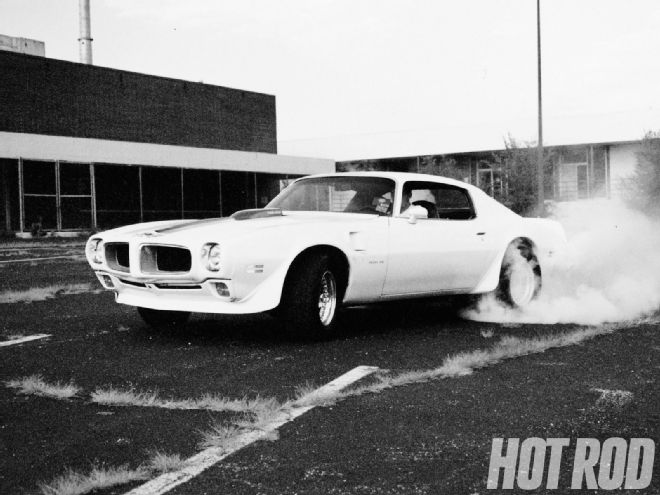

Pontiac enthusiast Dave Droulard, of West Bloomfield, Michigan (and proprietor of Safety Auto Center), is one of those clear thinkers, and we caught up with him on the '98 Power Tour. When we saw his immaculate (and extremely rare) '72 Trans Am, we assumed it was carbureted, but a close eye revealed "fuel injection" logos just below the 455 H.O. markings on the shaker hoodscoop. We traveled more than 200 miles in the injected 'Bird, and despite its 12.9:1 compression ratio and 0.625-inch-lift cam, we found its street manners to be quite civilized. Droulard did inform us that total timing was a scant 16 degrees BTDC in order to keep the pump-gas engine out of detonation.

Droulard has used Pro-Jection for more than four years and praises its ability to increase fuel economy, to reduce exhaust emissions, and, most importantly, to lop nearly a second off his quarter-mile e.t. His working knowledge of the analog Pro-Jection made him the ideal candidate for evaluation work on Holley's recently introduced 4Di (four-barrel, Digital, interactive) system.

The conversion from analog to digital necessitated a 2-inch hole in the firewall to accommodate the Holley wiring harness. A rubber grommet fills the void and insulates the wires from vibration.

The conversion from analog to digital necessitated a 2-inch hole in the firewall to accommodate the Holley wiring harness. A rubber grommet fills the void and insulates the wires from vibration.

Although Holley continues to offer analog systems in two- and four-barrel configurations, 4Di throttle bodies are available with flow ratings of 650 cfm (150 to 300 hp), 700 cfm (225 to 400 hp), or 900 cfm (350 to 500 hp). Because of its healthy displacement and heavily ported Ram Air III heads, Droulard chose the largest of the three throttle bodies, which is fitted with four 85-lb/hr injectors.

Before going digital, we'll detail the Trans Am's previous analog system, so we can see where changes and improvements have been made. The analog Pro-Jection is an open-loop design, which means that there is no oxygen sensor to provide the ECM with feedback data on how much unburned fuel remains after combustion. Instead, the ECM tailors its fuel-delivery signal based on throttle position and engine rpm. The remainder of the fuel requirements are preprogrammed and based on typical requirements for a stock to mildly modified V-8 application. Extra fuel distribution is provided by rotary switches on the ECM to fine tune the power, midrange, idle, accelerator pump, and choke settings in a range that approximates six or seven conventional Holley jet sizes.

A Holley fuel pump and filter are plumbed directly into the stock fuel system. Relatively low 15psi operating pressure eliminates the need for special hoses and fittings.

A Holley fuel pump and filter are plumbed directly into the stock fuel system. Relatively low 15psi operating pressure eliminates the need for special hoses and fittings.

According to Droulard, the analog-choke, accelerator-pump, idle, and midrange tuning procedure was pretty straightforward, but he had to do quite a bit of work with his exhaust-gas analyzer to arrive at the best power-mode setting. Also, the analog ECM seems to balk when the engine is capable of more than 80-percent volumetric efficiency. With race-ported heads, a Doug Nash intake, and a hot roller cam, Droulard's 455 is well above that number, and at wide-open throttle (WOT), the limited tuning range of the ECM and open-loop system were not able to instruct the injectors to stay open long enough to provide adequate fuel. Consequently, a mild lean condition hampered top-end power output slightly but was not severe enough to cause damage. None of this would be experienced with a milder motor where manifold vacuum and volumetric efficiency would be lower.

Close the Loop Because it is based on many of the same design principles, the swap from analog to digital Pro-Jection isn't difficult and takes about four hours. The main differences are sensors, which elevate the system to closed-loop status and a much more powerful digital ECM capable of processing all the extra data. In a closed-loop system, an oxygen sensor in the exhaust stream provides a direct indication of how rich or lean the fuel mixture is. The computer uses this input to add or subtract fuel-injector pulse time so that proper air/fuel ratio is maintained. Another component absent on the analog system is the manifold absolute pressure (MAP) sensor, which reads air-pressure levels within the intake manifold so that the ECM can calculate how much air is being ingested as an indicator of how hard the engine is working.

Droulard distanced the MAP sensor from the engine to limit vibrations, which can shorten its life cycle. A delicate diaphragm and internal electronics translate manifold vacuum into an electrical-frequency signal read by the ECM.

Droulard distanced the MAP sensor from the engine to limit vibrations, which can shorten its life cycle. A delicate diaphragm and internal electronics translate manifold vacuum into an electrical-frequency signal read by the ECM.

A Throttle Position Sensor (TPS) is used in both analog and digital systems, but the one in the digital system is more sensitive and is able to read the amount and the rate of throttle opening. With input from the MAP and the high-sensitivity TPS, the ECM discerns the difference between a slow rise in throttle position versus a quick one so that the accelerator-pump fuel-supplementation graph can prevent bogging on hard, sudden acceleration. Conversely, the sensors provide information concerning rapid deceleration-the butterflies snap shut, and the manifold vacuum shoots up as the engine rpm drops off. The sensors in the 4Di system detect this sudden throttle closure and respond instantly with reduced fuel delivery to eliminate an overrich condition.

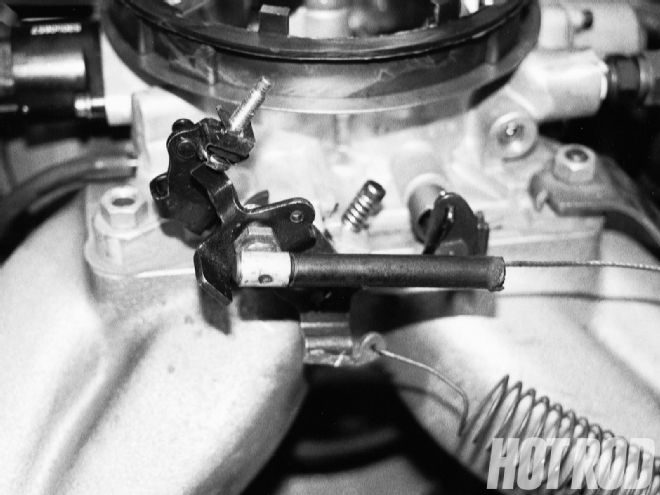

A simple throttle bracket and cable are a function of the TH400 automatic, which uses manifold vacuum (rather than mechanical means) to actuate the transmission's throttle pressure valve, simplifying the installation.

A simple throttle bracket and cable are a function of the TH400 automatic, which uses manifold vacuum (rather than mechanical means) to actuate the transmission's throttle pressure valve, simplifying the installation.

If you're thinking that the 4Di is a cross between the simplicity of throttle-body injection and the sophistication common to most multipoint systems, you'd be right. With its ability to "refresh" the incoming data 62 to 65 times per second, the 4Di's ECM offers Pro-Jection users the freedom to modify their engines without the fear of exceeding the boundaries imposed by an analog ECM.